Full-automatic bearing ring forging line

A technology for bearing rings and production lines, which is used in manufacturing tools, engine components, forging/pressing/hammer devices, etc., can solve the problems of difficult to guarantee the consistency of the quality of the wool, the work intensity of workers, and the poor quality of the wool. The effect of improving the quality of maoqi, reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

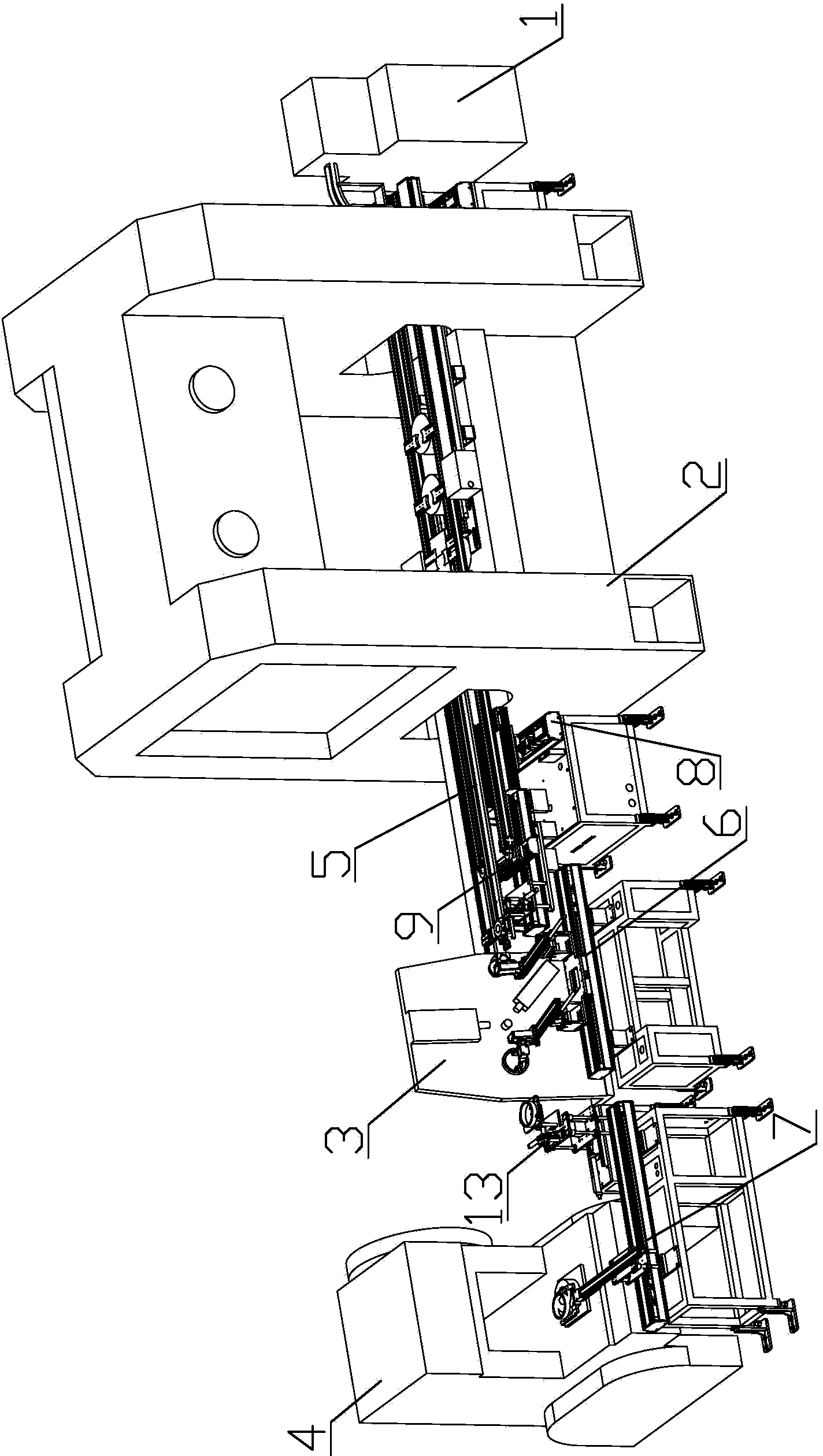

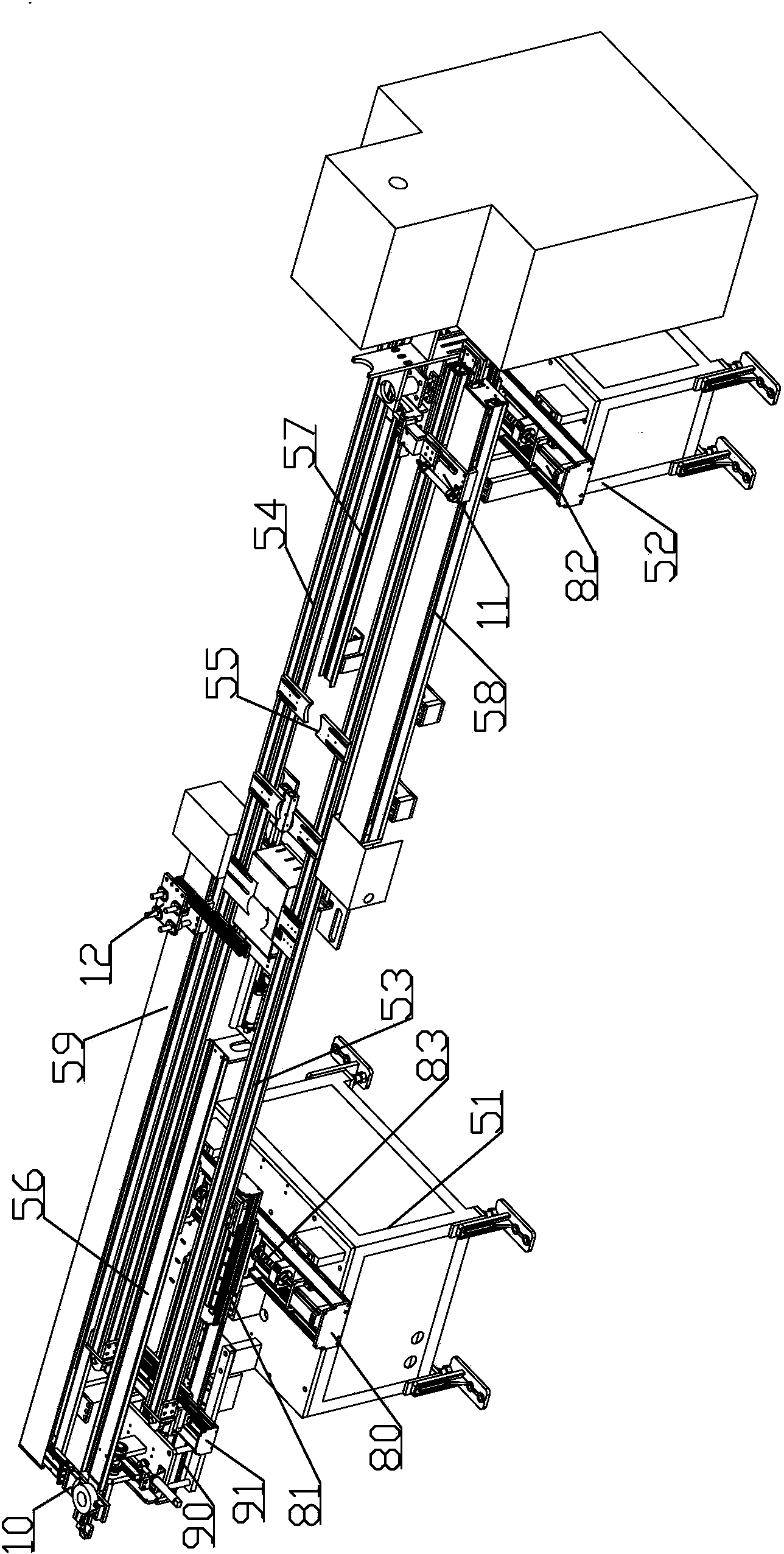

