Networking communication method of on-line wind turbine generator gearbox oil liquid monitoring system

A technology of gearbox oil and wind turbines, which is applied in the field of monitoring, can solve problems such as cost and power consumption, and achieve the effects of strong self-healing ability, low communication power consumption, and flexible networking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

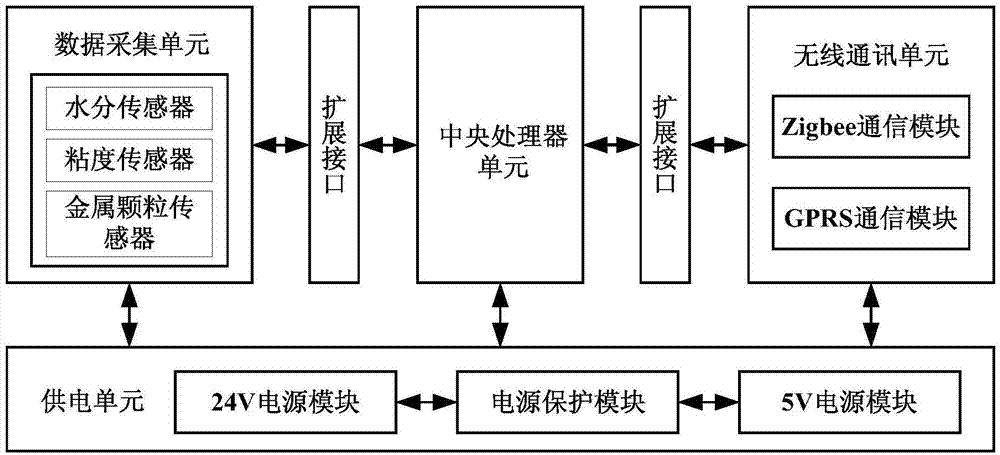

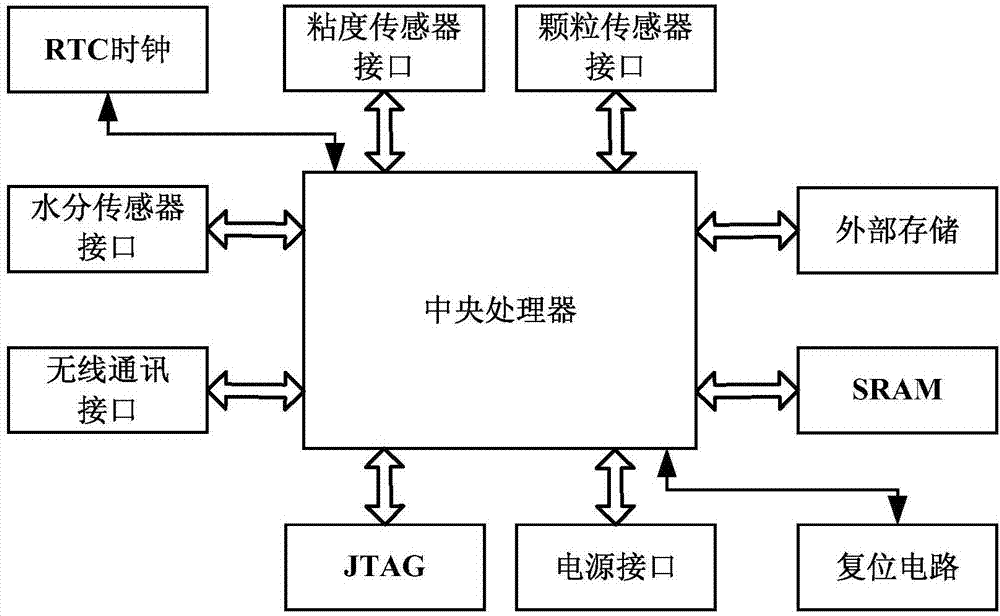

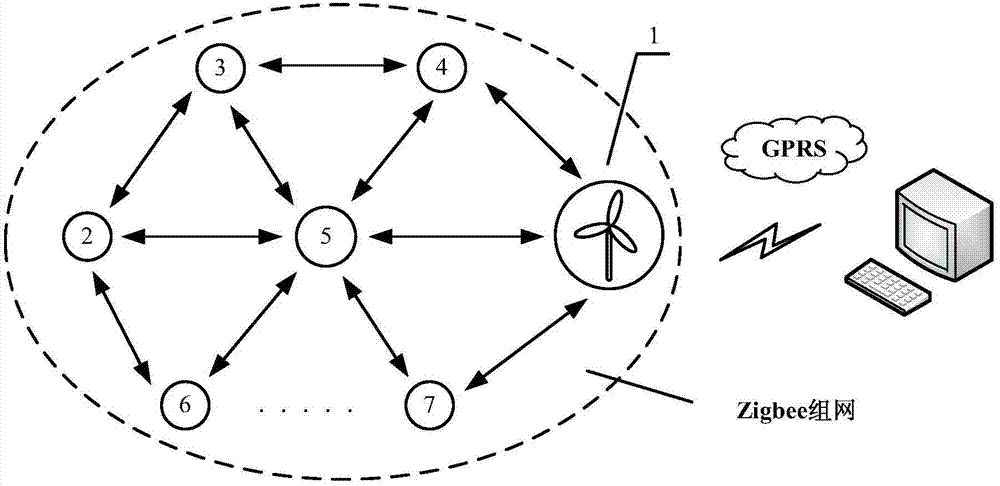

[0019] The network communication method of the wind turbine gearbox oil online monitoring system of the present invention is characterized in that the wind turbine gearbox oil online monitoring system is equipped with a central processing unit, a wireless communication unit, a power supply unit and a data acquisition unit. The central processing unit collects the moisture, metal particles and oil viscosity data detected by the front-end sensor through the data acquisition unit, and uses the Zigbee wireless communication module and GPRS wireless communication module of the wireless communication unit to transmit the data packets to the remote, so as to realize the oil quality information. Online Monitoring.

[0020] Below in conjunction with accompanying drawing, technical solution of the present invention is described in further detail:

[0021] Refer to attached figure 1 , The on-line oil monitoring system for the wind turbine gear box of the present invention is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com