Churn compaction drill bit

A drill bit and extrusion technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., can solve the problems of inadaptability to rotary drilling conditions, unusable impact spear, complex structure, etc., so as to improve drilling efficiency and adapt well The effect of sex and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

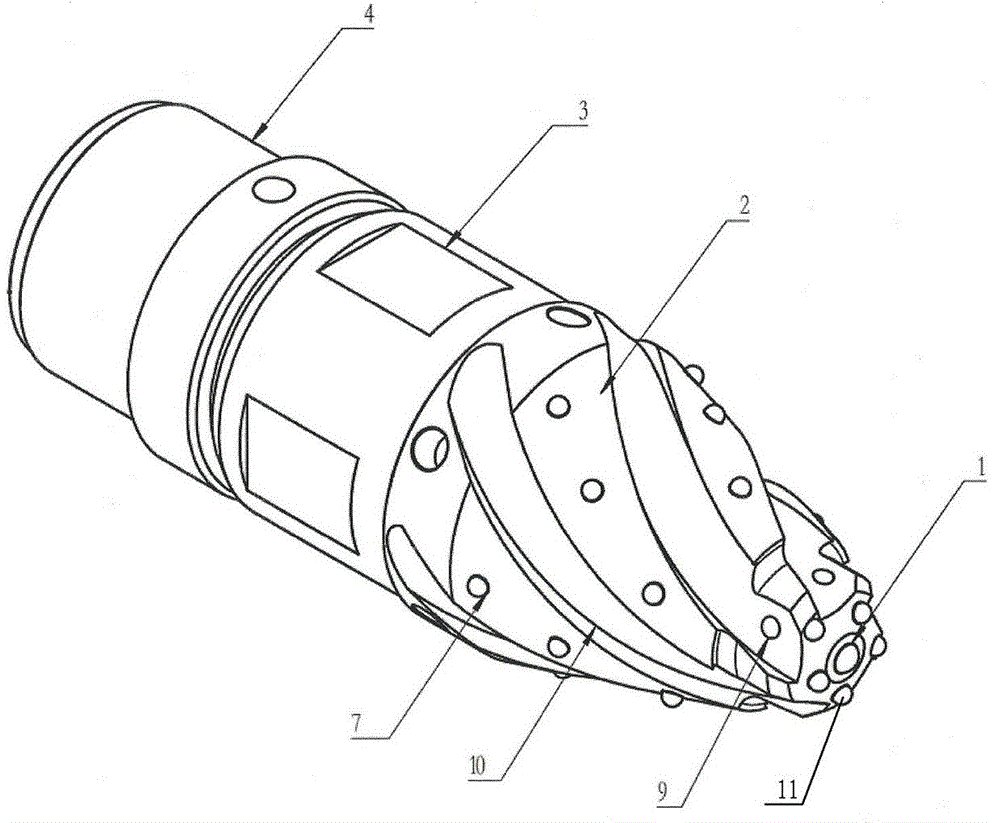

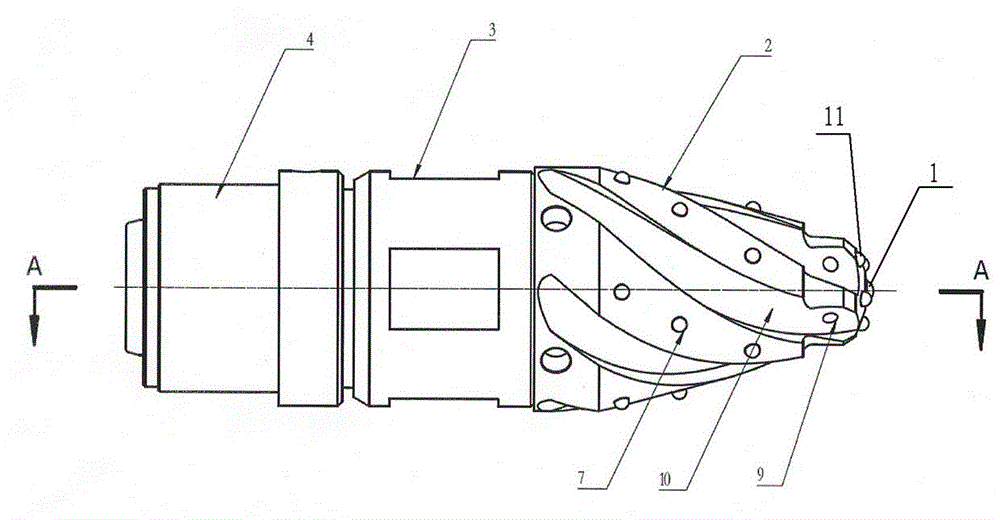

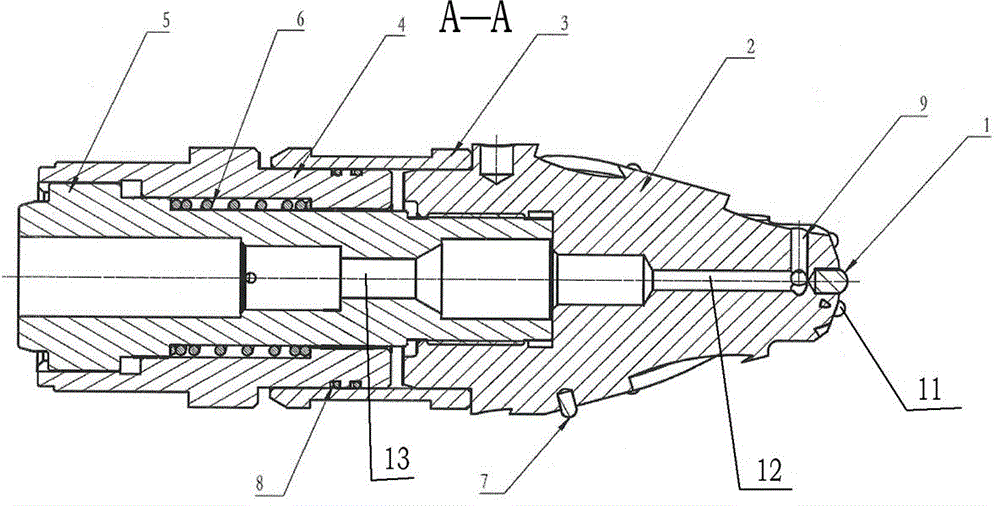

[0014] see figure 1 , figure 2 and image 3 Shown, the present invention is made of the first cemented carbide button 1, drill body 2, sealing cover 3, lower joint 4, anvil 5, return spring 6, the second carbide button 7, seal ring 8, the first Consisting of three carbide buttons 11, the inside of the drill bit body 2 has trapezoidal threads to connect with the anvil 5, the lower joint 4 is set on the anvil 5 and docked with the drill bit body 2, and the sealing cover 3 is set on the drill bit body 2 and the lower joint 4 Outer circumference, a sliding sealing ring 8 is set between the sealing cover 3 and the lower joint 4, the return spring 6 is located in the annular space formed by the anvil 5 and the lower joint 4, the first hard alloy button 1, the second hard alloy button The alloy button 7 and the third tungsten carbide button 11 are welded on the surface of the drill body 2, the first tungsten carbide button 1 is arranged at the center of the end of the drill body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com