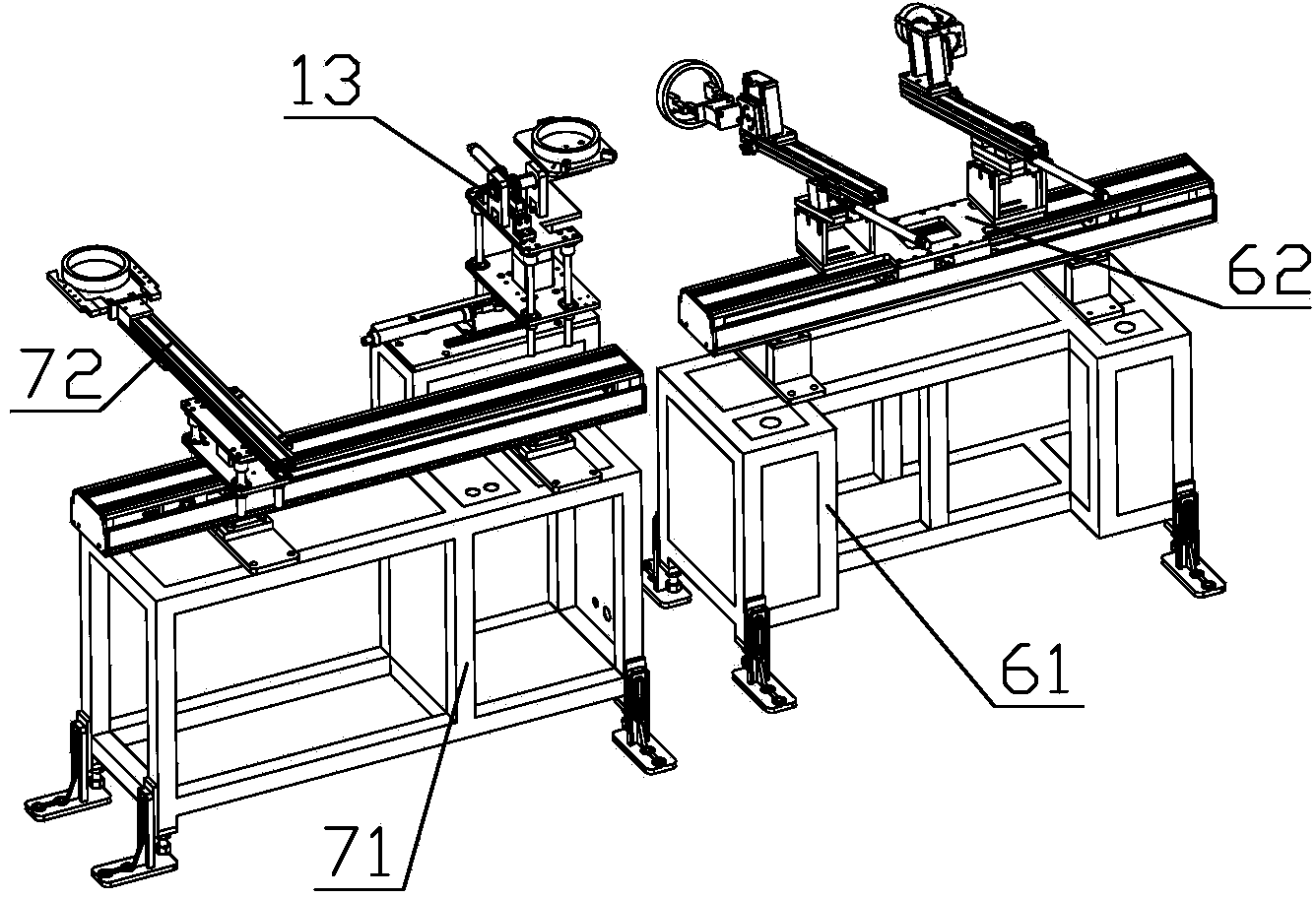

[0020] Such as figure 1 , figure 2 , image 3 As shown, the fully automatic bearing ring forging production line includes preheating furnace, shearing punch, heating furnace 1, pneumatic punch 2, rolling machine 3, shaping punch 4, stamping manipulator 5, rolling manipulator 6, shaping manipulator 7. The preheating furnace is a natural gas furnace, and the heating furnace 1 is a medium frequency induction heating furnace. The preheating furnace, cutting punch, heating furnace 1, pneumatic punch 2, rolling machine 3, and shaping punch 4 are arranged in a straight line. The stamping manipulator 5 includes a left frame 51, a right frame 52 arranged on the left and right sides of the pneumatic punch press 2, and a front clamping arm 53 and a rear clamping arm straddling the upper parts of the left frame 51 and the right frame 52. 54. The two clamp arms are provided with three pairs of clamp jaws 55, and the left and right ends of the two clamp arms are provided with clamp arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com