High-temperature-resistant plating-resisting coating and preparation method thereof

A technology of high temperature resistance and anti-plating, applied in the direction of coating, can solve the problems of complicated process, pollution of coating, inaccurate filling and coating area, etc., and achieve the effect of simple painting process, high conversion rate of raw materials and good film performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

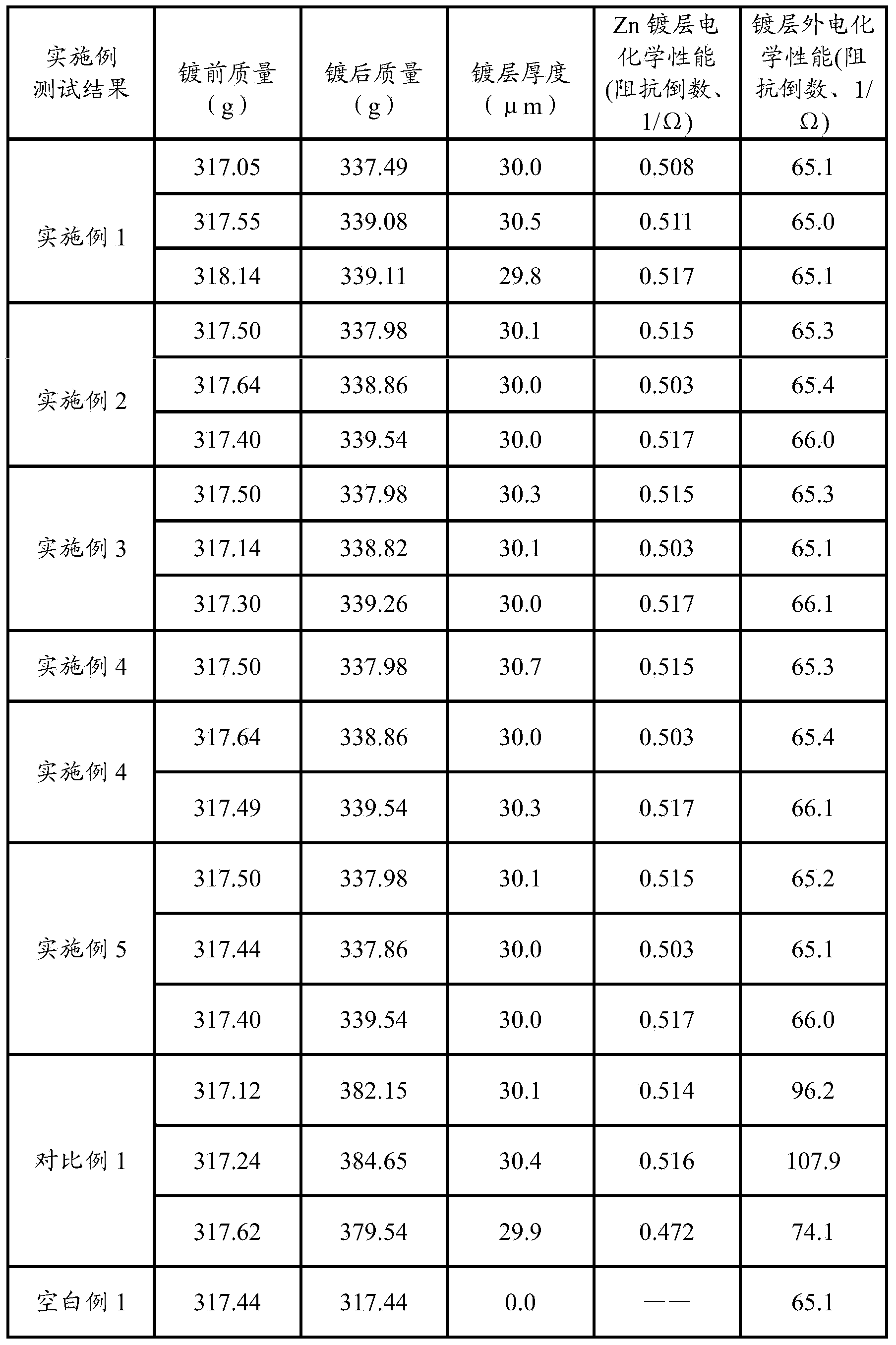

Examples

Embodiment 1

[0027] A method for preparing the high-temperature-resistant plating-resisting coating, comprising the following steps:

[0028] 1) Weigh 68g of high temperature resistant silicone resin, 8g of acrylic resin, 22g of muscovite powder, 12g of copper chrome black and 15g of silicon dioxide, set aside;

[0029] 2) Uniformly mix and disperse high-temperature-resistant silicone resin, muscovite powder and copper chrome black under the condition of 1400r / min to obtain a mixture;

[0030] 3) Then add silicon dioxide into the mixture and fully disperse for 3 hours; then deposit for about 1 hour to obtain a high temperature resistant coating.

Embodiment 2

[0032] A method for preparing the high-temperature-resistant plating-resisting coating, comprising the following steps:

[0033] 1) Weigh 75g of high temperature resistant silicone resin, 6g of acrylic resin, 20g of muscovite powder, 13g of copper chrome black and 17g of silicon dioxide, set aside;

[0034] 2) Uniformly mix and disperse high-temperature resistant silicone resin, muscovite powder and copper chrome black at 1200r / min to obtain a mixture;

[0035] 3) Then add silicon dioxide into the mixture and fully disperse for 5 hours; then deposit for about 1 hour to obtain a high temperature resistant coating.

Embodiment 3

[0037] A method for preparing the high-temperature-resistant plating-resisting coating, comprising the following steps:

[0038] 1) Weigh 55g of high temperature resistant silicone resin, 8g of acrylic resin, 35g of muscovite powder, 12g of copper chrome black and 18g of silicon dioxide, set aside;

[0039] 2) Uniformly mix and disperse high temperature resistant silicone resin, muscovite powder and copper chrome black at 1500r / min to obtain a mixture;

[0040] 3) Then add silicon dioxide into the mixture and fully disperse for 2 hours; then deposit for about 3 hours to obtain a high temperature resistant coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com