Zirconia ceramic material applied to dental restoration and preparation method of zirconia ceramic material

A zirconia ceramic and dental technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of poor biocompatibility, unfavorable promotion of production and use, etc., and achieve good anti-effect performance, excellent mechanical properties, biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

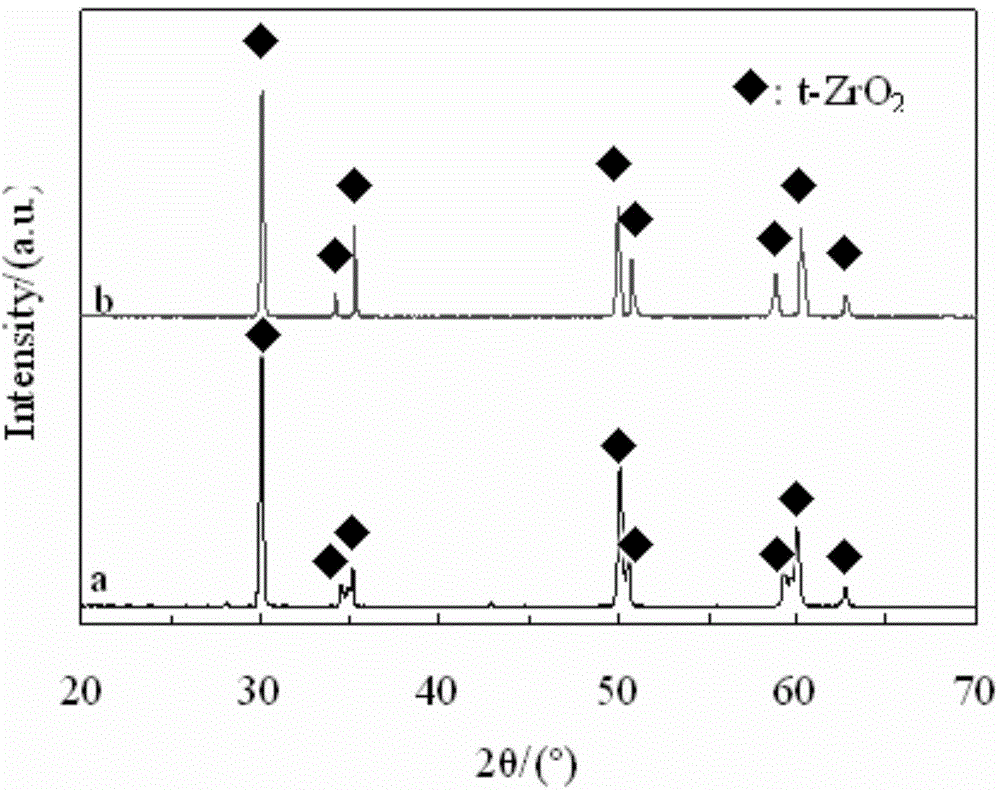

[0025] The zirconia ceramic material used for dental restoration in this embodiment consists of the following molar percentages: Nb 2 o 5 1.5%, SnO 2 4%, ZrO 2 94.5%.

[0026] The preparation method of the zirconia ceramic material for dental restoration in this embodiment:

[0027] Step one, the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The powder is added into the ball mill according to the molar percentage, and the ball mill is mixed evenly, and then the undersize is taken through a 300 sieve to obtain the mixed powder; the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The average particle size of the powder is not greater than 5 μm, and the mass purity is not less than 99.95%.

[0028] Step 2. Perform cold isostatic pressing of the mixed powder described in step 1 to obtain a powder compact; the pressure of the cold isostatic pressing is 300 MPa, and the time of the cold isostatic pressing is 2 minutes;

[0029] Step 3. Put the powder compact described in step 2 into a...

Embodiment 2

[0035] The zirconia ceramic material used for dental restoration in this embodiment consists of the following molar percentages: Nb 2 o 5 3%, SnO 2 1.5%, ZrO 2 95.5%.

