Preparation method of high-performance mould-press type mixed silicone rubber

A technology for mixing silicone rubber and high performance, which is applied in the field of preparation of high-performance molding type mixing silicone rubber, and can solve the problems that mechanical properties cannot meet the needs and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

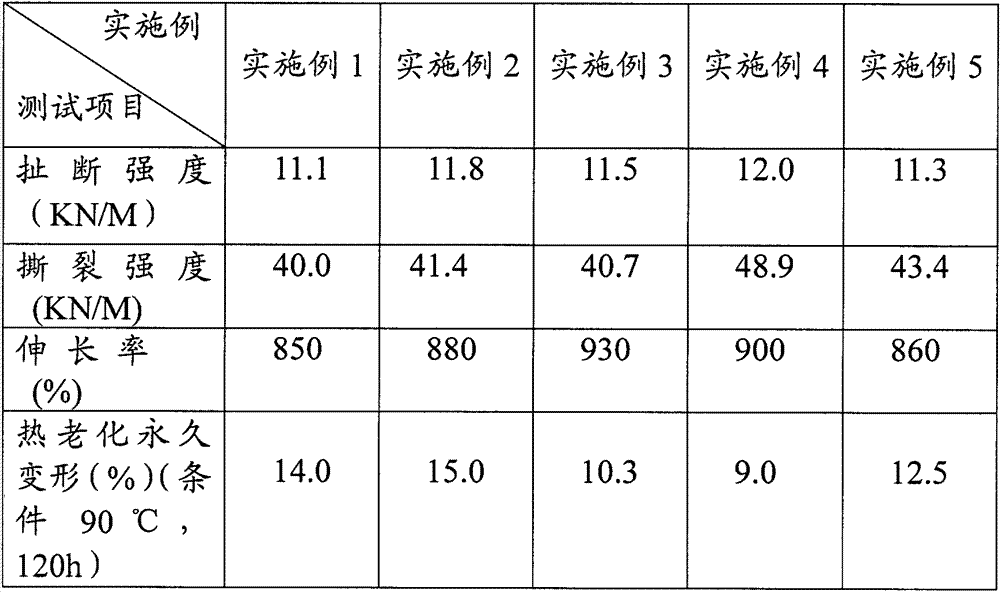

Examples

Embodiment 1

[0023] A kind of preparation method of high-performance molded type mixed silicone rubber: the total amount of methyl vinyl silicone rubber raw rubber is 350kg, wherein the vinyl content is respectively 0.04%, 0.3%, 5% methyl vinyl silicone rubber raw Rubber accounts for 60%, 35%, and 5% of the total raw rubber; the total amount of silicone oil additives is 15kg, hydroxyl silicone oil accounts for 85%, and low-hydrogen silicone oil accounts for 15%; the selected specific area is 300m 2 The white carbon black per gram is 120kg; knead the above raw materials evenly with a kneader, and then put the kneaded rubber material at room temperature for 6 hours; steam to raise the temperature of the rubber to 120°C, and the heating process is controlled within 1.5 hours; after the temperature of the rubber is raised, start vacuuming, the vacuum degree is controlled at -0.04MPa, the temperature of the rubber is controlled at 150°C, and the vacuuming time is controlled at 2 hours , after f...

Embodiment 2

[0026] A kind of preparation method of high-performance molded type mixed silicone rubber: the total amount of methyl vinyl silicone rubber raw rubber is 320kg, wherein the vinyl content is respectively 0.04%, 0.22%, 10% methyl vinyl silicone rubber raw Rubber accounts for 50%, 35%, and 15% of the total amount of raw rubber; the total amount of silicone oil additives is 11kg, of which hydroxyl silicone oil, dimethyldimethoxysilane, and low hydrogen-containing silicone oil each account for 50% of the total amount of silicone oil additives. 50%, 40%, 10%; the selected specific area is 200m 2 The amount of white carbon black per gram is 110kg; knead the above raw materials evenly with a kneader, and then put the kneaded rubber material at room temperature for 1 hour; steam to raise the temperature of the rubber to 100°C, and the heating process is controlled within 2 hours; after the temperature of the rubber is raised, start vacuuming, the vacuum degree is controlled at -0.02MPa...

Embodiment 3

[0029] A preparation method of high-performance molded mixed silicone rubber: the total amount of raw methyl vinyl silicone rubber is 380kg, and the vinyl content is respectively 0.08%, 0.22%, 3%, and 5% of methyl vinyl Silicone rubber raw rubber accounts for 60%, 20%, 10%, and 10% of the total raw rubber; the total amount of silicone oil additives is 18kg, of which dimethyldimethoxysilane, vinyl hydroxy silicone oil, and high hydrogen-containing silicone oil Each accounts for 80%, 15%, and 5% of the total amount of silicone oil additives; the selected specific area is 300m 2 The white carbon black per gram is 125kg; knead the above raw materials evenly with a kneader, and then put the kneaded rubber material at room temperature for 8 hours; steam to raise the temperature of the rubber to 125°C, and the heating process is controlled within 2 hours; after the temperature of the rubber is raised, start vacuuming, the vacuum degree is controlled at -0.06MPa, the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com