Reciprocating type pulsation high gradient magnetic separation system matched with solenoid type superconducting magnet

A solenoid-type superconducting and pulsating system technology, applied in the field of magnetic separation, can solve problems such as no patent declaration, and achieve the effects of improving washing efficiency, reducing inclusions, and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

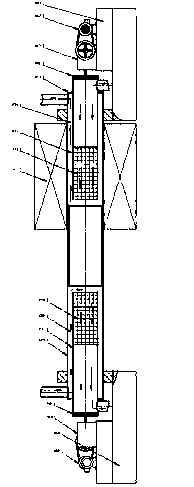

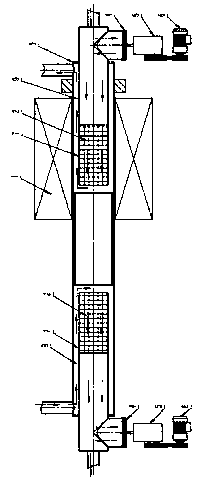

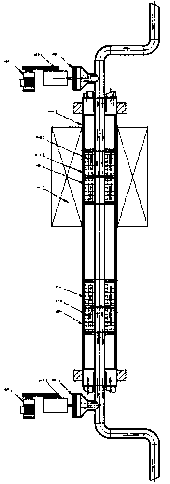

[0019] 1. The following is combined with the attached figure 1 , the pulsation system supporting the reciprocating solenoid type superconducting magnetic separator of the present invention is further described.

[0020] The implementation mode of this embodiment is: figure 1 The axis of the middle superconducting magnet is parallel to the horizontal direction, the pulsating tympanic membrane 4 and the pulsating box 5 are connected through a transmission rod, and the pulsating motor 6 provides power. The pulsating tympanic membrane 4 is directly connected to the end of the sorting chamber inner cylinder 7, the pulsating motor and the pulsating box are placed on the transmission base 8, the tympanic membrane, the pulsating box and the pulsating motor are placed along the axis of the superconducting magnet, and can be reciprocated with the sorting tank. 3 reciprocating movement. In the magnetic separation process, the ore pulp directly enters the high gradient separation cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com