Straightening system and method for hydraulic support in coal mine working face

A technology of hydraulic support and working face, which is applied to mine roof support, mining equipment, earthwork drilling, etc., can solve the straightness deviation of hydraulic support and scraper conveyor, the influence of normal excavation work of working face, and the accumulation of sensor error of control system, etc. problem, to achieve the effect of improving reliability, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

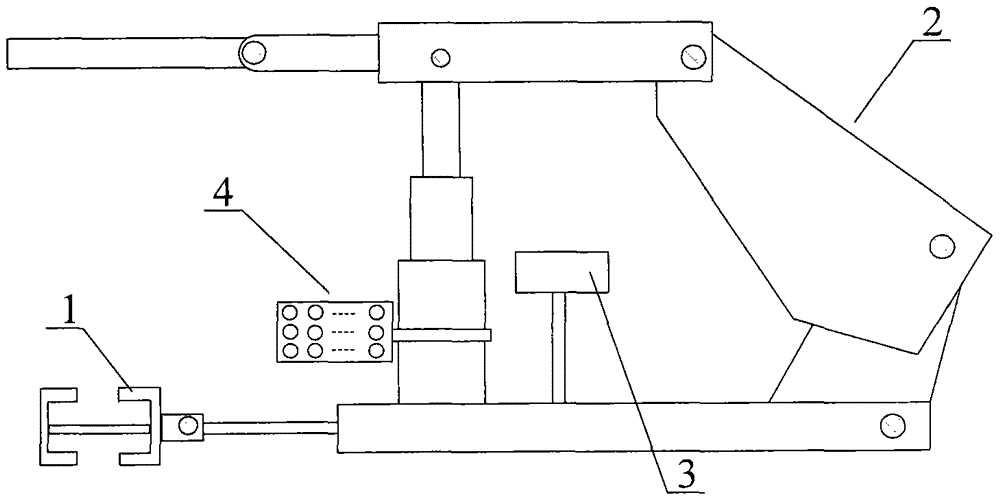

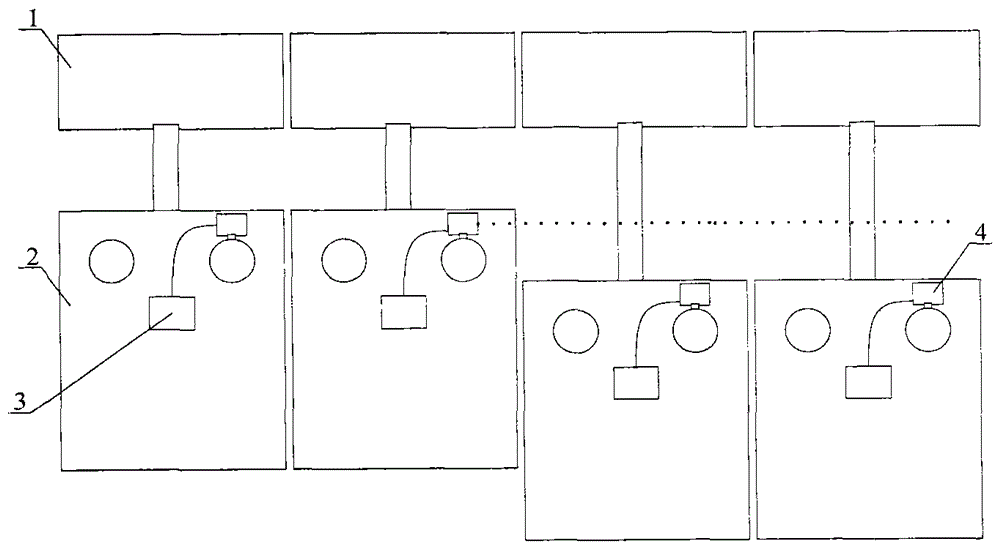

[0020] See attached Figure 1-2 , which describes a preferred embodiment of the coal mine working face hydraulic support straightening system according to the present invention. In this embodiment, as the working face is gradually advanced, each hydraulic support pushes the front scraper conveyor to move forward sequentially . A support controller and a laser transceiver are installed on the hydraulic support. The support controller performs basic operations such as the movement of the support, and can communicate with other support controllers to send and receive data information. The support controller and the laser transceiver Through the connector connection, the bracket controller can control the laser transceiver to receive and send signals. The laser transceiver is installed on the hydraulic support column. In order to prevent the laser transceiver from falling off and ensure the clear and stable laser signal, the laser transceiver is preferably connected to the steel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com