Poly-(phenylene vinylene)-phthalocyanine zinc polymer with optical limiting effect and its preparation method and application

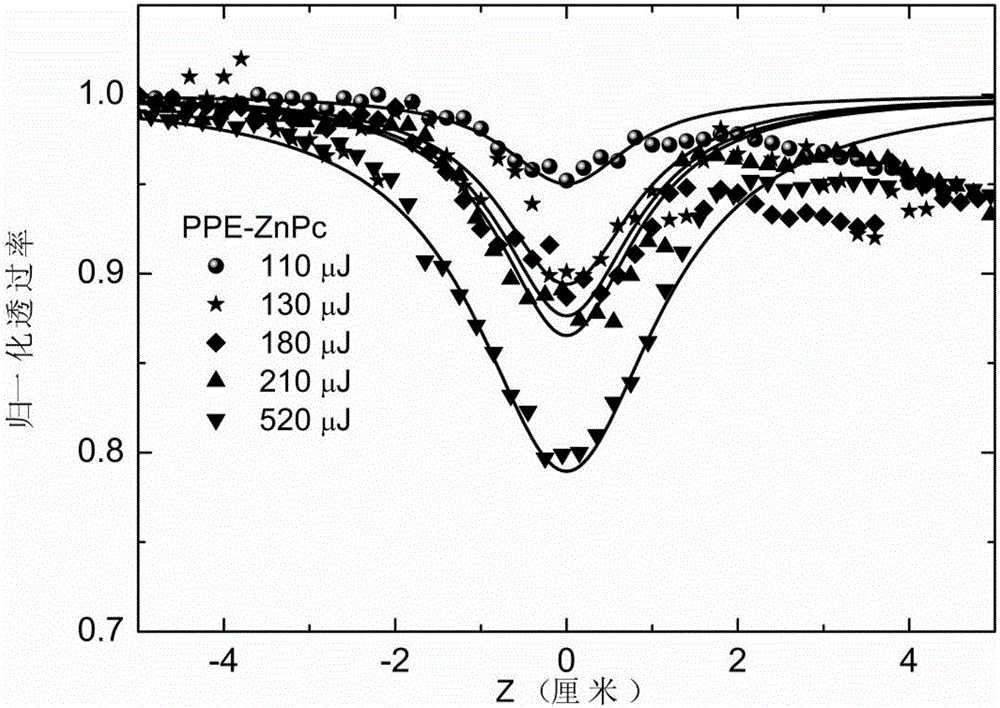

A polymer and phenylacetylene technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy phase separation and affect the optical limiting performance of the system, and achieve the effect of avoiding phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

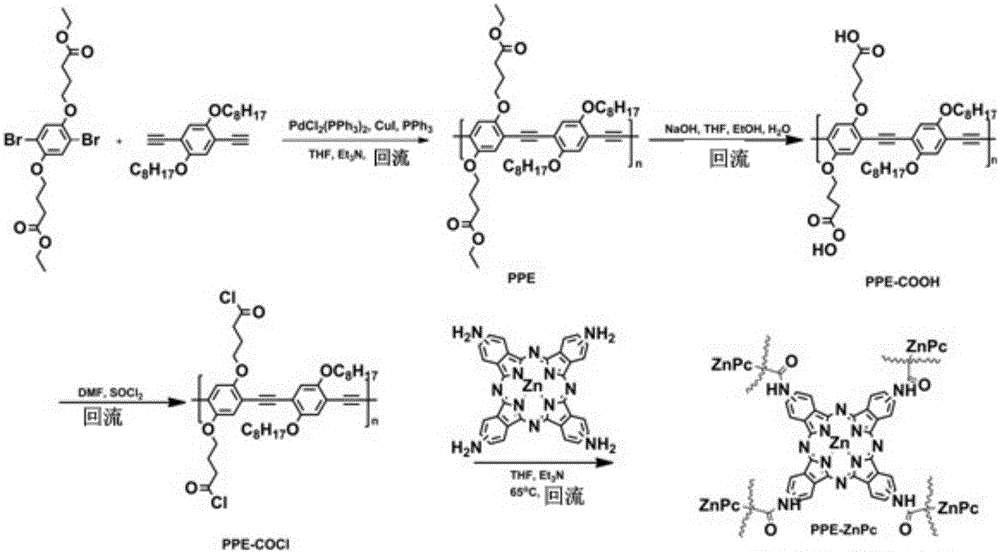

[0041] A: Preparation of polymer PPE: under nitrogen protection, compound 1,4-bis(oxy-butyric acid ethyl)-2,5-dibromobenzene (248.10 mg), 1,4-bis(octyloxy) -2,5-diethynylbenzene (191.25 mg) dissolved in THF (80 mL) and Et 3 N (80 ml) mixed solvent, sequentially add catalyst: 35.2 mg PdCl 2 (PPh 3 ) 2 , 9.6 mg CuI, 26.24 mg PPh3 , heated to reflux for reaction for 4 days, after the reaction was completed, the solvent was spin-dried to obtain a yellow solid, washed and filtered with 500 ml of water, the filter cake was washed with water, ethanol and acetone respectively, and dried to obtain PPE;

