Processing system and construction method capable of improving fineness modulus of natural sand

A fineness modulus and processing system technology, applied in chemical instruments and methods, solid separation, filtration and sieving, etc., can solve the problem of excessive fine aggregate, insufficient sand content of natural sand, natural sand gradation and demand can not meet the construction Requirements and other issues to achieve the effect of improving output and production quality and reducing operating costs

Inactive Publication Date: 2014-02-05

CHINA GEZHOUBA GROUP NO 5 ENG

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Restricted by natural conditions, the natural sand and gravel materials in some natural riverbeds of inland rivers contain too much fine aggregate, the sand content of natural sand is insufficient, and the fineness modulus of sand is less than 2.0. The natural sand gradation and demand for direct screening and washing are based on Cannot meet construction requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

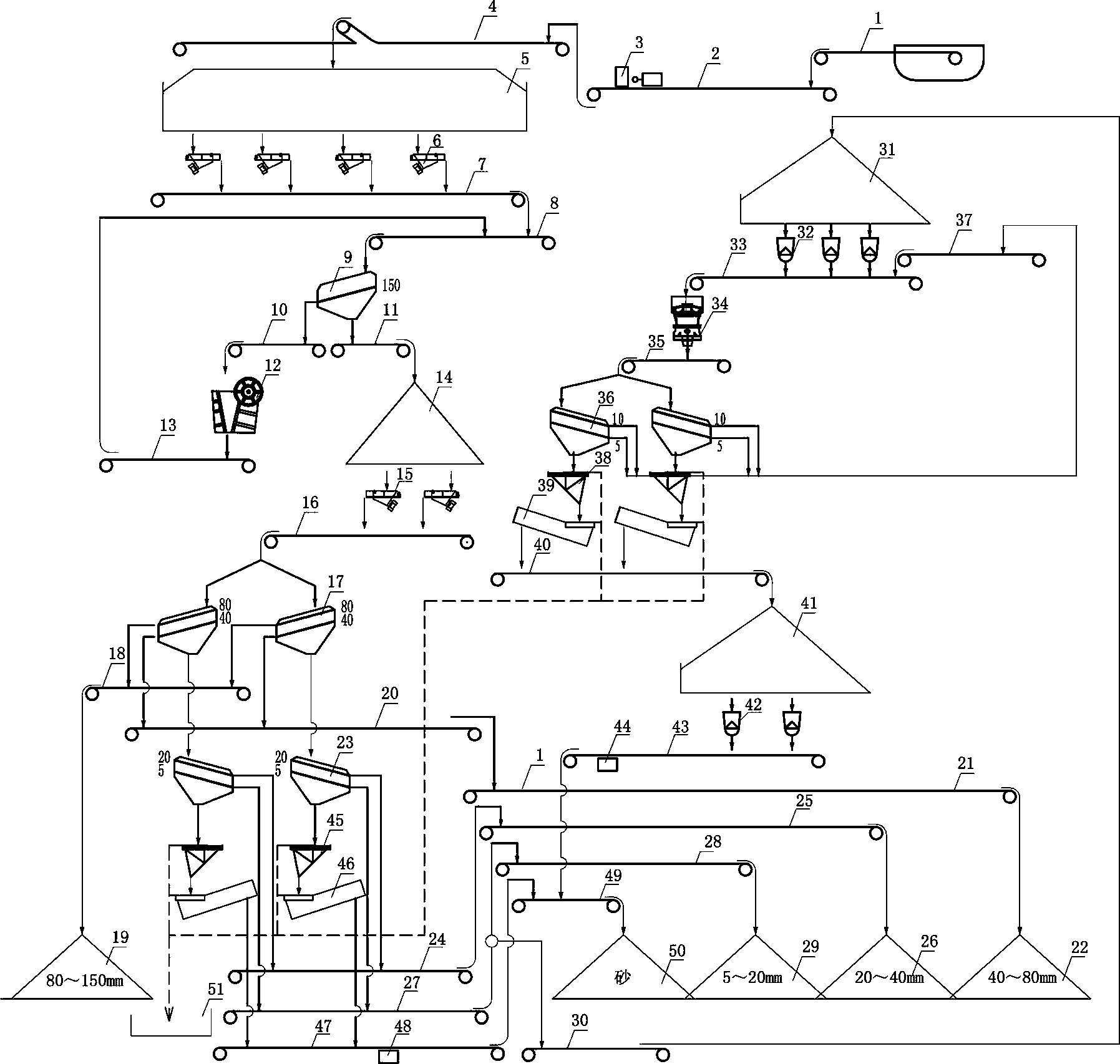

The invention discloses a processing system and a construction method capable of improving the fineness modulus of natural sand. The advantage of high fine aggregate content of a natural river bed is fully utilized, and a vertical-axis impact crusher is selected to process small stones into artificial sand with high fineness modulus, so that the shortcomings of low natural sand content and low fineness modulus are compensated and overcome, the yield and production quality of the sand are improved, and the running cost of the whole system is also lowered. The system and the method are particularly applied to the working conditions of low fineness modulus, low natural sand content and high fine aggregate content of natural grits mined underwater.

Description

technical field [0001] The invention belongs to a processing system and a construction method for improving the fineness modulus of natural sand, and is especially suitable for working conditions where the fineness modulus of natural sand and gravel materials in underwater mining is relatively small, and the content of natural sand is insufficient and the fine aggregate is too much . Background technique [0002] Fineness modulus is an important index to measure the quality of sand, which directly affects the workability, strength, impermeability and durability of concrete. The existing construction code requires the fineness modulus of sand to be 2.4 to 2.8. [0003] Restricted by natural conditions, the natural sand and gravel materials in some natural riverbeds of inland rivers contain too much fine aggregate, the sand content of natural sand is insufficient, and the fineness modulus of sand is less than 2.0. The natural sand gradation and demand for direct screening and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C21/00B02C23/00B07B1/28

Inventor 刘宏

Owner CHINA GEZHOUBA GROUP NO 5 ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com