Aerator

An aerator and air bubble technology, applied in the field of aerator, can solve the problems of large exhaust resistance loss, easy blockage of pores, blockage of intake pipe, etc., and achieve the effect of stable operation and obvious non-return effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

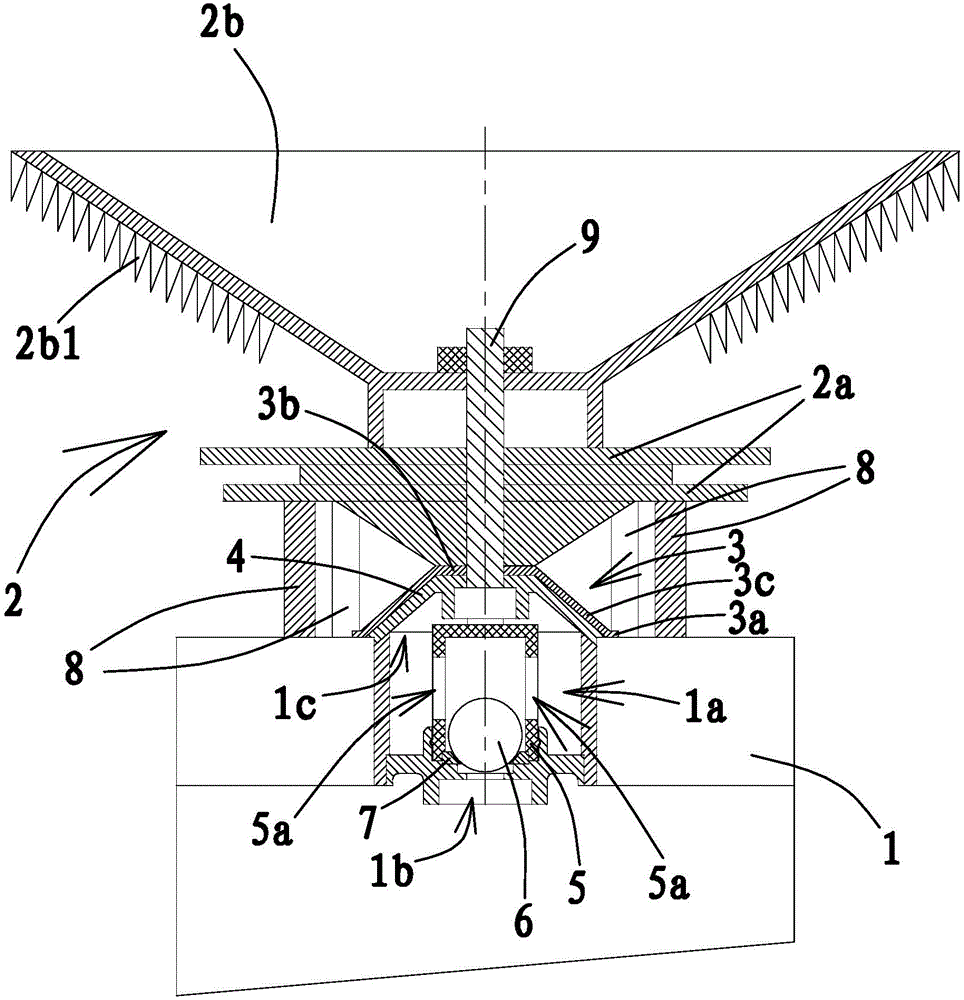

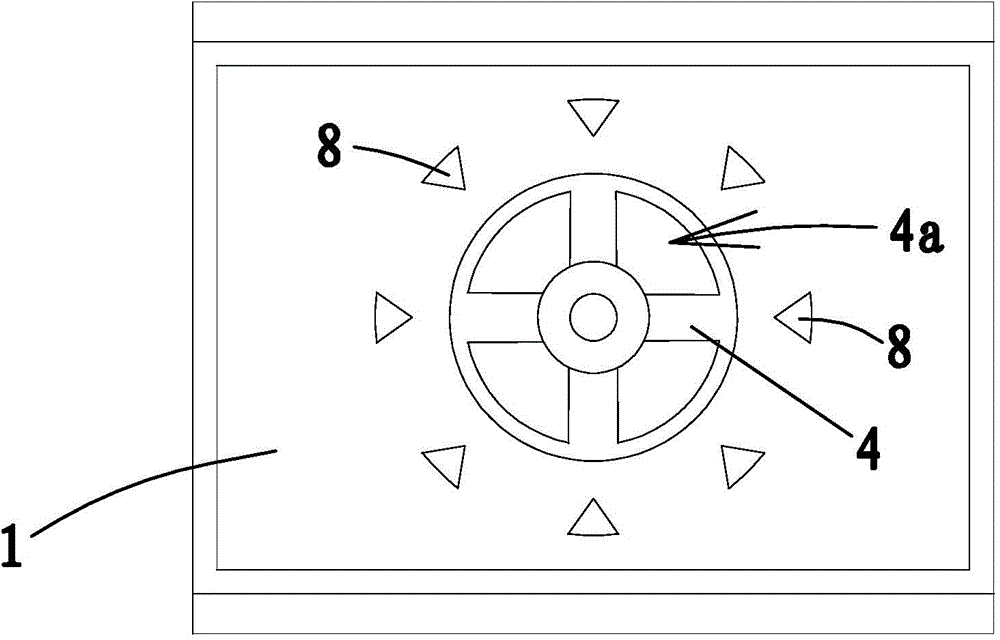

[0041] Such as figure 1 As shown, the aerator includes a mounting base body 1, the middle part of the mounting base body 1 has an air inlet cavity 1a, the upper end of the air intake cavity 1a has an air outlet 1c, and the lower end of the air intake cavity 1a has an air inlet 1b.

