Rolling bearing stiffness testing experiment device and experiment method thereof

A technology of rolling bearing and testing experiment, applied in the direction of mechanical bearing testing, etc., to achieve the effect of easy disassembly, reliable use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

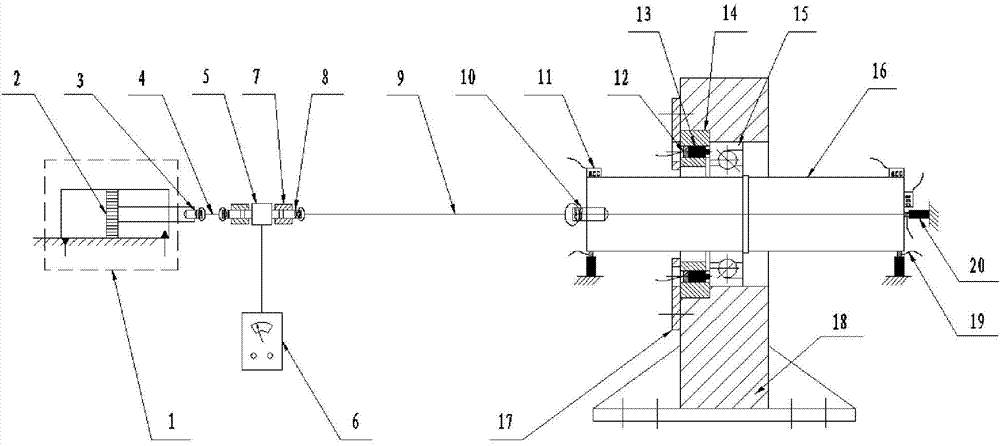

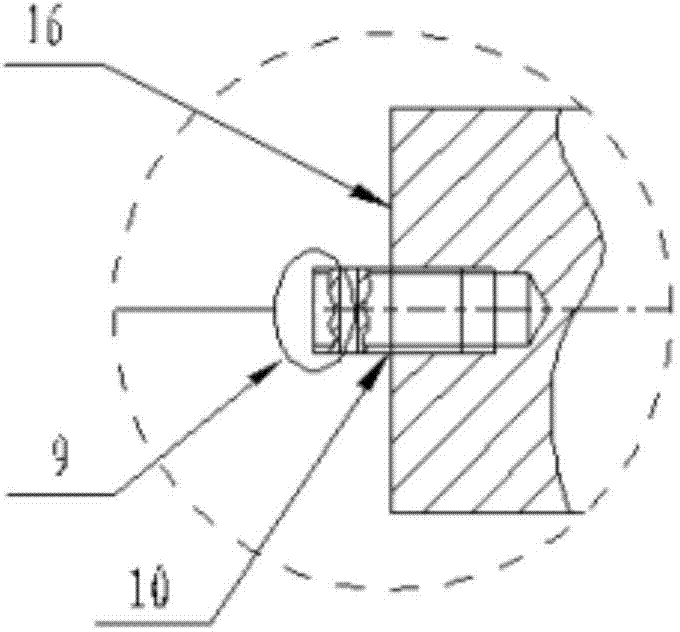

[0035] see Figure 1 to Figure 7 As shown, an experimental device for testing rolling bearing stiffness in the present invention includes a hydraulic initial preload module, a piezoelectric actuator preload adjustment module and a frequency response function test module.

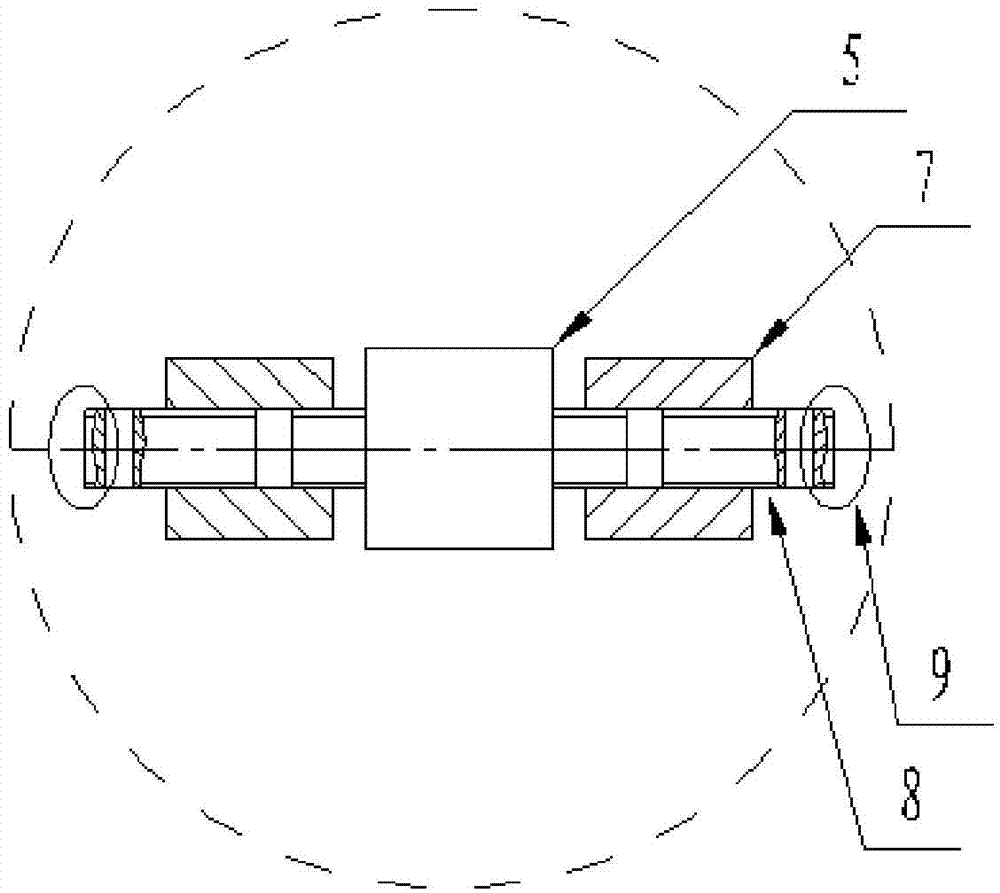

[0036] The hydraulic initial pretension module includes a hydraulic system 1, a hydraulic cylinder 2, a tension sensor 5, a tension indicator 6 and a main shaft 16; wherein, the hydraulic cylinder 2 is fixed on the experimental platform; the piston rod of the hydraulic cylinder 2 passes through the first screw with a pin hole in sequence 3. The first steel wire 4, the second screw with a pin hole, and the nut are connected to the left side of the tension sensor 5; the right side of the tension sensor 5 passes through the nut 7, the second screw with a pin hole 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com