Manufacturing method of breakable launcher back cover of weapon system

A technology of a weapon system and a manufacturing method, applied in the direction of a launching device, etc., can solve the problems of the fragile rear cover of the launching tube, the fragments of the rear cover scattered on the ground behind the launching tube, etc. clean floor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in combination with specific embodiments.

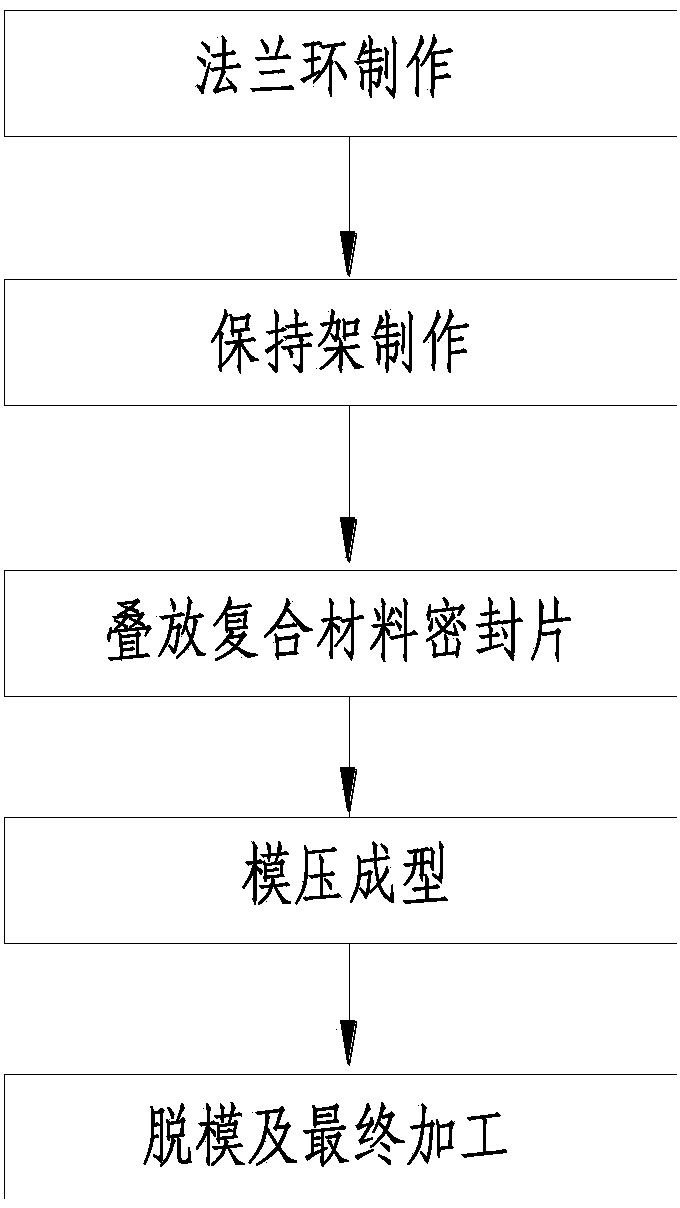

[0051] see together Figure 1-15 , a method for manufacturing a fragile rear cover of a weapon system launching tube, the steps comprising:

[0052] The first step, flange ring production:

