Workbench of cooling fin collecting device

A collection device and heat dissipation fin technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unable to improve production efficiency, single function, and large labor consumption, so as to reduce the labor load of workers and simplify the control Accurate, work-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It is necessary to point out that the following embodiments are only used to further illustrate the present invention, and should not be construed as limiting the scope of protection of the present invention. Those of ordinary skill in the art can make some non-essential features to the following embodiments according to the essence of the present invention. Improvements and adjustments. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict between the features.

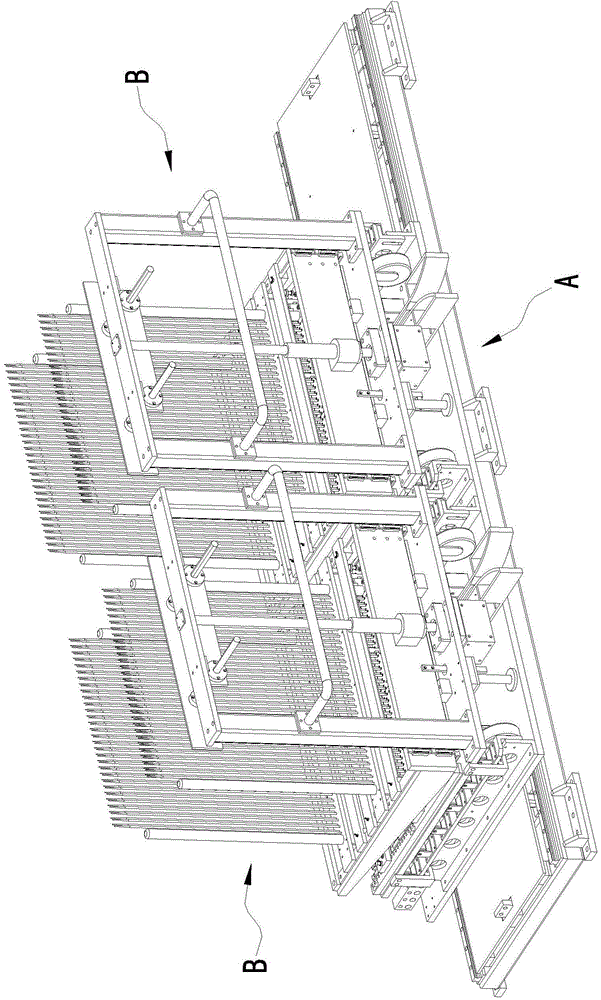

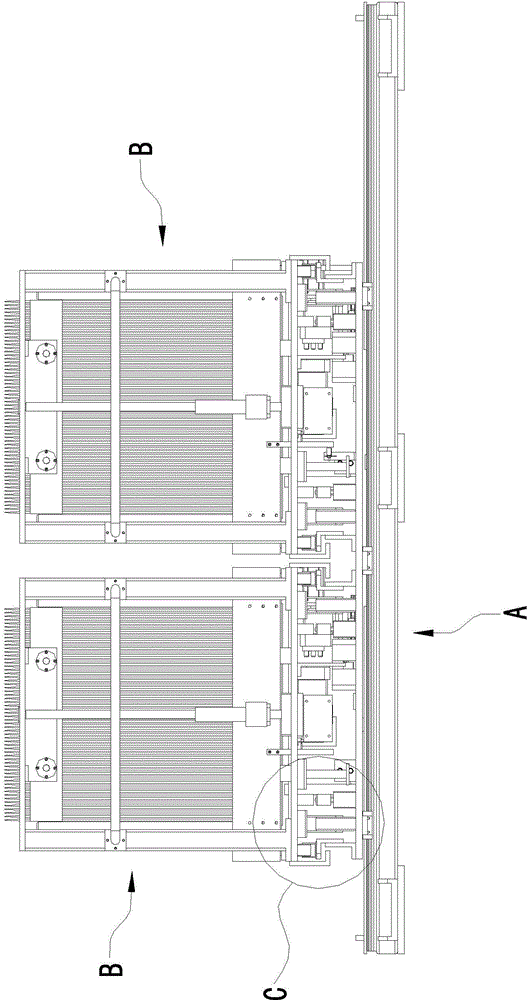

[0038] like Figure 1 to Figure 20 As shown in the figure, an aggregate device for stamping heat dissipation fins includes a worktable A and an aggregate trolley B;

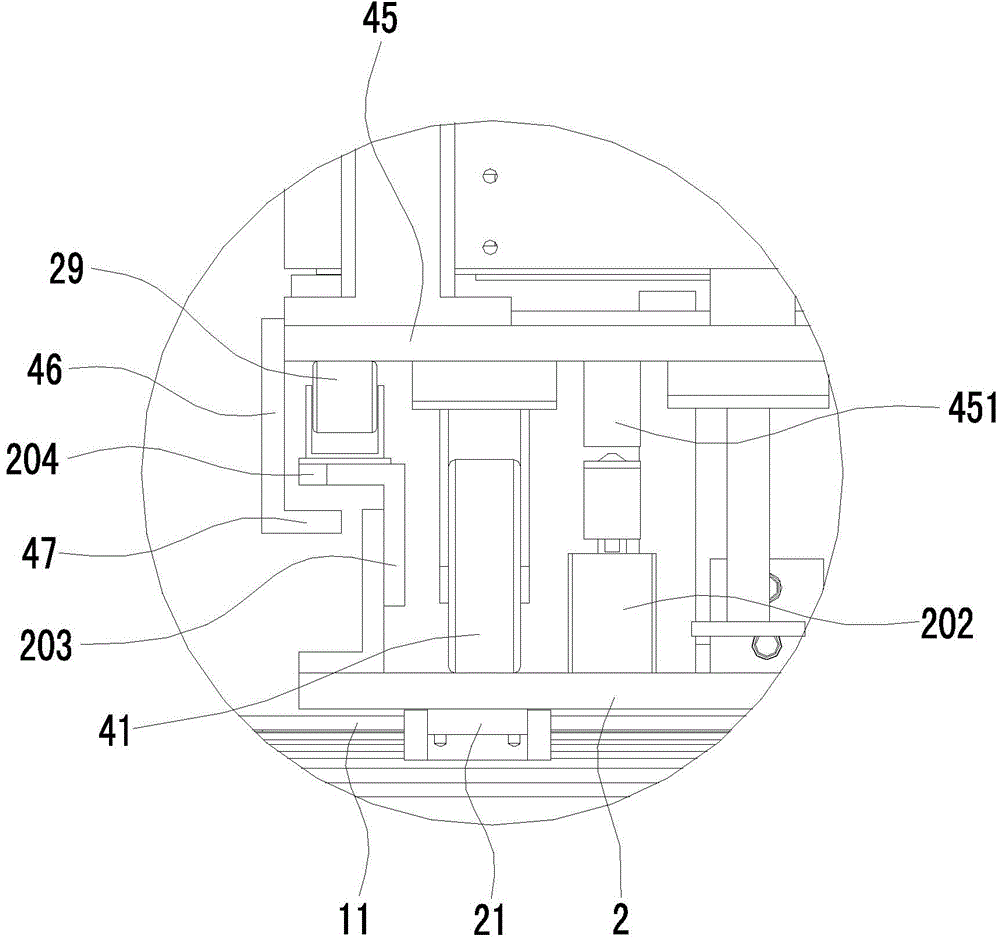

[0039] The workbench A includes a base 1 and a flat plate 2 arranged on the base 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com