Steam pipeline condensed water soakage pit

A technology of steam pipelines and seepage wells, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve problems such as hindering traffic, destroying vegetation and greening, secondary pollution, etc., and achieves the effects of convenient materials, low price and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

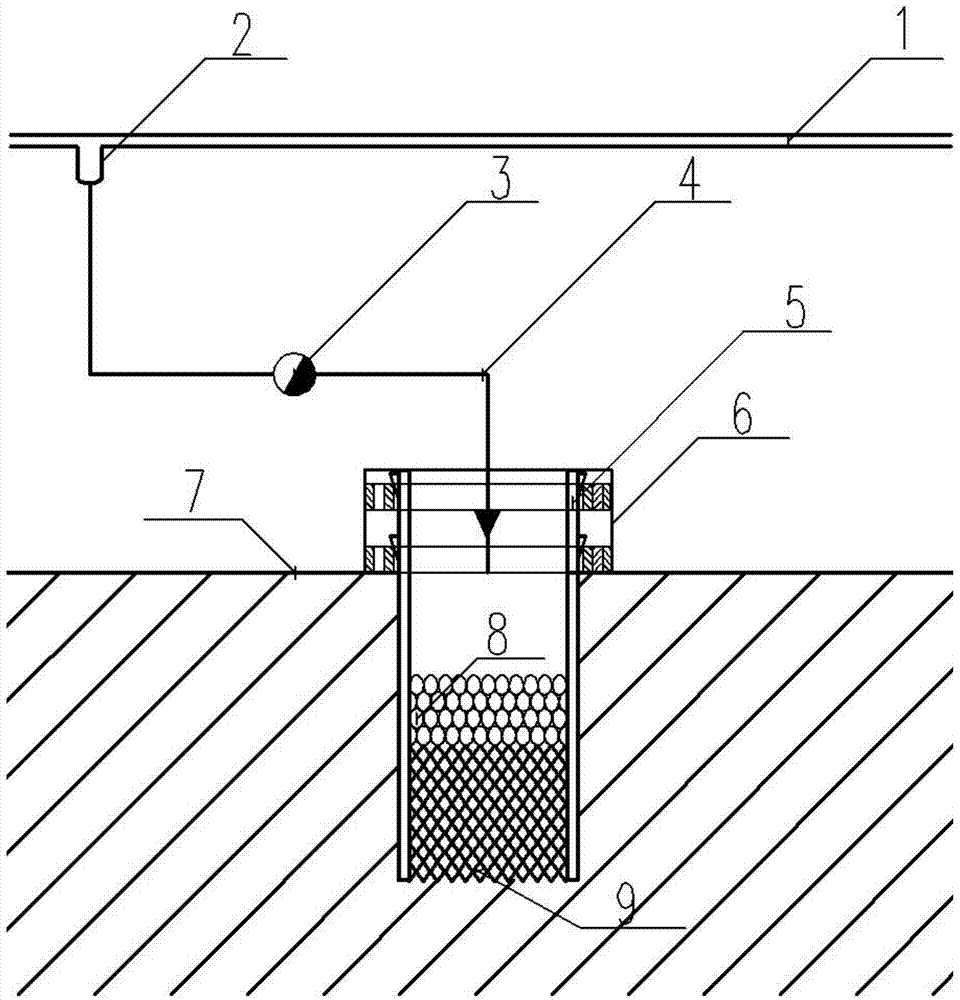

[0015] Example 1: the present invention is made of stainless steel sheet-made drainage seepage well 5, cobblestone 8 of diameter 40mm~50mm, common gravel 9 and personal protection 6 and is made up of, and the seepage well 5 that is surrounded by stainless steel sheet will be higher than ground 200mm, and seepage well is buried in About 600mm underground. First fill a certain amount of ordinary gravel 9 in the seepage well, and then neatly spread several layers of pebbles 8 on the surface of the gravel. Because the cost of cobblestones is relatively high, it is required to ensure that the water discharged from the discharge nozzle 4 is directly splashed on the pebbles. All right; it is required that the accumulation surface of the pebbles 8 be 200mm lower than the ground. The outlet nozzle 4 of the drain valve is 200mm deep into the seepage well, which effectively prevents the injury caused by the discharge splashing. The condensed water from the steam pipe 1 is collected in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com