A high shear dispersing emulsifier

A high-shear, emulsifier technology, used in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of inability to complete online production, wide particle size distribution range, large particle size, etc., and achieve good shearing effect. , Increase the shearing time and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Describe the present invention in detail below in conjunction with accompanying drawing:

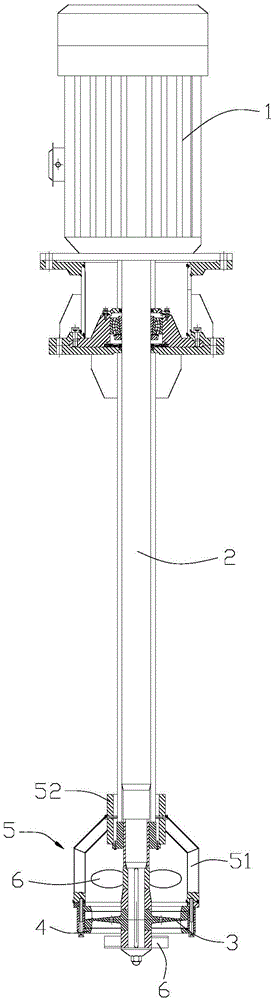

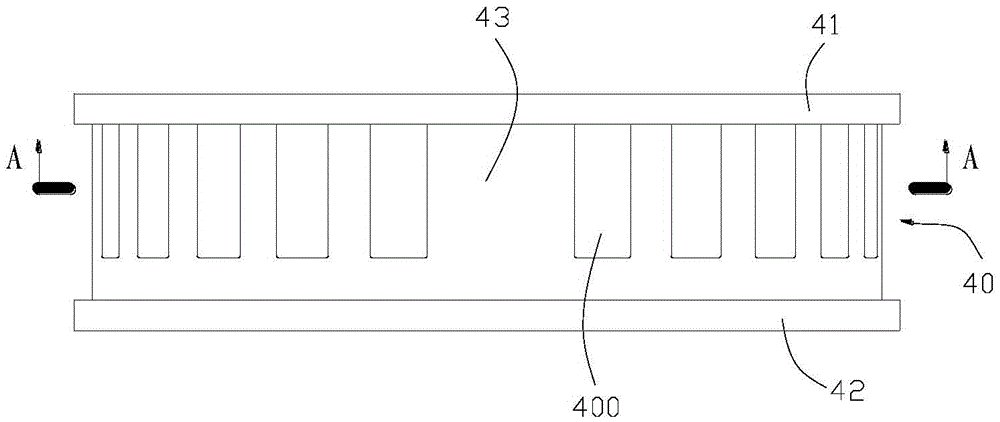

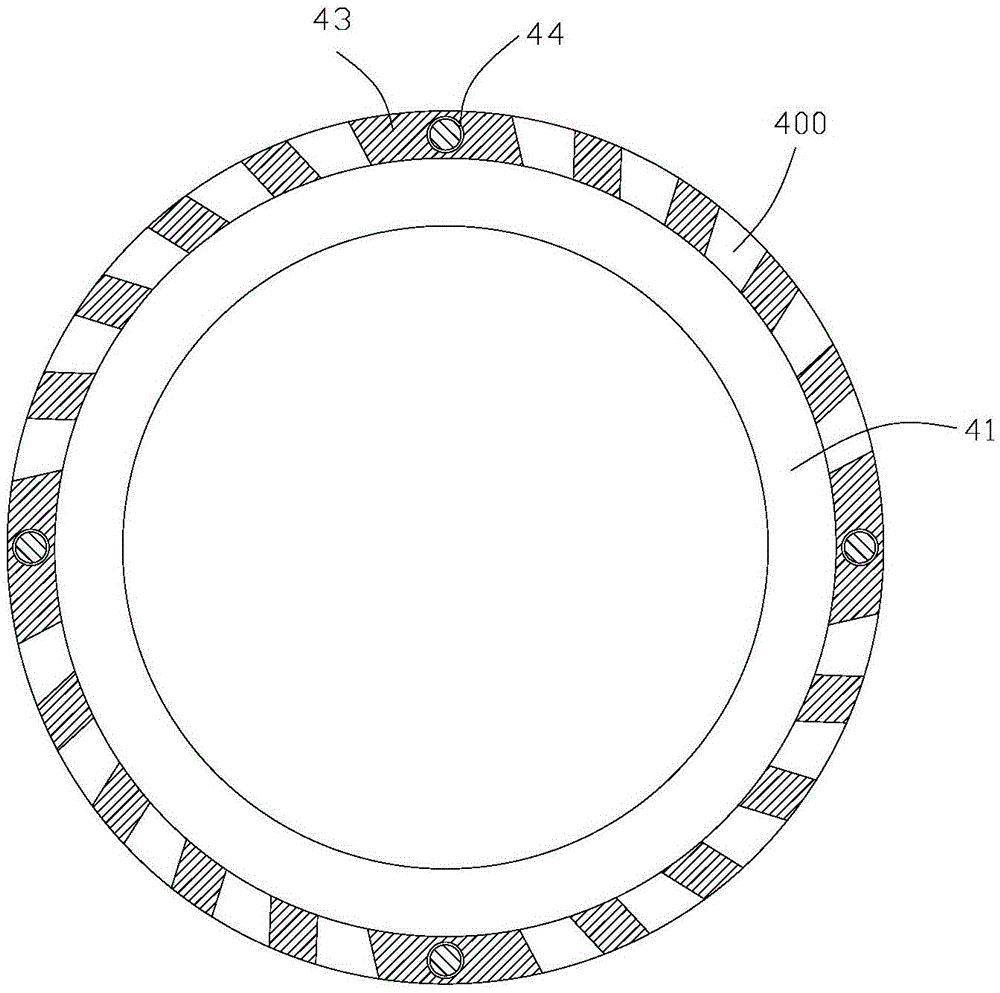

[0030] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It shows a high-shear dispersing emulsifier, which includes a vertical main shaft 2 connected to a motor 1 at the upper end, and the motor can directly clamp the main shaft through a clamp to drive its rotation. This method has a simpler structure and a smaller volume of the emulsifier , can also use coupling, belt drive to drive the main shaft, this way of transmission is more stable. A rotor 3 is connected to the lower end of the main shaft, and a stator 4 is mounted on the outer periphery of the rotor. The stator is fixed by a bracket 5 arranged between the upper and lower ends of the main shaft. The bracket adopts the first structure, such as figure 1 , which includes a shaft sleeve 51 sleeved on the lower part of the main shaft, and several support rods 52 are arranged between the shaft sleeve and the stator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com