Mud pump damming integrated machine

An all-in-one machine and mud pump technology, applied in the field of check dam construction, can solve the problems of poor working conditions for construction personnel, uneven dam quality, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

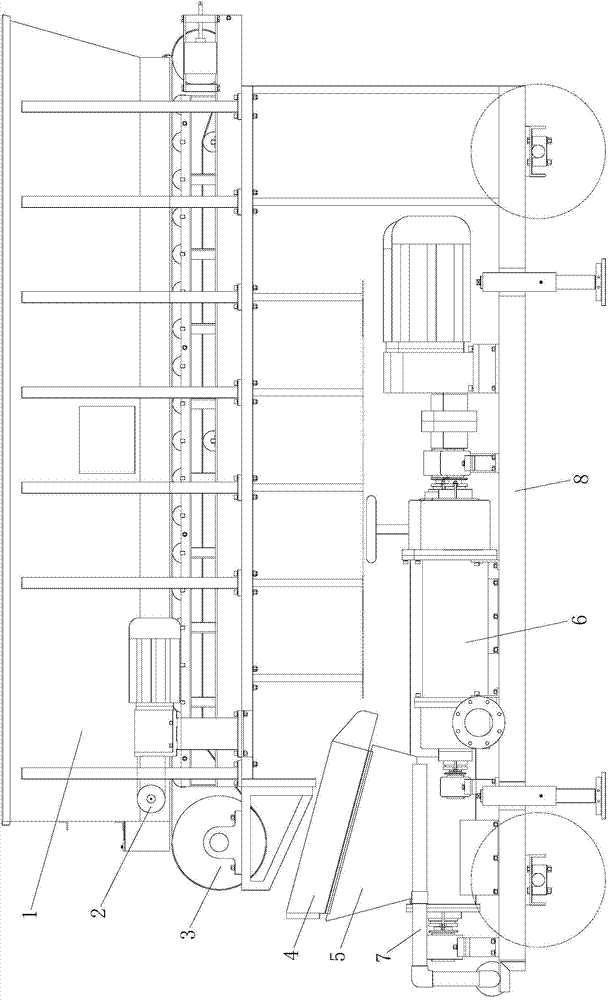

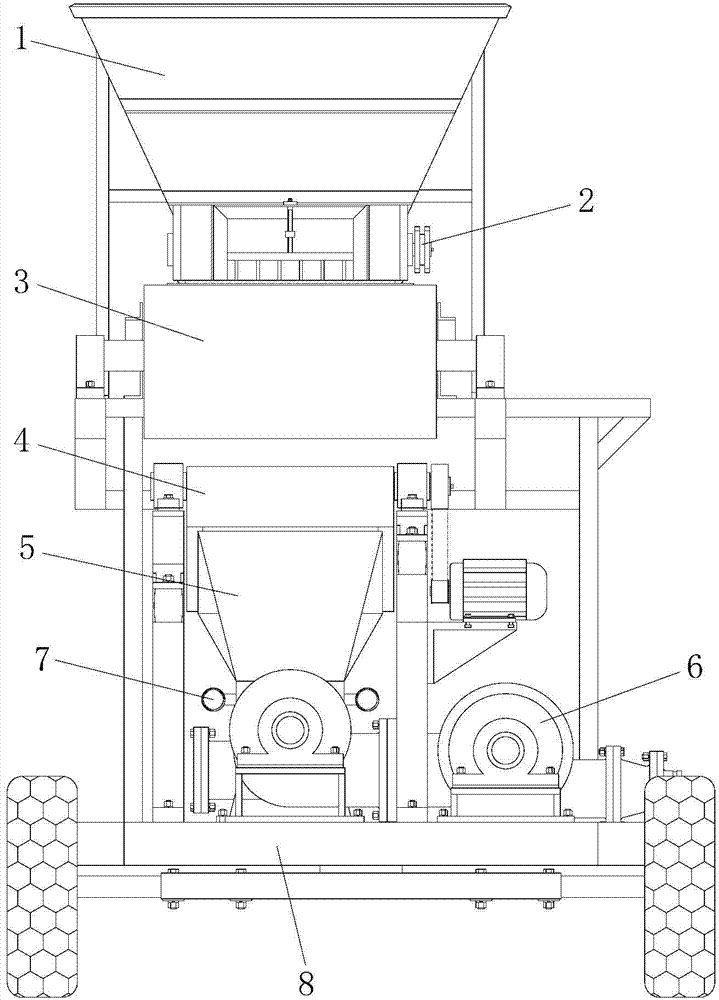

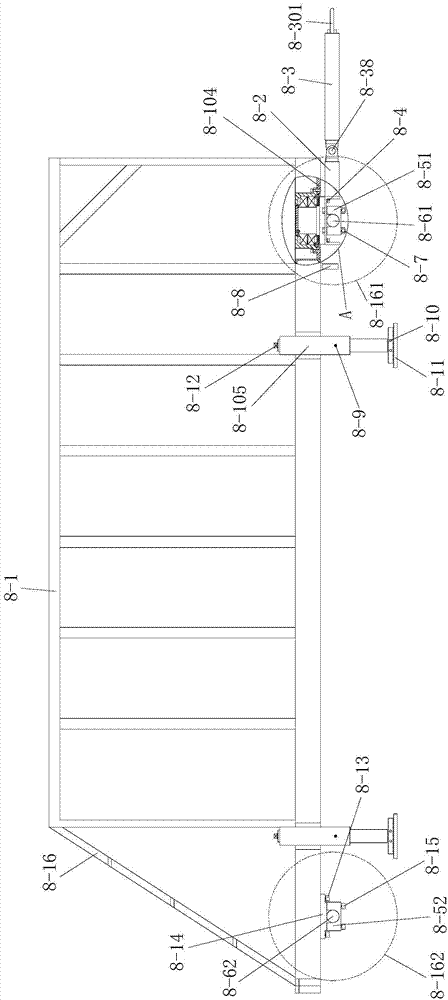

[0152] Such as figure 1 and figure 2 As shown, the present invention includes a vehicle axle 8 and a soil material storage box 1 installed on the vehicle axle 8, a soil material conveying system 3, a soil material vibrating screen 4, a mud preparation device 5 and a mud delivery pump 6, and the soil material One end of the lower part of the storage box 1 and near the discharge port is installed with a soil material crushing mechanism 2 for crushing the soil material to be discharged. The soil material conveying system 3 is located below the soil material storage box 1, and the soil material vibrates The sieve 4 is located below the soil conveying system 3 and vibrates and screens the soil, and the mud preparation device 5 is located below the soil vibrating screen 4 and combines the vibrating and screened soil with the water supplied by the water supply system 7 Mix to make mud, the water supply system 7 is arranged on the bottom of the mud preparation device 5 and communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com