Megohmmeter Simulation Verification Method

A megohmmeter and simulation technology, which is applied in the field of megohmmeter verification, can solve the problems of difficult equipment calibration or optimal design, large investment, high price, etc., and achieve the effect of reducing test safety risks, avoiding investment, and avoiding instrument damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

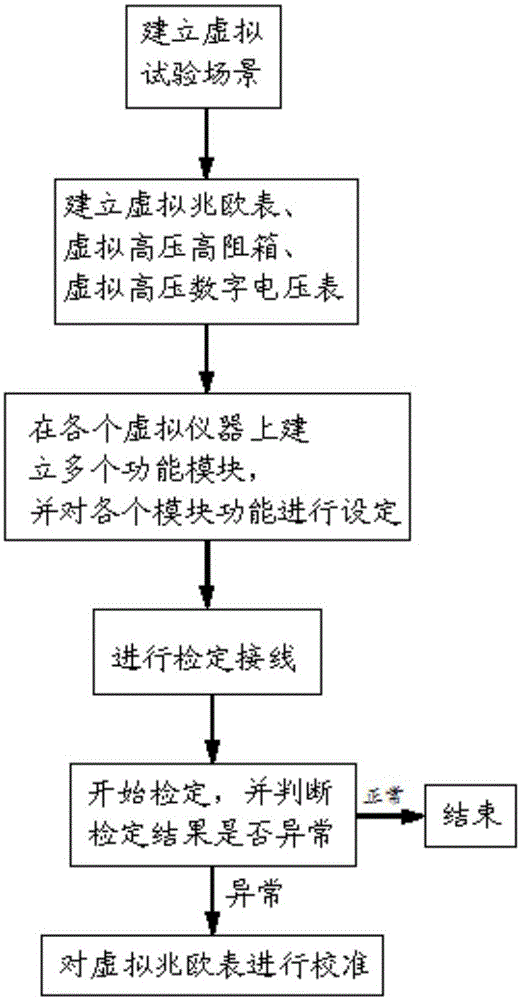

[0046] Such as figure 1 As shown, in an embodiment of the present invention, a megohmmeter simulation verification method includes the following steps:

[0047] a. Create a virtual test scene;

[0048] b. Establish a virtual megohmmeter, a virtual high-voltage high-resistance box and / or a virtual high-voltage digital voltmeter in the virtual test scene, and respectively establish a virtual megohmmeter, a virtual high-voltage high-resistance box and / or a virtual high-voltage digital voltmeter Multiple functional modules, initialize the functions of each functional module, and set the response area of each functional module;

[0049] c. Verification wiring of virtual megohmmeter, virtual high-voltage high-resistance box and / or virtual high-voltage digital voltmeter;

[0050] d. Establish the measured value normal state table and the measured value abnormal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com