Water pump shaft connecting bearing with sealing structure

A technology of sealing structure and water pump shaft, which is applied to the components of pumping devices for elastic fluid, pumps, pump components, etc., can solve the problem of bearing grease leakage, water ingress, easy wear, and practical effects of double-lip seal structure, etc. problems, to achieve the effect of reducing the wear rate of the bottom, preventing direct contact, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

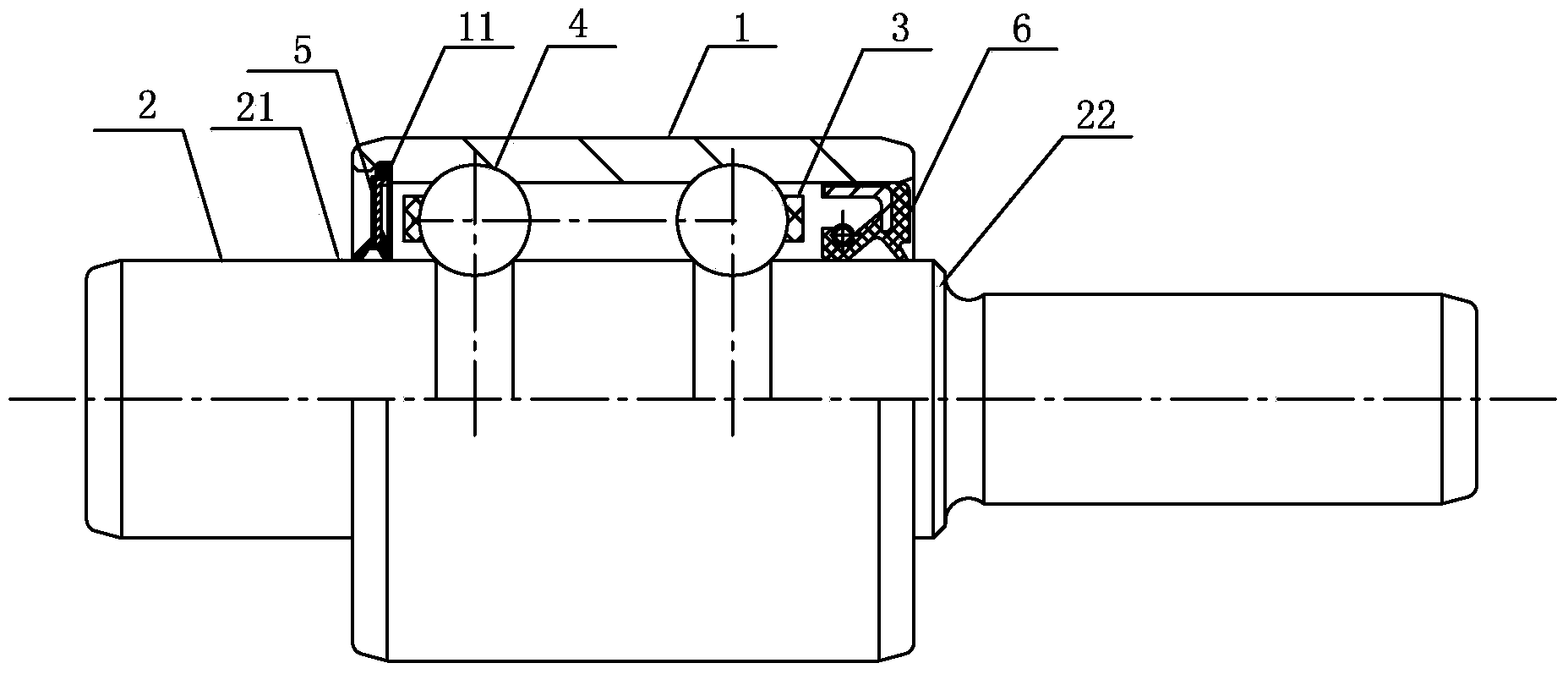

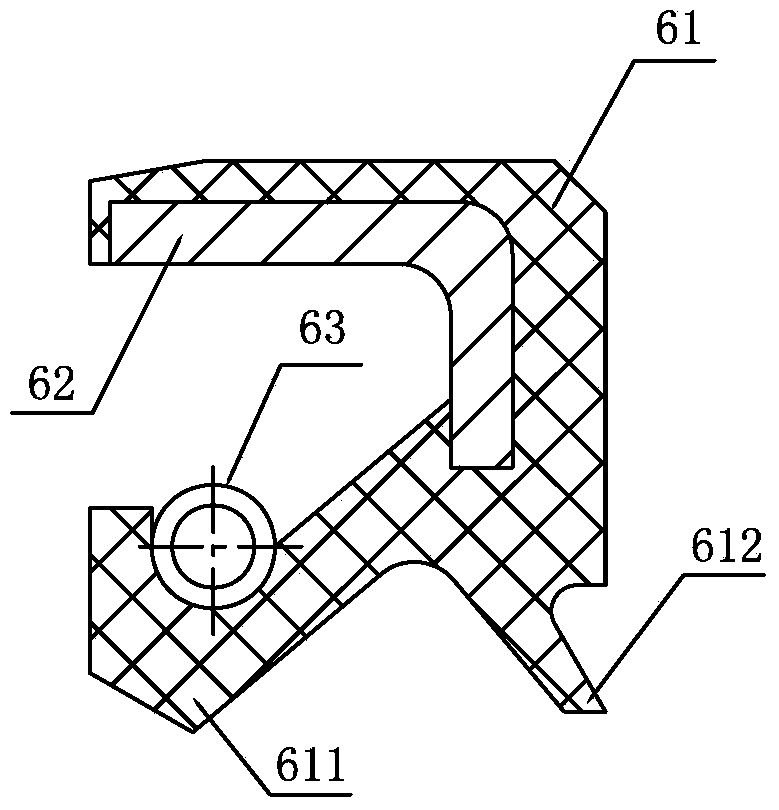

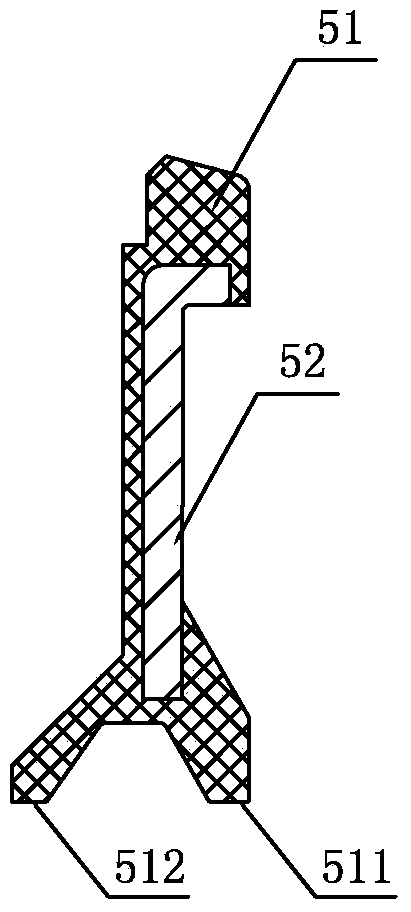

[0025] Such as figure 1 As shown, the water pump shaft-connected bearing with snap ring seal ring structure at the impeller end includes outer ring 1, shaft 2, rolling element 4, cage 3, double lip seal ring 5 and snap ring seal ring 6, etc., among which , the inner diameter of the outer ring 1 is provided with two outer raceways, the outer diameter of the shaft 2 is provided with two inner raceways corresponding to the outer raceways, and the cage 3 is installed between the outer ring 1 and the shaft 2 , the rolling element 4 is installed in the raceway between the outer ring 1 and the shaft 2 through the cage 3; the inner diameter of the outer ring 1 close to the flange end 21 is provided with a dust-proof sealing groove 11, and the dust-proof sealing groove 11 is located on the outer rolling The outer diameter of the double-lip sealing ring 5 is embedded in the above-mentioned dust-proof sealing groove 11, and the double lip on the inner diameter is in interference fit with...

Embodiment 2

