Bearing testing device of locomotive traction motor

A traction motor and bearing testing technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as inability to traction motor bearing testing, and achieve the effect of ensuring reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

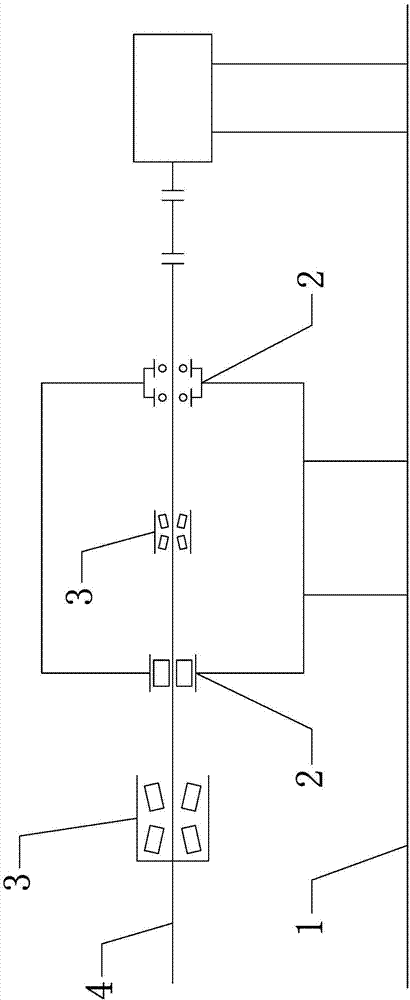

[0021] Such as figure 1 The new test device for locomotive traction motor bearings shown includes: test shafting components, power drive system, lubrication system, dynamic loading system, running wind simulation system, monitoring system for testing experimental data and a bed for supporting the above structure body and platform 1;

[0022] The test shafting components include: test bearing 2, loading bearing 3 and main shaft 4; the test bearing 2 and loading bearing 3 are installed crosswise to support the main shaft 4, that is, the test bearing 2 is installed on the main shaft 4 according to the actual support method of the main shaft of the traction motor, and the loading bearing 3 Install on the corresponding position of the main shaft 4 according to the force bearing mode of the main shaft of the traction motor;

[0023] The main shaft 4 is driven to rotate by a power drive system, and the power drive system is that the motor drives the main shaft 4 to rotate through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com