Hoisting loop integrated module of ship crane hydraulic system

A marine crane and hydraulic system technology, which is applied to cranes, mechanical equipment, fluid pressure actuators, etc., can solve the problems of inconvenient maintenance and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

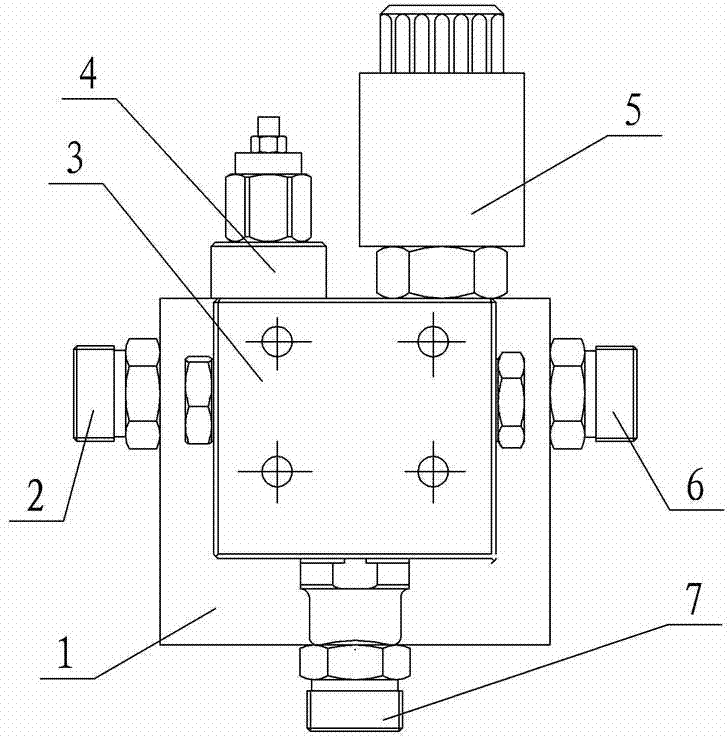

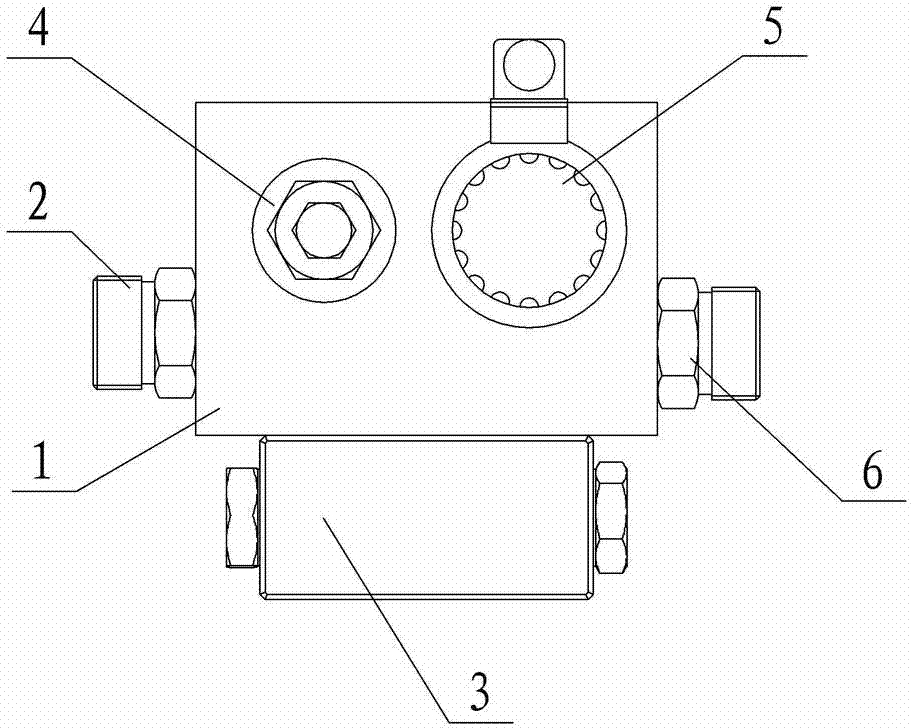

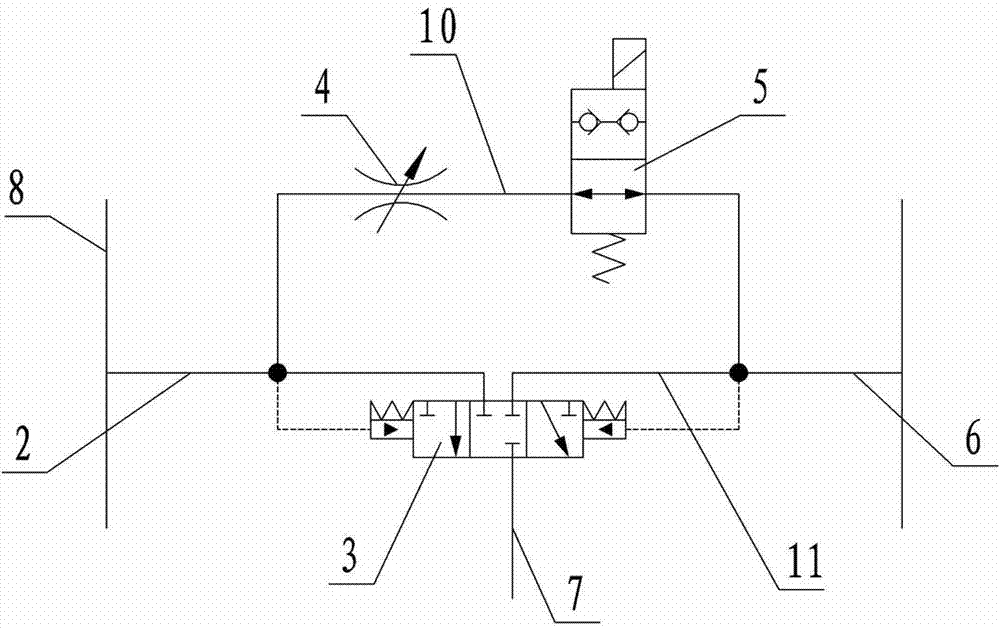

[0012] Embodiments of the hoisting circuit integrated module of the marine crane hydraulic system of the present invention: as Figure 1-3 As shown, it includes a valve body integrated mounting seat 1 used to be connected in series between the two main oil circuits 8 of the system. The valve body integrated mounting seat 1 is a rectangular parallelepiped structure. On its left and right sides, the left oil inlet connector 2 and the right oil inlet connector 6 are respectively connected to the two serial interfaces; a flushing valve 3 is fixed on the upper end surface of the valve body integrated mounting seat 1, and the The throttle valve 4 and the electromagnetic reversing valve 5 arranged in sequence on the left and right are fixed on the front side of the valve body integrated mounting seat 1, and the flushing valve 3, the throttle valve 4 and the electromagnetic reversing valve 5 can all adopt existing technology. The structure of the control valve, wherein the flushing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com