[0036] The preparation method of the zirconia ceramic material for dental restoration in this embodiment:

[0037] Step one, the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The powder is added into the ball mill according to the molar percentage, and the ball mill is mixed evenly, and then the undersize is taken through a 300 sieve to obtain the mixed powder; the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The average particle size of the powder is not greater than 5 μm, and the mass purity is not less than 99.95%.

[0038] Step 2. Carrying out cold isostatic pressing of the mixed powder described in step 1 to obtain a powder compact; the pressure of the cold isostatic pressing is 350 MPa, and the time of the cold isostatic pressing is 2 minutes;

[0039] Step 3. Put the powder compact described in step 2 i...

Embodiment 3

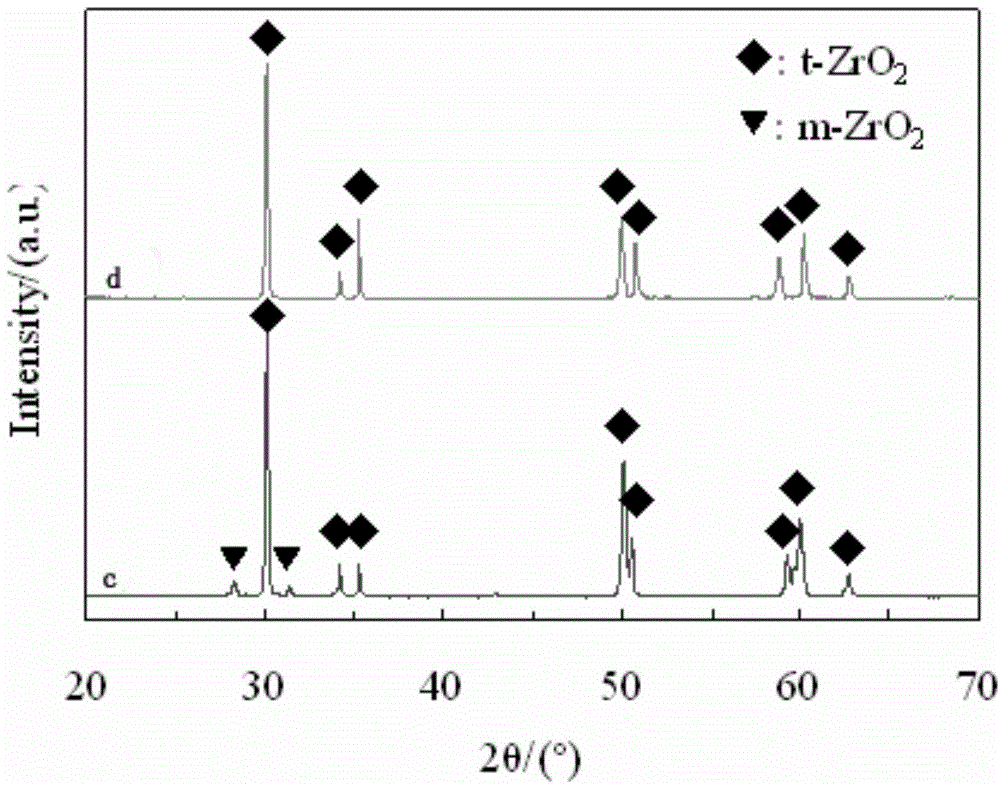

[0043] The zirconia ceramic material used for dental restoration in this embodiment consists of the following molar percentages: Nb 2 o 5 4%, SnO 2 1.5%, ZrO 2 94.5%.

[0044] The preparation method of the zirconia ceramic material for dental restoration in this embodiment:

[0045] Step one, the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The powder is added into the ball mill according to the molar percentage, and the ball mill is mixed evenly, and then the undersize is taken through a 300 sieve to obtain the mixed powder; the Nb 2 o 5 Powder, SnO 2 Powder and ZrO 2 The average particle size of the powder is not greater than 5 μm, and the mass purity is not less than 99.95%.

[0046] Step 2. Carrying out cold isostatic pressing of the mixed powder described in step 1 to obtain a powder compact; the pressure of the cold isostatic pressing is 250 MPa, and the time of the cold isostatic pressing is 5 minutes;

[0047] Step 3: Put the powder compact described in step 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com