[0032] Such as Figure 4 As shown, a shaft-connected bearing of a water pump with a composite seal structure at the impeller end, including an outer ring 1', a shaft 2', a rolling element 3', a cage 4', a double-lip seal ring 5' and belt Composite sealing structure 6' of the water throwing ring, etc., wherein, the inner diameter of the outer ring 1' is provided with two outer raceways, and the outer diameter of the shaft 2' is provided with two inner raceways corresponding to the outer raceways. The cage 4 is installed between the outer ring 1' and the shaft 2', and the rolling element 3' is installed in the raceway between the outer ring 1' and the shaft 2' through the cage 4'; the two inner diameters of the outer ring 1' Each side is provided with a dustproof sealing groove 11', and the dustproof sealing groove 11' is located on the outside of the two outer raceways of the outer ring 1'.

[0033] The structure and installation method of the above-mentioned double-lip seal r...

Embodiment 3

[0038] Such as Image 6 As shown, a shaft-connected bearing of a water pump with a composite seal structure at the impeller end, including an outer ring 1", a shaft 2", rolling elements 3", a cage 4", a double-lip seal ring 5" and a spinner Water ring 6" and so on, wherein, the inner diameter of the outer ring 1" is provided with two outer raceways, the outer diameter of the shaft 2" is provided with two inner raceways corresponding to the outer raceways, and the cage 4 "Installed between the outer ring 1" and the shaft 2", the rolling element 3" is installed in the raceway between the outer ring 1" and the shaft 2" through the cage 4"; both sides of the inner diameter of the outer ring 1" have a Dust-proof seal groove 11", the dust-proof seal groove 11" is located on the outside of the outer raceway; one end of the double-lip seal ring 5" is embedded in the dust-proof seal groove 11" of the outer ring 1", and the other end is connected to the shaft 2" interference fit; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com