Viscous material conveying pipe supporting device, supporting structure and concrete conveying machinery

A technology of support device and support structure, which is applied to pipeline supports, mechanical equipment, building structures, etc., and can solve the problems of unsatisfactory flexural rigidity, increased weight, and easy cracking of welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

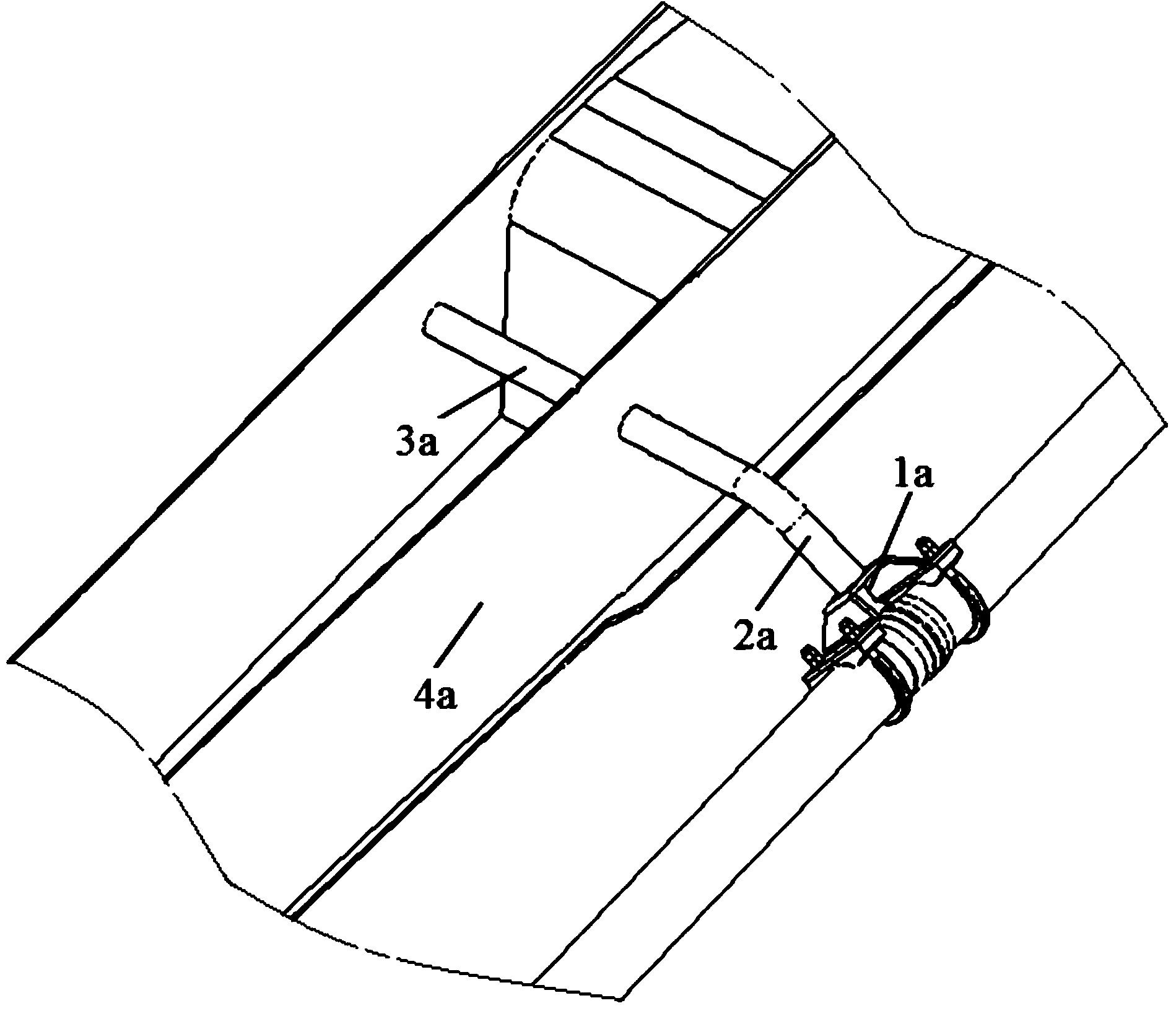

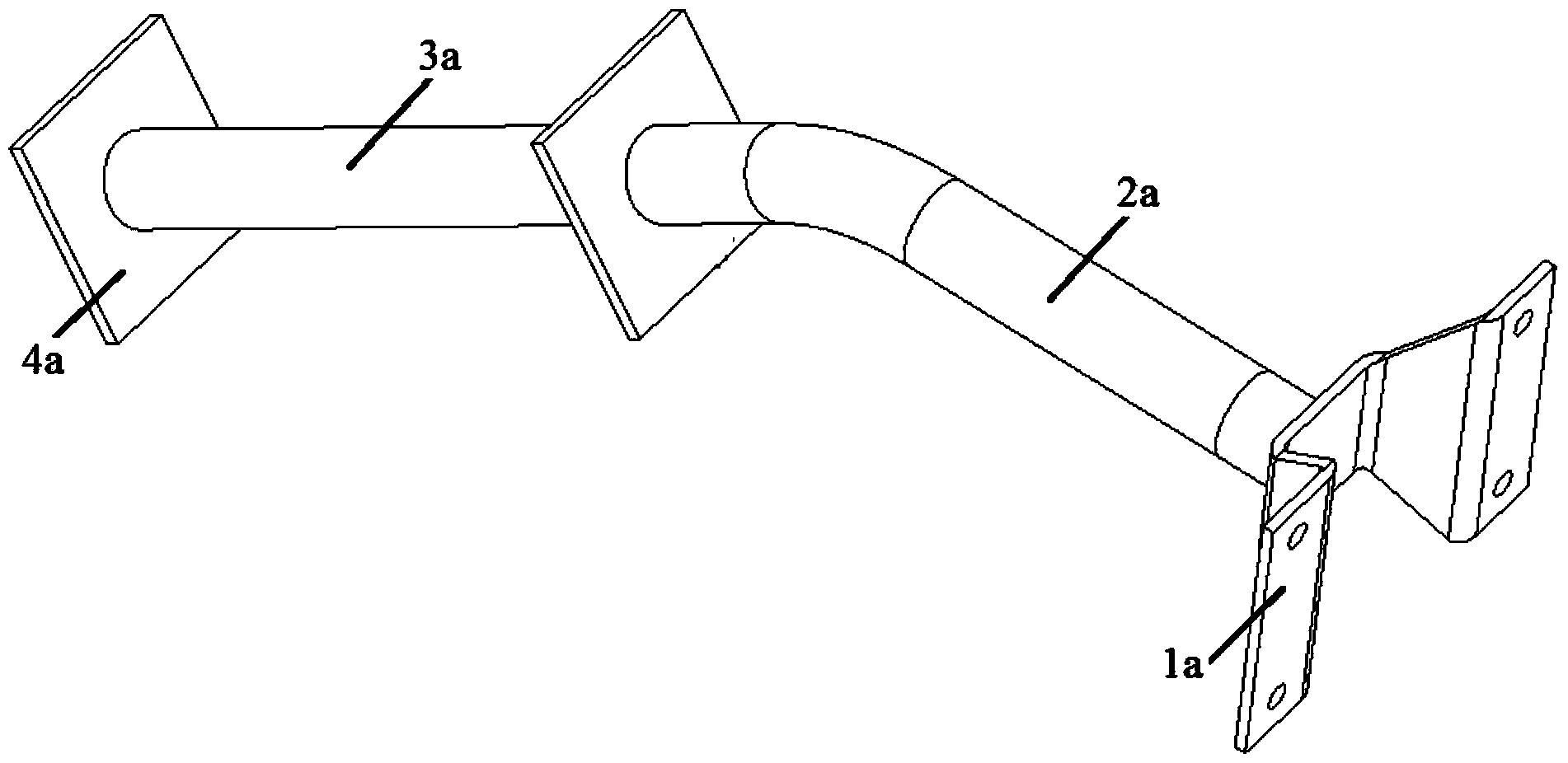

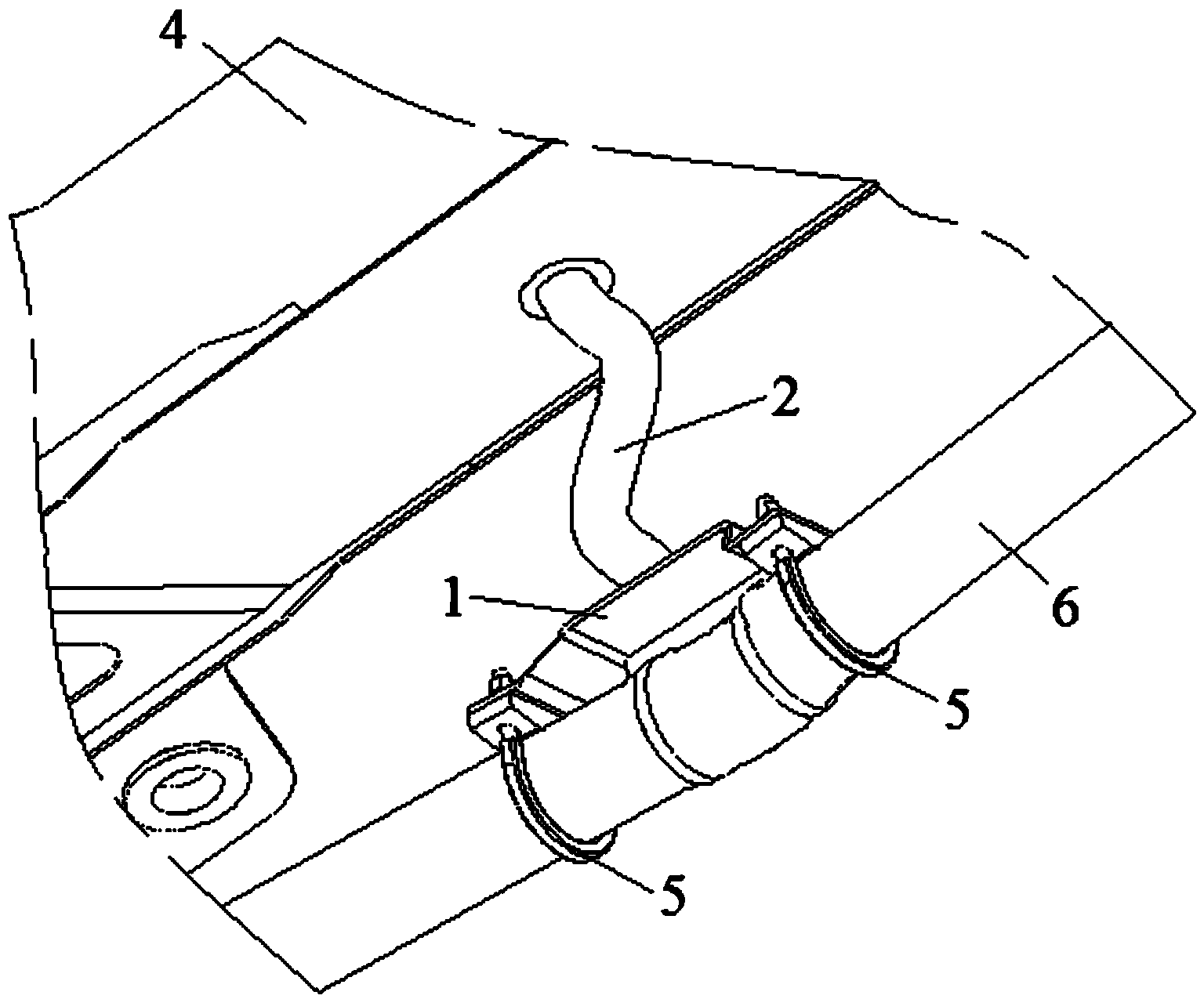

[0034]As mentioned above, the viscous material conveying pipe support structure in the prior art, such as the concrete pipe support structure on the concrete pump truck distribution boom, has a relatively low Large, that is, when a force is applied to the support pipe section along the concrete conveying direction, the support pipe section is not easy to be deflected and deformed, so that the impact load borne by the concrete pipe in the process of conveying materials will be directly transmitted to the concrete pipe support device At the welding position of the fixed section of the boom and the jib sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com