Micron grating accelerometer testing method based on added mass

An accelerometer and additional mass technology, applied in the direction of speed/acceleration/shock measurement, test/calibration of speed/acceleration/shock measurement equipment, measurement device, etc. Problems such as rotational stability, complex structure and test methods, etc., can improve the test environment, shorten the development time, and improve the test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

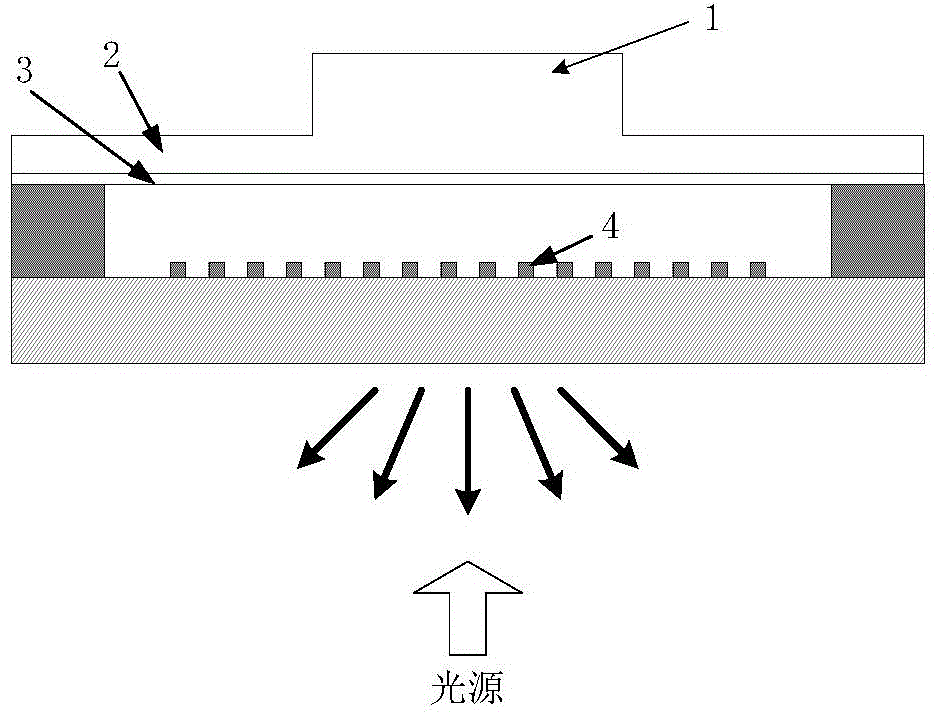

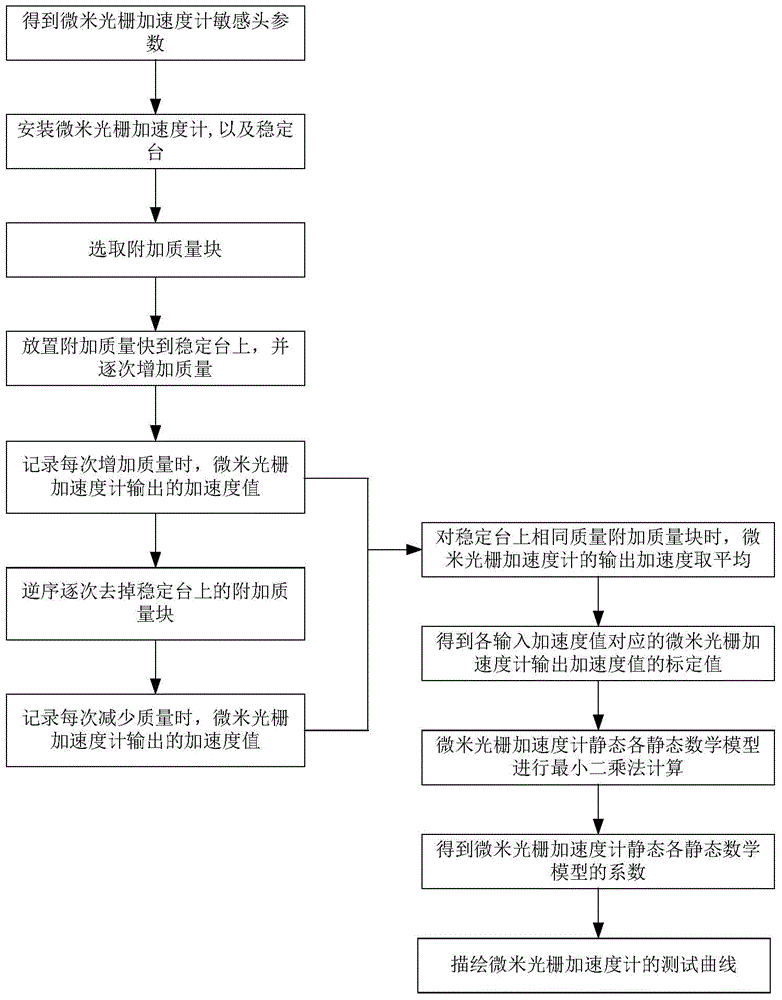

[0031] A kind of micron grating accelerometer testing method based on additional quality of the present invention, such as image 3 As shown, it is realized through the following steps:

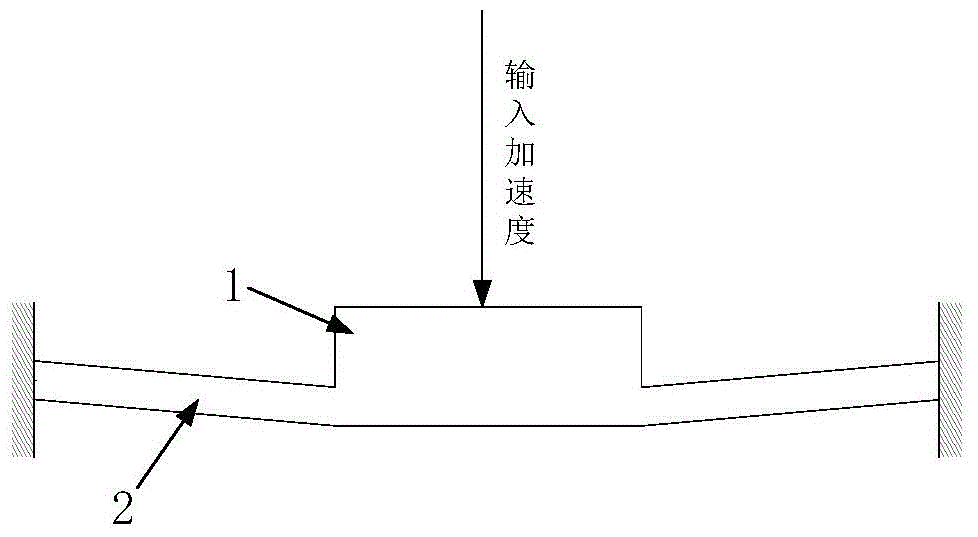

[0032] Step 1: Through theoretical calculation and simulation analysis, obtain the detectable input acceleration range of the micron grating accelerometer sensitive head, the elastic coefficient of the cantilever beam, the damping and the mass of the central mass and other sensitive head parameters.

[0033] Step 2: Install the sensitive head of the micron grating accelerometer on the test table, and at the same time install the stable platform on the central mass of the micron grating accelerometer, such as Figure 4 shown. In the present invention, guide holes are evenly opened in the circumferential direction of the stabilizing platform, and guide posts are inserted into the guiding holes as guide rails for the stabilizing platform to move up and down, so that the stabilizing platform onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com