Spray-free modified polypropylene material with paint brightness and silver metal texture

A polypropylene material and metal texture technology, applied in the field of polypropylene materials, can solve the problems of unsatisfactory paint gloss and metal texture, affecting the density of polypropylene, etc., to achieve good paint gloss and metal texture, similar appearance effect, and free of The effect of removing cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

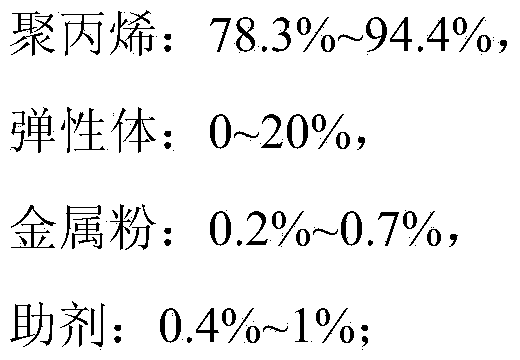

Method used

Image

Examples

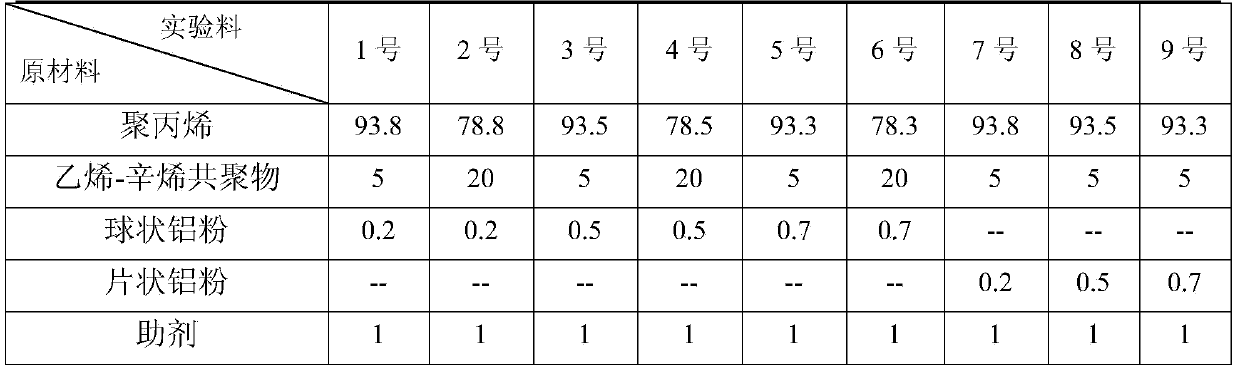

Embodiment 1

[0025] Weigh polypropylene (Rockwell hardness 90R-scale, melt index 40g / 10min, tensile strength 35Mpa), ethylene-octene copolymer, spherical aluminum powder (40 mesh) and additives (stearin Zinc acid, antioxidant 3114 and anti-ultraviolet agent are mixed in a mass ratio of 3:2:1), mixed uniformly in a high-speed mixer, and then the blend is kneaded in a twin-screw extruder. The temperature of each zone of the twin-screw extruder was controlled at 190-210°C, and the rotational speed of the twin-screw extruder was 600r / min; extruded and granulated, and the experimental material No. 1 was finally obtained.

Embodiment 2

[0027] Weigh polypropylene (Rockwell hardness 100R-scale, melt index 50g / 10min, tensile strength 45Mpa), ethylene-octene copolymer, spherical aluminum powder (40 mesh) and additives (stearic acid) according to the formula in Table 1. Zinc, antioxidant 3114 and anti-ultraviolet agent are mixed in a mass ratio of 3:2:1), mixed uniformly in a high-speed mixer, and then the blend is kneaded in a twin-screw extruder. The temperature of each zone of the twin-screw extruder was controlled at 190-210°C, and the rotational speed of the twin-screw extruder was 600r / min; extruded and granulated, and the experimental material No. 2 was finally obtained.

Embodiment 3

[0029] Weigh polypropylene (Rockwell hardness 100R-scale, melt index 50g / 10min, tensile strength 45Mpa), ethylene-octene copolymer, spherical aluminum powder (40 mesh) and additives (stearic acid) according to the formula in Table 1. Zinc, antioxidant 3114 and anti-ultraviolet agent are mixed in a mass ratio of 3:2:1), mixed uniformly in a high-speed mixer, and then the blend is kneaded in a twin-screw extruder. The temperature of each zone of the twin-screw extruder was controlled at 190-210°C, and the rotational speed of the twin-screw extruder was 600r / min; extruded and granulated, and finally experimental material No. 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com