Shaft having a journal

A bearing and longitudinal axis technology, used in rigid shaft couplings, couplings, elastic couplings, etc., can solve problems such as increasing wear, hindering the purpose of use, and deteriorating efficiency, and achieves high efficiency and reduced wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

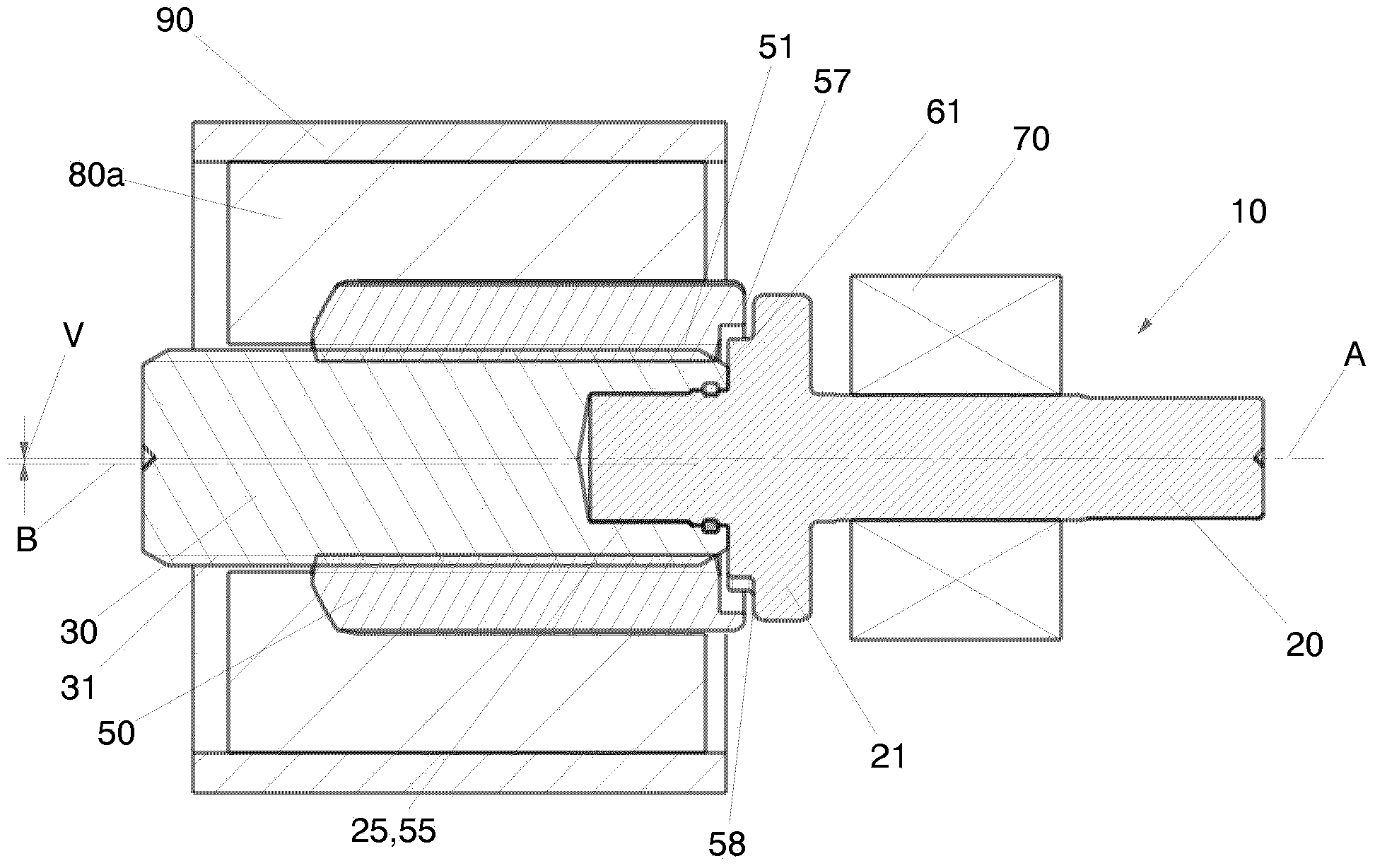

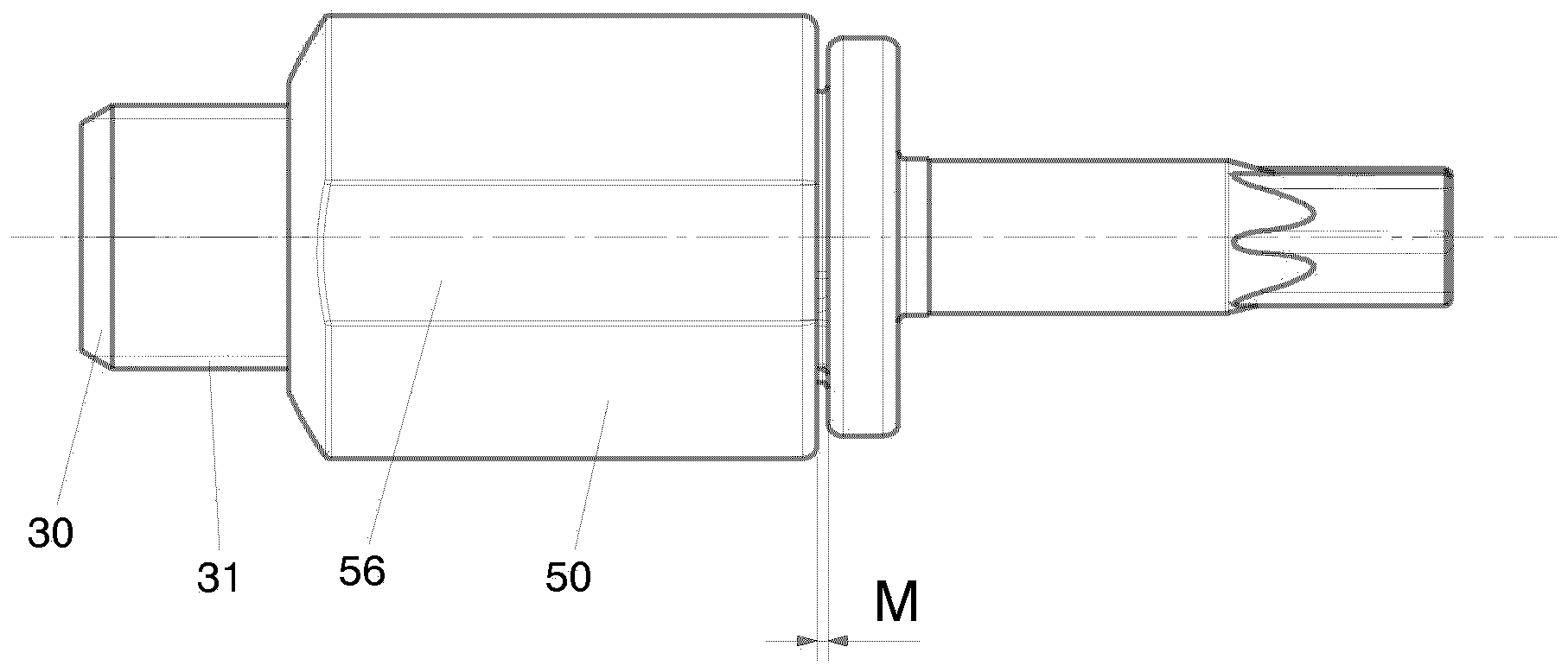

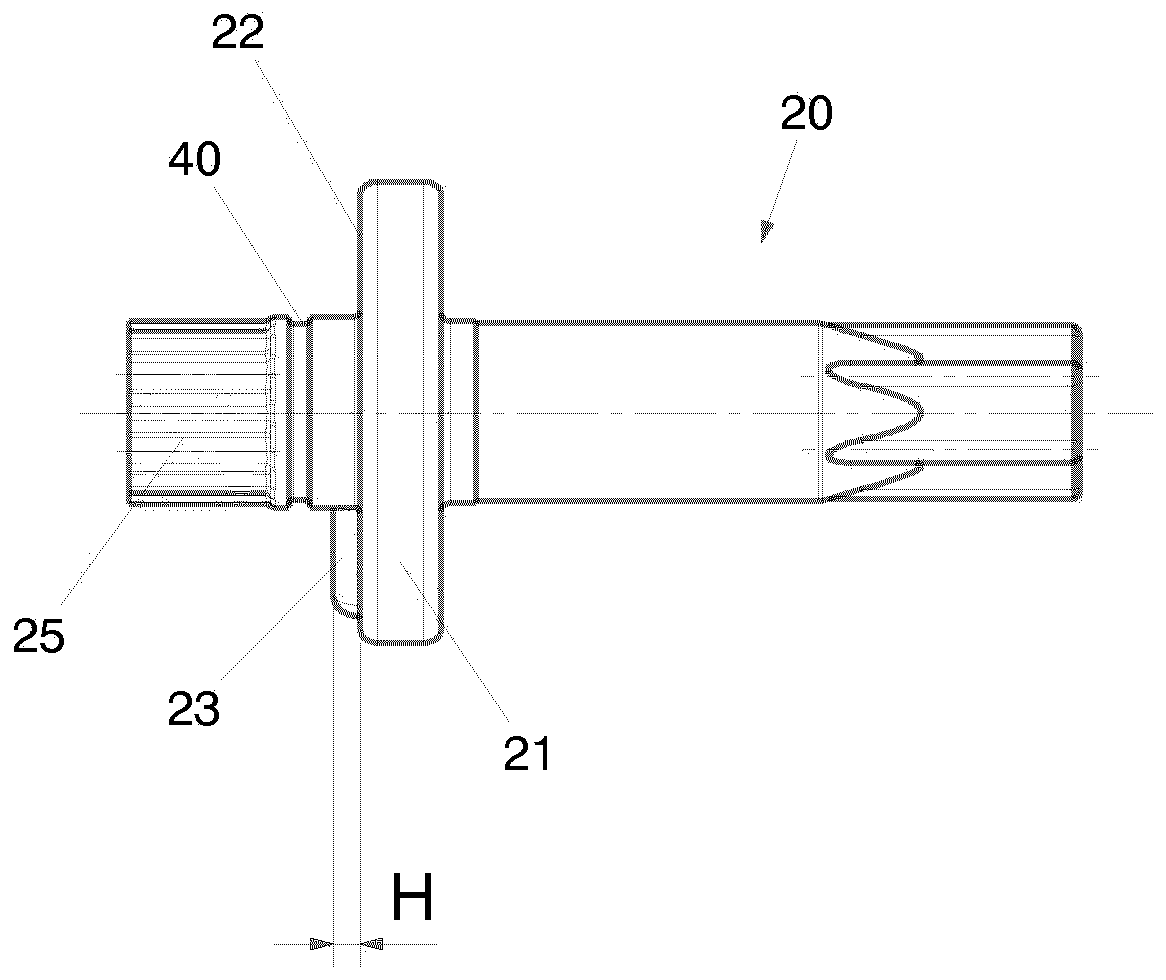

[0042] figure 1 Shown is a longitudinal sectional view of a first embodiment of a threaded spindle according to the invention, generally designated 10 . The lead screw 10 comprises: a drive portion 20 having a longitudinal axis A and supported by a first bearing 70; and a threaded portion 30 having a longitudinal axis B; and a nut 50 supported by a second bearing 80a and The threaded portion 30 is guided in this nut. There are at least two embodiments for the second bearing, figure 1 A first embodiment of which is shown and marked 80a while Figure 17 A second embodiment is shown and designated 80b. according to figure 1 As shown in the figure, the threaded part 30 and the nut 50 have threads 31 or 51 respectively, and these threads mesh with each other. The thread 31 is an external thread, and the thread 51 is an internal thread. The driving part 20 and the threaded part 30 are constructed as separate parts, which are respectively provided with engagement elements 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com