Industrial hydraulic disc brakes

A disc brake, an industrial technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the inconvenience of friction lining installation and adjustment, easy sticking of force transmission mechanism, low braking reliability, etc. Problems, to achieve the effect of convenient installation and debugging, light weight, easy use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment and accompanying drawing.

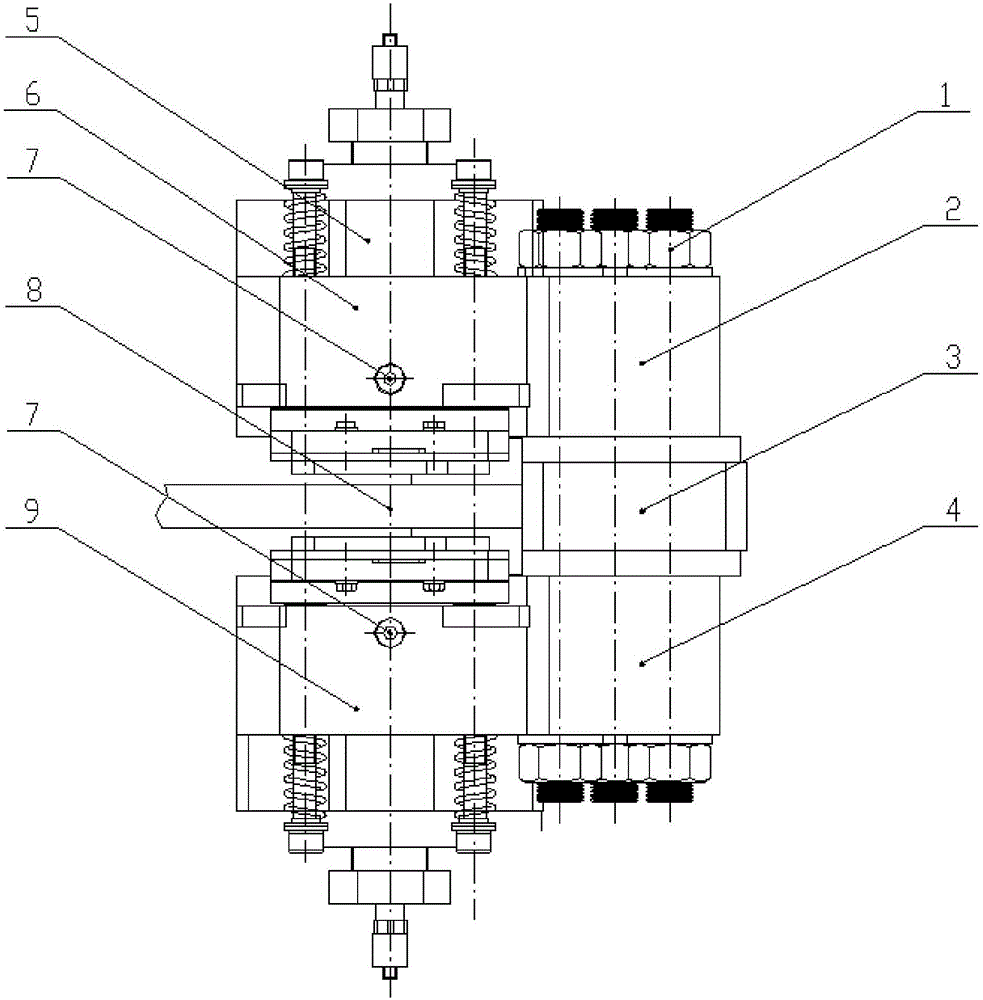

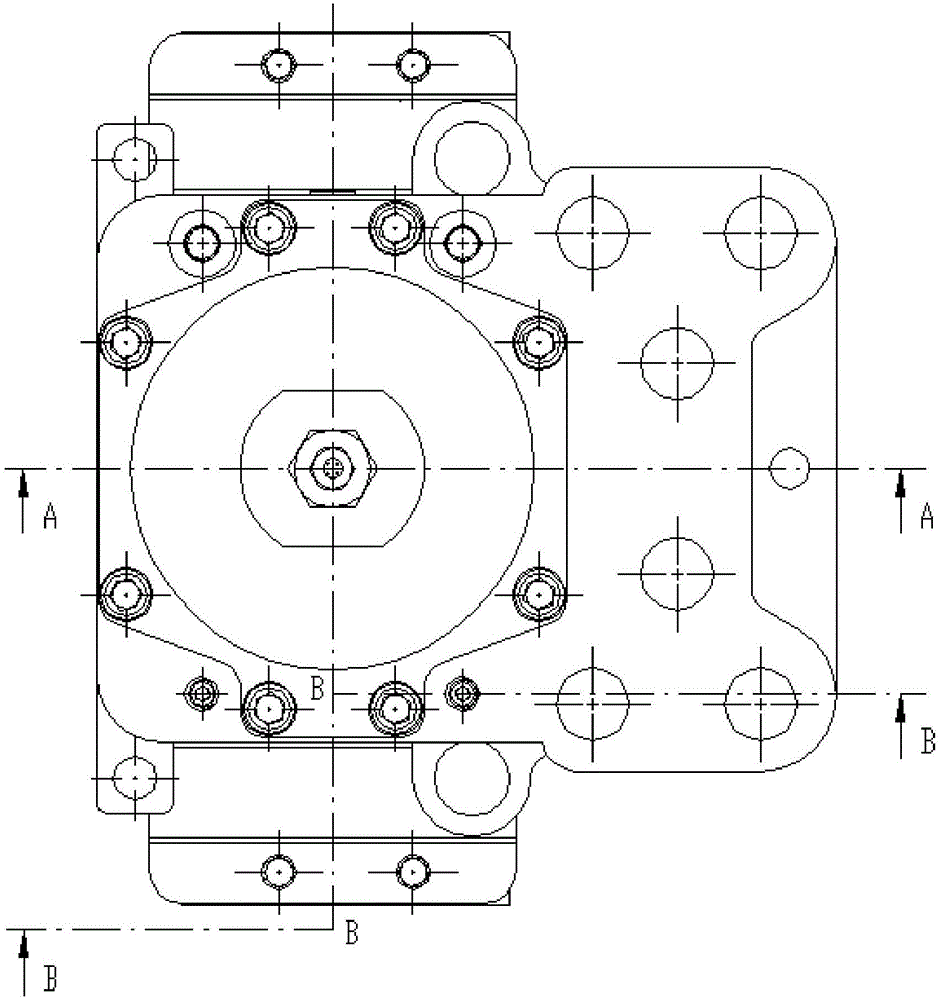

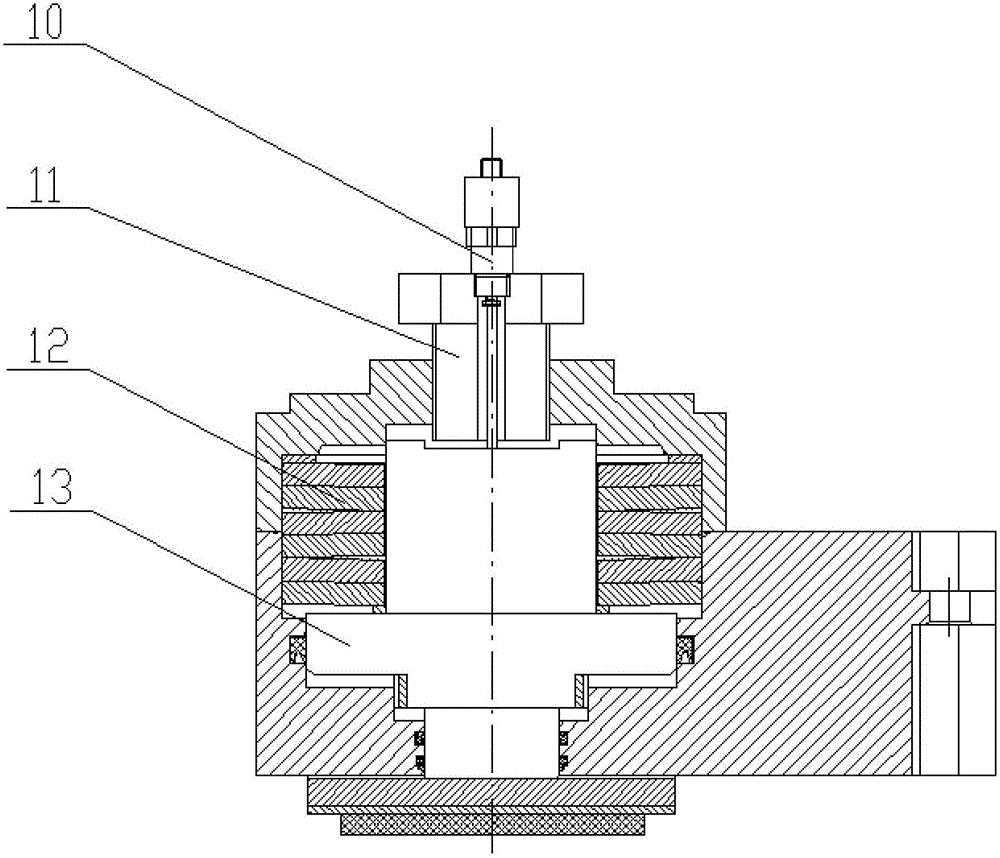

[0023] Industrial hydraulic disc brakes include: left-type brake caliper 4, right-type brake caliper 2 and brake bracket 3, left-type brake caliper 4 and right-type brake caliper 2 have the same structure, including hydraulic cylinder 6 , piston 13, disc spring group 12, upper cover 5, positioning nut 11, indicator 10, spring bolt 15, spring 16, connecting rod 17, connecting bolt 18, brake shoe 19 and friction plate 20, upper cover 5 and oil The cylinder body 6 is fixedly connected by connecting bolts 14, the piston 13 is placed in the hydraulic cylinder body 6, and the hydraulic cylinder body 6 is provided with a pressure oil hole 7, and the pressure oil hole 7 communicates with the oil chamber in the hydraulic cylinder body 6 , the left hydraulic cylinder 9 of the left type brake caliper 4 and the right hydraulic cylinder 6 of the right type brake caliper 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com