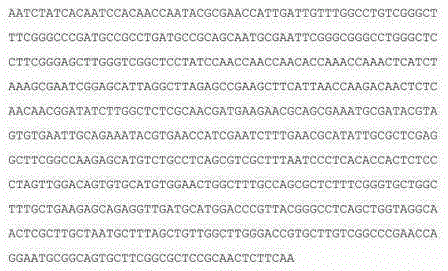

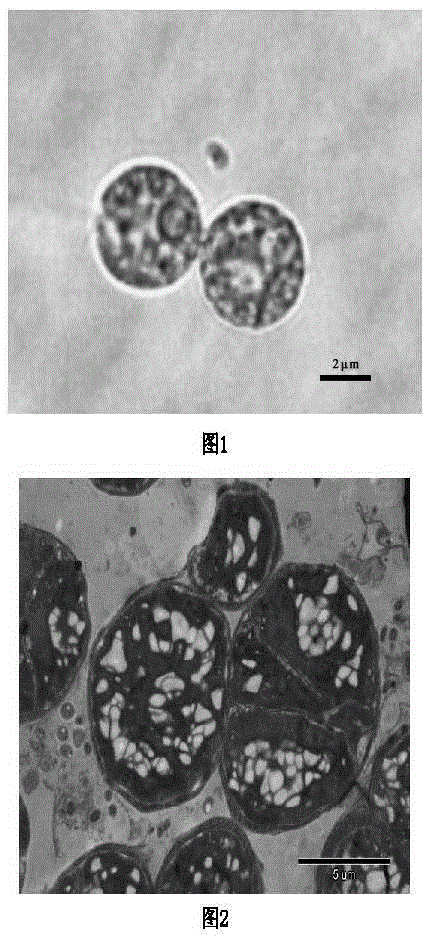

Industrialized culture method of high protein desert green algae

A culture method and high-protein technology, applied in the direction of single-cell algae, etc., can solve the problems of unstable separation culture method and low yield of desert green algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the industrialized cultivation method of this high-protein desert green algae is carried out according to the following steps: the first step, separates, and takes desert soil sample, adds the TAP liquid culture medium of 200ml to 400ml in every 50g to 100g desert soil sample According to the method, TAP liquid medium was added to the desert soil sample, and the shaker was shaken for 5min to 15min at a speed of 100rpm to 120rpm to fully mix the sample with the medium. Cultivate under the condition of 2000Lux to 3000Lux for 3 days to 15 days. After the culture supernatant turns green, apply every 200μL to 300μL supernatant on 25ml to 30ml TAP solid medium, and draw the supernatant under sterile conditions solution, coated in a petri dish containing TAP solid medium, and cultured for 3 to 15 days at a temperature of 25°C to 31°C and a light of 2000Lux to 3000Lux to obtain a culture of desert green algae;

[0021] In the second step, purification, each si...

Embodiment 2

[0023] Embodiment 2, the industrialized cultivation method of this high-protein desert green algae is carried out according to the following steps: the first step, separates, and takes desert soil sample, adds the TAP liquid culture medium of 200ml or 400ml in every 50g or 100g desert soil sample Add TAP liquid medium to the desert soil sample, and shake it with a shaker for 5min or 15min at a speed of 100rpm or 120rpm to fully mix the sample with the medium. Cultivate at 2000Lux or 3000Lux for 3 days or 15 days. After the culture supernatant turns green, apply every 200μL or 300μL of supernatant to 25ml or 30ml of TAP solid medium, and draw the supernatant under sterile conditions solution, coated in a petri dish containing TAP solid medium, and cultured for 3 days or 15 days at a temperature of 25°C or 31°C and a light of 2000Lux or 3000Lux to obtain a culture of desert green algae;

[0024] In the second step, purification, each single desert green algae colony is inocu...

Embodiment 3

[0026] Embodiment 3, preferably as above-mentioned embodiment, TAP liquid culture medium is 0.4gNH 4 Cl, 0.156gMgSO 4 , 0.05gCaCl 2 ·H 2 O, 0.142gK 2 HPO·3H 2 O, 2.42g TrisBase, 1.5ml HCl, 1.0ml glacial acetic acid, 2gCH 3 COONa·3H 2 O and 1 ml of trace elements are dissolved in water to prepare 1 L of solution to obtain a TAP liquid medium, and the pH range of the TAP liquid medium is 6.8 to 7.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com