Vehicle suspension structure with inerter-spring-damper

A technology for vehicle suspension and inertial container, applied in the field of vehicle suspension structure, can solve the problems of increasing the horizontal space of suspension layout, not on the same axis, and the engineering application value is questionable, so as to overcome the limited space of suspension layout and increase the number of springs. Significant effect of load quality and engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

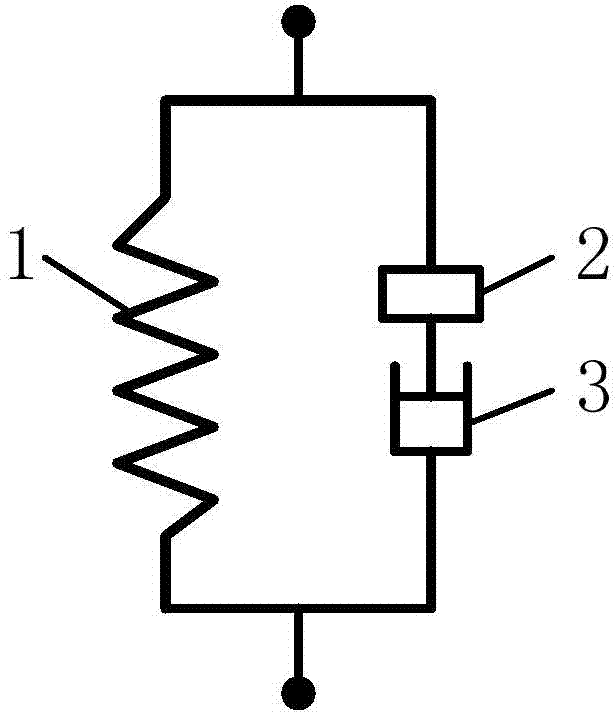

[0023] exist figure 1 Among them, the inerter 2 and the damper 3 are in series structure, and coaxial force and motion. The upper fulcrum of the inerter 2 is hinged with the upper fulcrum of the spring 1, and is connected to the vehicle body. The lower fulcrum of the inerter 2 is connected in series with the damper 3 and then hinged with the lower fulcrum of the spring 1 and connected to the wheel, thus completing the installation of a vehicle suspension structure containing the inerter.

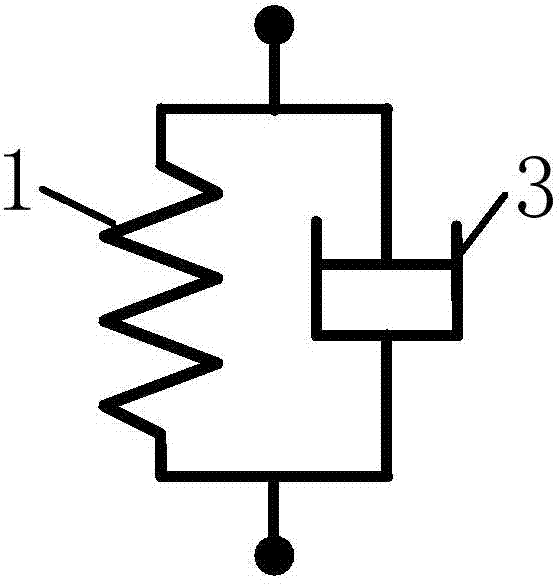

[0024] exist figure 2 Among them, the upper fulcrum of the spring 1 is hinged with the upper fulcrum of the damper 3 and connected to the vehicle body, and the lower fulcrum of the spring 1 is directly hinged with the lower fulcrum of the damper 3 and connected with the wheel. Thus, the installation of the traditional passive suspension structure is completed.

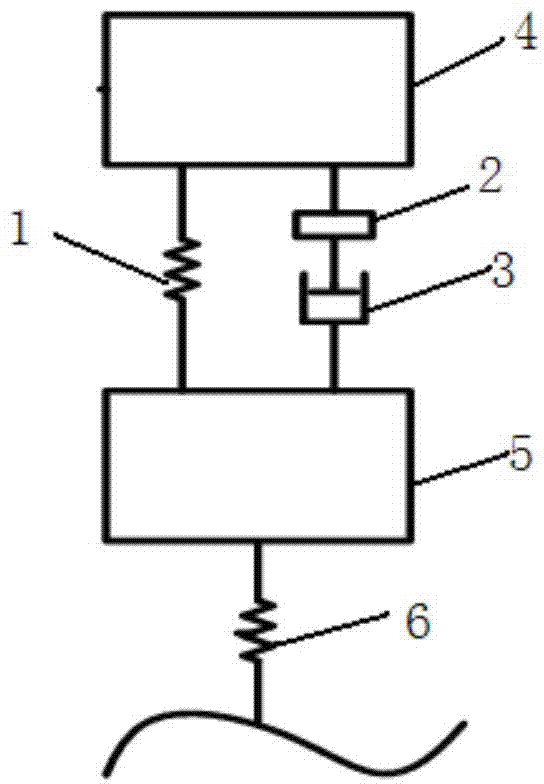

[0025] exist image 3 Among them, the upper fulcrum of the vehicle suspension structure containing the inerter of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com