Spanner for replacing 500-kV circuit spacer

A line interval and wrench technology, applied in the direction of wrenches, overhead line/cable equipment, wrenches, etc., can solve the problems of slow replacement, bulky and cumbersome, inconvenient operation, etc., and achieves weight reduction, volume reduction, convenient and labor-saving operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

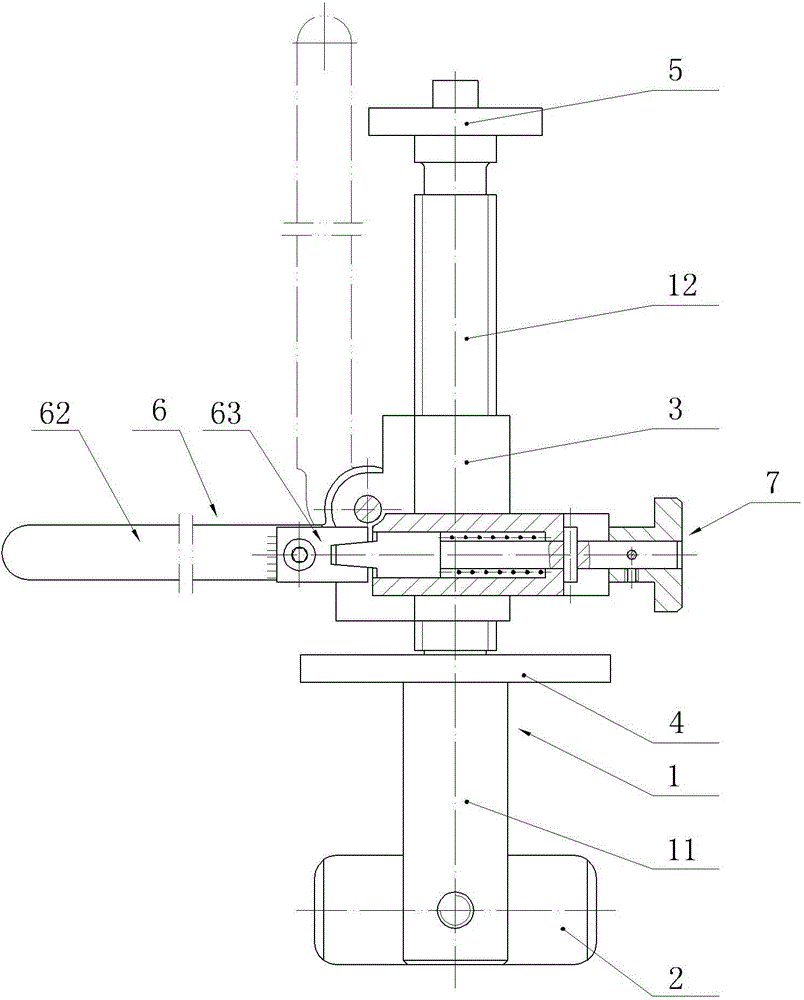

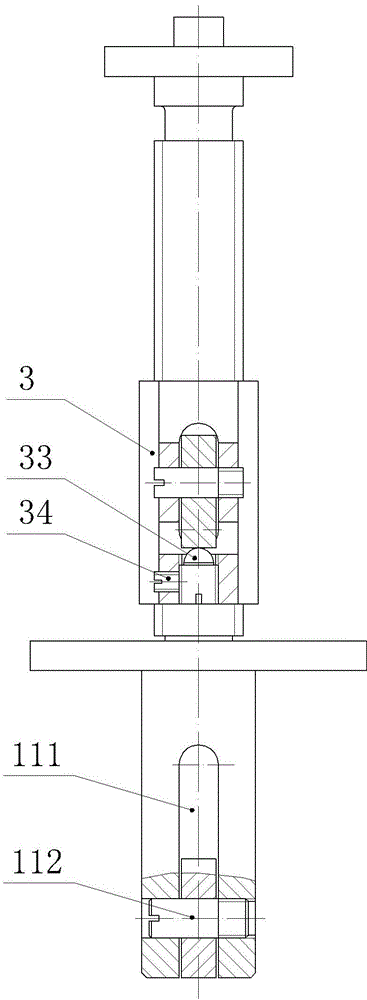

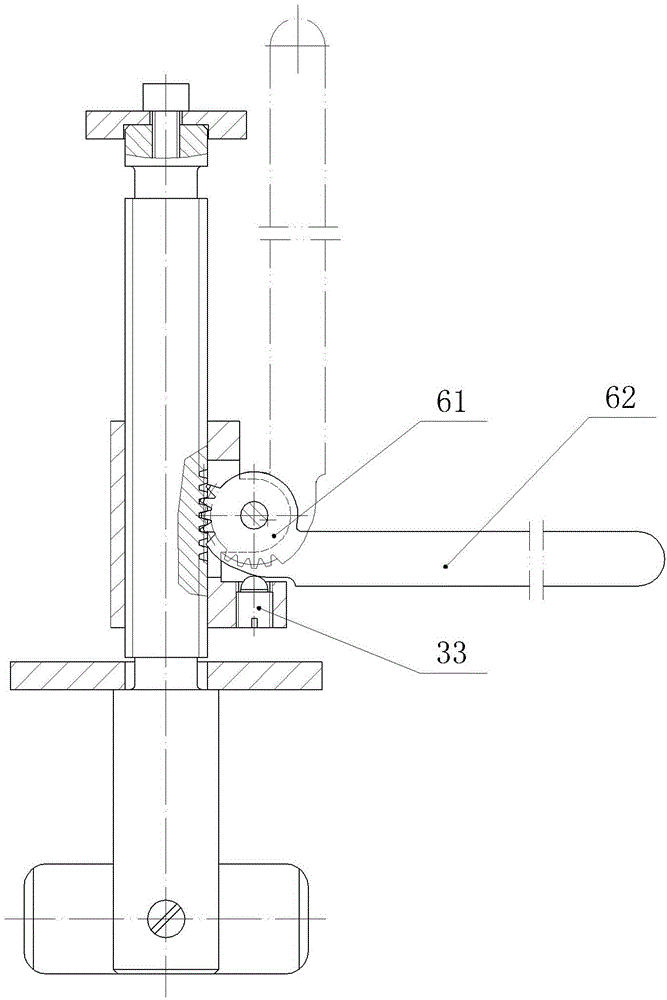

[0021] like Figure 1 to Figure 8 As shown, the wrench used to replace the 500kV line spacer provided by the present invention includes a screw rod 1, one end of which is a cylindrical rod 11 and the other end is a threaded rod 12, the diameter of the cylindrical rod 11 is greater than the diameter of the threaded rod 12, and the cylindrical rod 11 There is a rotatable pressing plate 2 in the axial center of the outer end of the outer end, which is used to compress the movable snap ring of the clamp of the spacer rod. The washer 4 is located between the cylindrical rod 11 and the moving seat 3, and the outer end of the threaded rod 12 has a retaining ring 5 for limiting the moving seat 3; the moving seat 3 is connected with a handle 6 and a locking member 7 for positioning the handle 6, The front end of the handle assembly 6 is a cam 61 , and the cam 61 has teeth engaged with threads on the threaded rod 12 for realizing the movement of the moving base 3 around the threaded rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com