Mouth mould and core mould structure of plastics extrusion mould

A technology for extrusion dies and dies, which is applied in the field of dies and core dies, can solve the problems of reduced mold molding surface finish, long production stop time, increased energy consumption of fluid transportation, etc., to achieve improved smoothness and scratch resistance, and improved The effect of smoothness and flatness, low cost of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

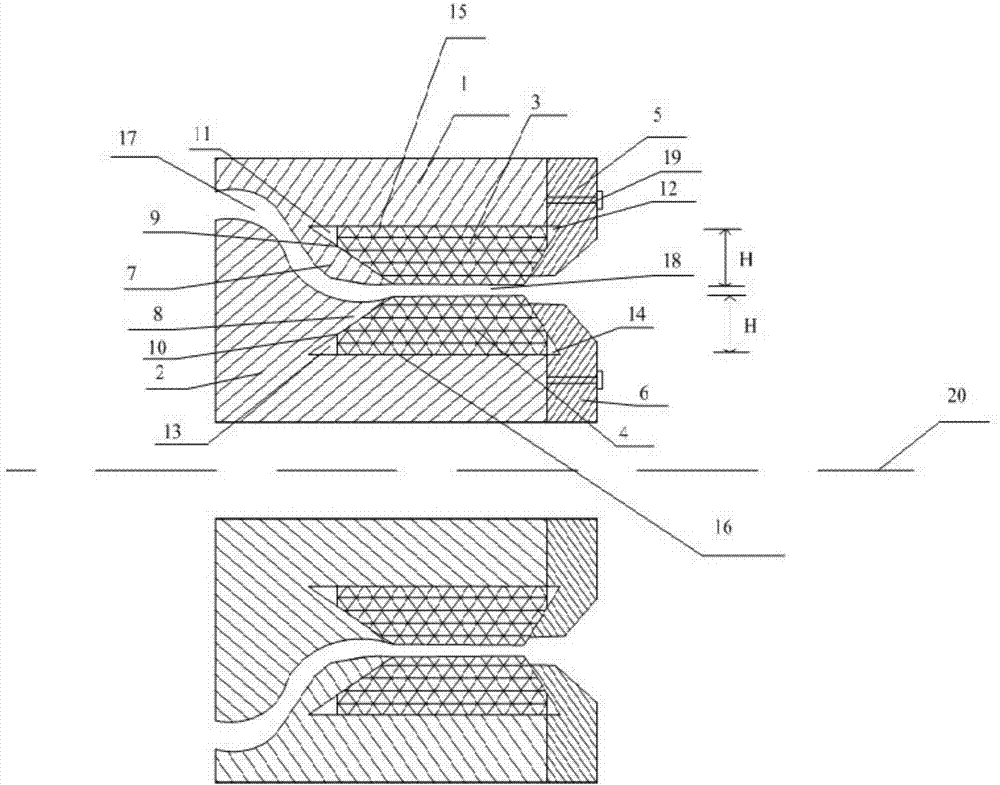

[0023] Such as figure 1 As shown, the die and core mold structure of the plastic extrusion die includes a die 1 made of a rigid material and a core die 2 made of a rigid material, the die 1 is a hollow cylinder, and the core The die 2 is arranged coaxially with the die 1 and placed in the die 1, the inner surface of the die 1 and the outer surface of the core die 2 form a first annular passage 17 for fluid flow, and, in the A die insert 3 is installed on the outlet end of the die along a direction parallel to the die axis, and a core die insert 4 is installed on the outlet end of the mandrel along a direction parallel to the die axis. A second annular passage 18 for fluid flow is formed between the insert 3 and the core mold insert 4;

[0024] Wherein, both the die insert 3 and the mandrel insert 4 are made of polytetrafluoroethylene;

[0025] Moreover, the outlet end of the die is provided with a first groove 15 for installing the die insert; one end of the first groove 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com