Reinforced cement board containing glass fiber in three-dimensional net-shaped structure

A glass fiber mesh and glass fiber technology, applied in building materials and other directions, can solve the problems of complex production process and restrict the development of cement boards, and achieve the effect of high economic benefits, reducing equipment types, and improving technical indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

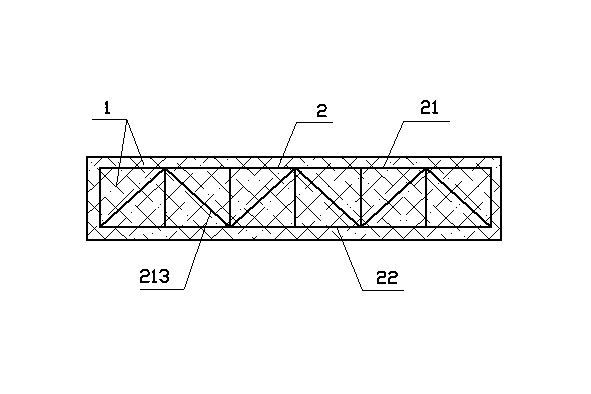

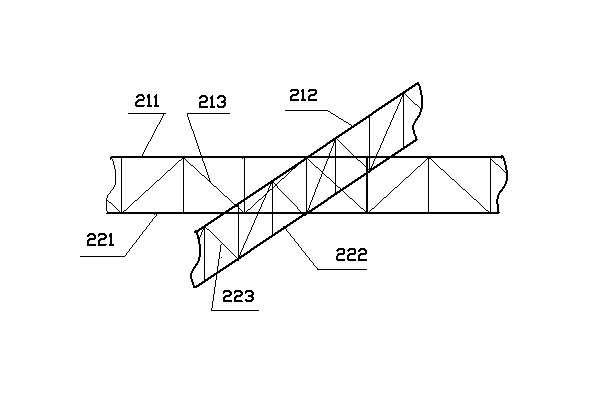

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: figure 1 It is a schematic cross-sectional view of the lateral structure of an embodiment of the present invention. In the figure, a reinforced cement board containing glass fibers in a three-dimensional network structure includes: a solidified layer 1 after uniform mixing of cement paste and glass fiber chopped strands, and a glass fiber frame 2 in a three-dimensional network structure; Described glass fiber frame is made up of upper plane glass fiber net 21, lower plane glass fiber net 22, some longitudinal glass fiber bundles 213, weft vertical glass fiber bundles 223, and upper glass fiber net 21 is composed of several warp threads 211, weft threads 212 are woven with each other at a certain interval to form a node-type grid. Similarly, the lower glass fiber net 22 is to be woven with each other at a certain interval by several warps 221 and wefts 222 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com