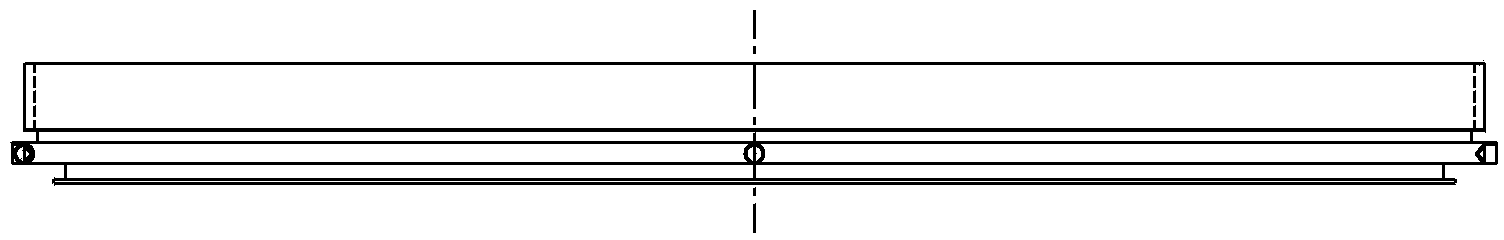

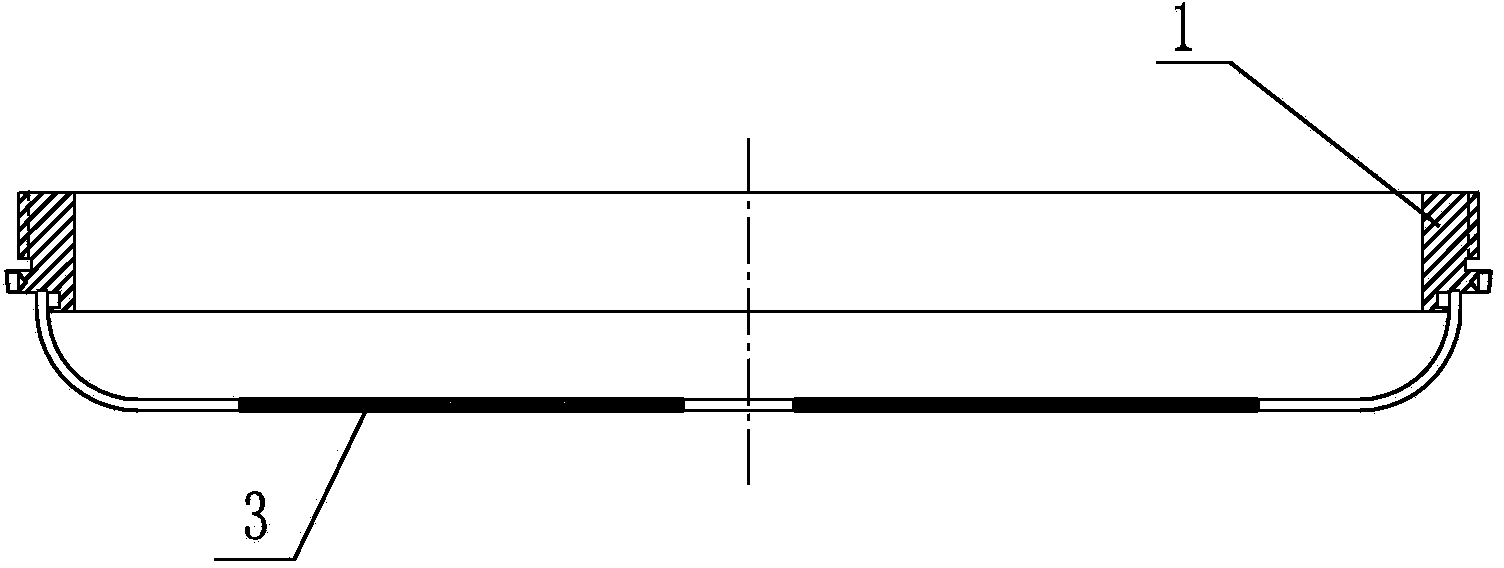

[0053] Machining a circular flange ring 1 with a height of 2-8cm and a diameter of 14-19cm; the outer side of one end of the flange ring 1 is processed and installed with an external thread 1a; the flange ring 1 A number of sockets 1b for inserting wrench rods are processed on the outside of the shell, which is convenient for fastening the flange on the launch tube. The flange ring 1 is also provided with a rubber sealing ring installation groove.

[0054] The second step, making the cage:

[0055] On the circumference of the other end of the flange ring 1, several tie-down pieces 3a are welded evenly at intervals. The tie-down piece 3a is a metal plate in the shape of a shovel. Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com