[0042] B: Preparation of polymer PPE-COOH: PPE (150 mg) was dissolved in THF (100 ml) and CH 3 CH 2 OH (100 milliliters) in the mixed solvent composition, add NaOH aqueous solution (5.6 gram NaOH is dissolved in 20 milliliters H 2 O), heated to reflux for 24 hours, poured into 500 milliliters of water after cooling, adjusted pH=1 with HCl, filtered the obtained yellow solid, and w...

Embodiment 2

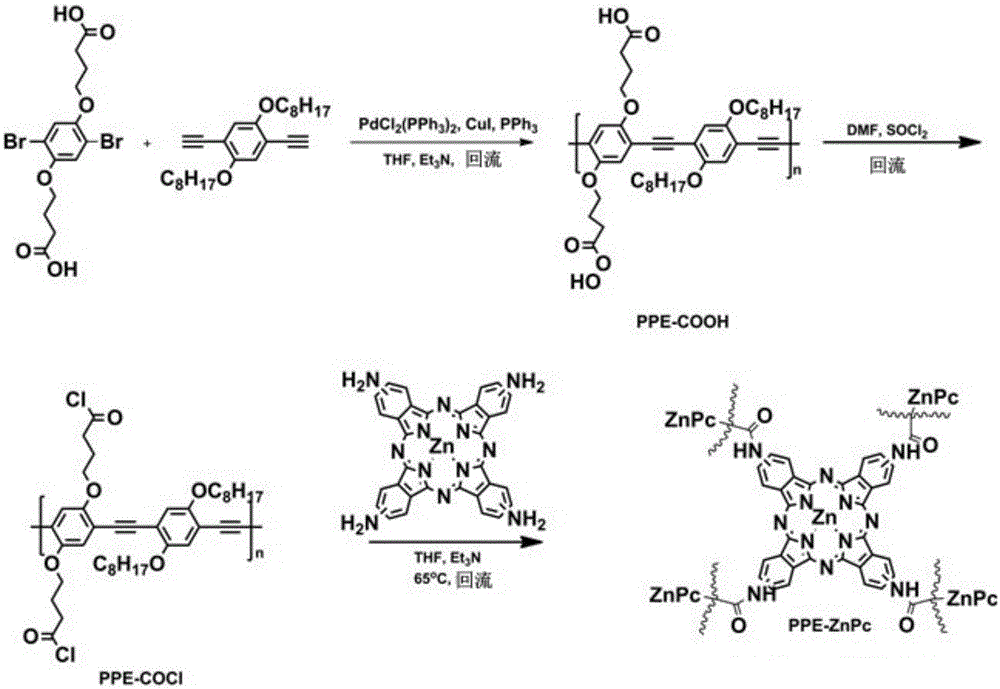

[0047] A: Preparation of polymer PPE-COOH: Under nitrogen protection, 220.04 mg of 1,4-bis(butyric acid oxy)-2,5-dibromobenzene, 191.25 mg of 1,4-bis(octyloxy)- 2,5-diethynylbenzene dissolved in 60 mL THF and 60 mL Et 3 In the mixed solvent of N, sequentially add the catalyst: 35.2 mg PdCl 2 (PPh 3 ) 2 , 9.6 mg CuI, 26.24 mg PPh 3 , heated to reflux for 4 days. After the reaction, the solvent was spin-dried to obtain a yellow solid, which was washed and filtered with 400 ml of water, and the filter cake was washed with water, ethanol, and acetone respectively, and dried to obtain a yellow solid PPE-COOH;

[0048] B: Preparation of polymer PPE-COCl: The dry polymer PPE-COOH (130 mg) was dissolved in 30 mL SOCl under nitrogen 2 , add 0.5 ml of DMF, heat to reflux, until the raw material PPE-COOH is completely dissolved in SOCl 2 When the reaction was over, the SOCl was removed under reduced pressure 2 , to obtain PPE-COCl;

[0049] C: Preparation of polymer PPE-ZnPc: Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com