Bacillus cereus and probiotics powder thereof as well as preparation and application of probiotics powder

A technology of Bacillus cereus and probiotics is applied in the field of microorganisms to achieve the effects of improving survival rate, low cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A bacillus cereus probiotic powder, its specific preparation steps are:

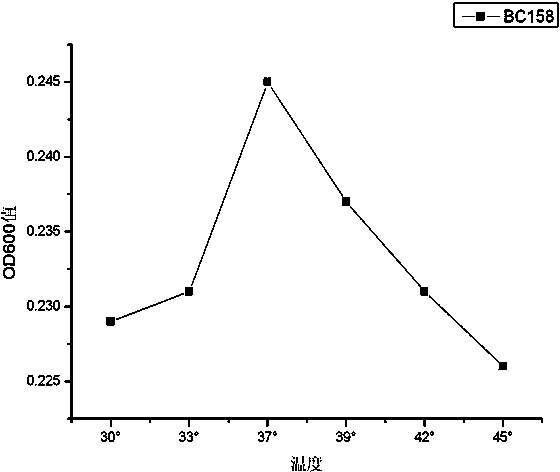

[0048] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0049] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.3% beef extract, 1% peptone, 0.5% sodium chloride, 1.5% agar powder, and the balance is water;

[0050] Step 2, primary seed culture: take the strain 1 inoculation loop prepared in step 1 and inoculate it into a 500mL Erlenmeyer flask filled with 80 primary seed medium, and then culture it on a shaker at 34°C and 220rpm for 10h to obtain First-grade seed liquid, spare;

[0051] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.3% yeast extract, 0.5% peptone, 0.5% sucrose, 0.3% disodium hydrogen phosphate, 0.01...

Embodiment 2

[0060] A bacillus cereus probiotic powder, its specific preparation steps are:

[0061] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0062] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.4% beef extract, 1.2% peptone, 0.5% sodium chloride, 2% agar powder, and the balance is water;

[0063]Step 2, primary seed culture: take the strain 3 inoculation loop prepared in step 1 and inoculate it into a 500mL Erlenmeyer flask containing 120mL primary seed medium, and then culture it on a shaker at 37°C and 250rpm for 16h to obtain First-grade seed liquid, spare;

[0064] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.5% yeast extract, 0.7% peptone, 1.0% sucrose, 0.6% disodium hydrogen phosphate, 0.0...

Embodiment 3

[0073] A bacillus cereus probiotic powder, its specific preparation steps are:

[0074] Step 1, slant solid culture: Bacillus cereus ( Bacillus cereus ) BC158 was inoculated on the solid slant medium, and cultured at 37°C for 24 hours to obtain the strains cultured on the slant solid, and set aside;

[0075] The composition of the solid slant medium is: by mass percentage, the solid slant medium contains 0.35% beef extract, 1.1% peptone, 0.5% sodium chloride, 1.8% agar powder, and the balance is water;

[0076] Step 2, primary seed culture: take the strain 2 inoculation loop prepared in step 1 and inoculate it into a 500mL Erlenmeyer flask containing 100mL primary seed medium, and then culture it on a shaker at 36°C and 240rpm for 14h to obtain First-grade seed liquid, spare;

[0077] The composition of the primary seed medium is as follows: by mass percentage, the primary seed medium contains 0.4% yeast extract, 0.6% peptone, 0.8% sucrose, 0.5% disodium hydrogen phosphate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com