Ribbed prestressed concrete plate type noise barrier unit plate

A concrete and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of PC boards such as poor bending fatigue resistance, heat sealing performance, poor UV resistance, and easy to blur when placed, so as to achieve light density and avoid fatigue Stress, the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

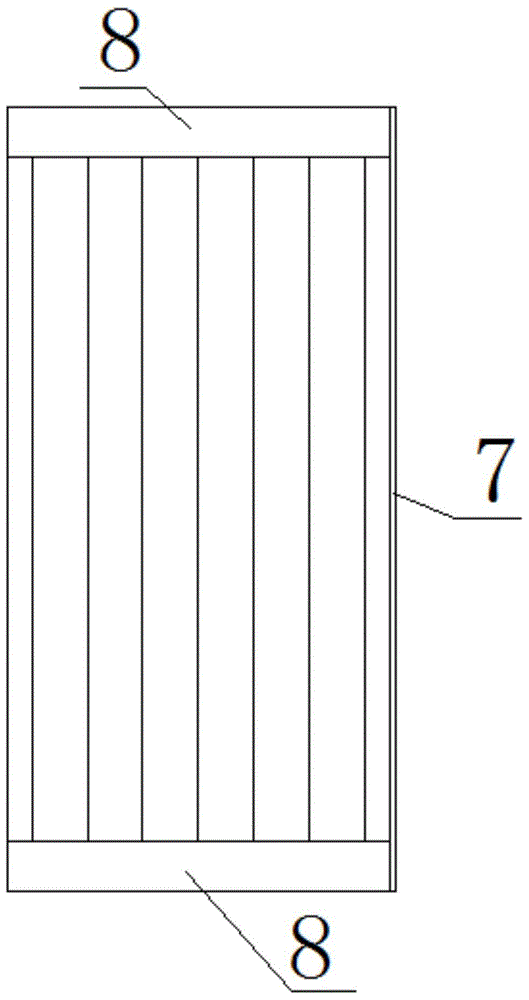

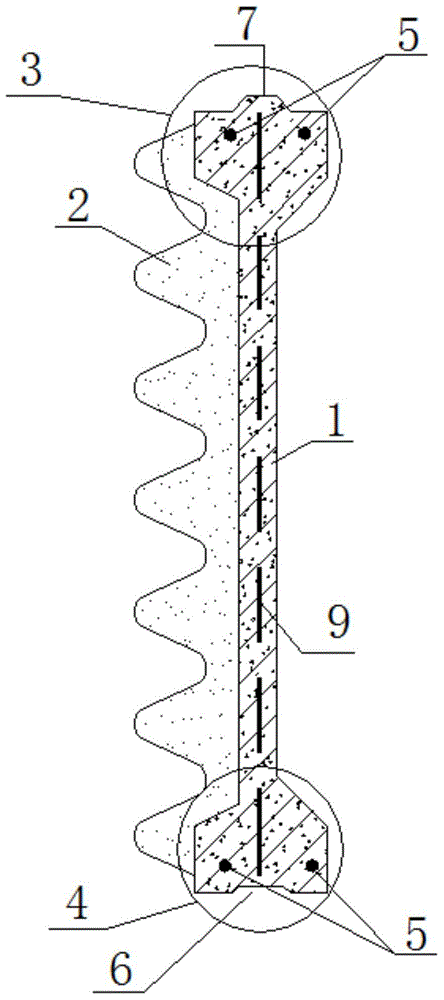

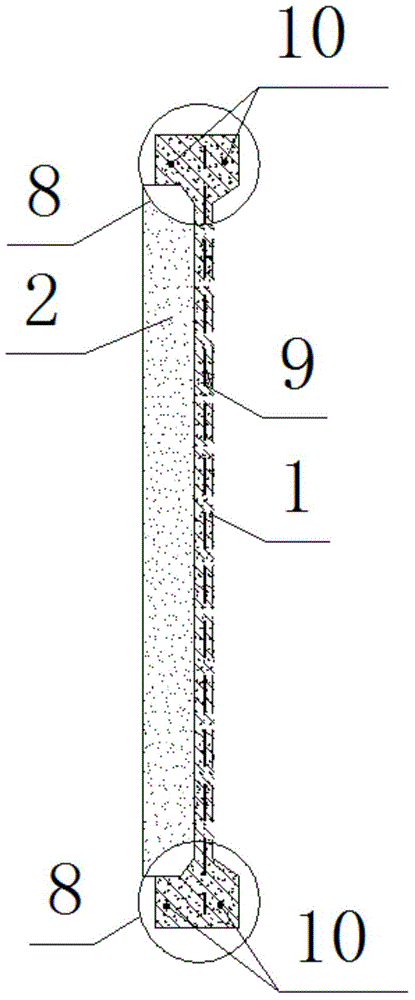

[0024] The technical solution of the present invention is further described in conjunction with the accompanying drawings. Figure 1 ~ Figure 3 The basic structure of the sound barrier unit plate involved in the present invention is shown. As shown in the figure, the prestressed concrete rib plate type sound barrier unit plate involved in the present invention includes a back plate 1 and a laminated layer 2, and the back plate 1 is made of high-strength concrete. Ribbed concrete thin slab is formed, and the superimposed layer 2 is composed of light volcanic rock sound-absorbing material attached to one side of the back plate 1. The laminated layer 2 and the back plate 1 are poured integrally to form a laminated component.

[0025] The back plate 1 is rectangular, and the upper and lower ends of the long side are provided with end ribs, and the upper and lower ends of the ribs are respectively provided with two prestressed steel wires 5, and the two sides of the short side are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com