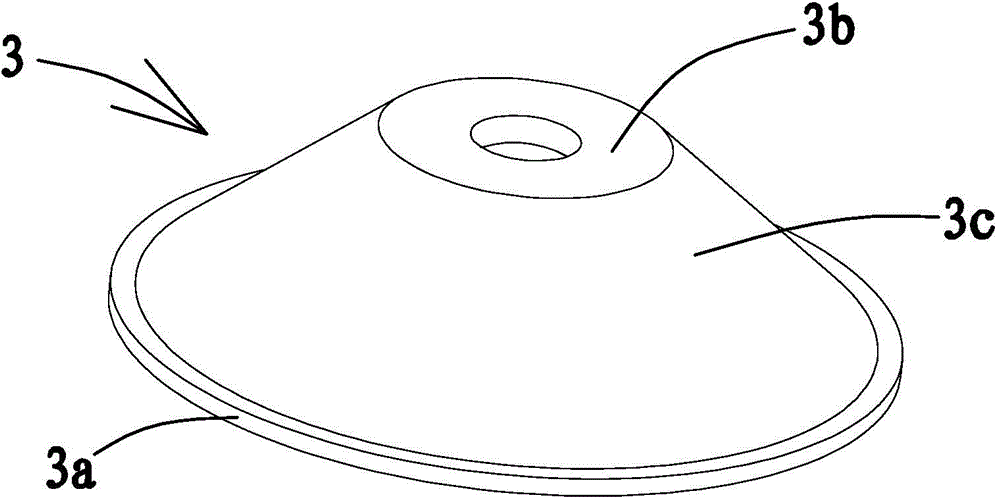

[0042] Such as figure 1 with Figure 4 As shown, the air intake cavity 1a is vertically provided with an air intake pipe 5, the air inlet 1b is located at the lower end of the air intake pipe 5, and the air intake pipe 5 is provided with a check ball 6. The upper end of air intake pipe 5 is blocked. Except for the air inlet 1b and the air outlet 1c in the air inlet pipe 5, other parts of the air inlet cavity are sealed from the outside world...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com