A kind of enzymatic hydrolysis method of sea bass by-product and its application in emulsion products

A by-product, sea bass technology, applied in the field of enzymatic hydrolysis of sea bass by-products, can solve the problem of difficult and effective comprehensive utilization of leftovers, and achieve the effect of improving efficiency and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

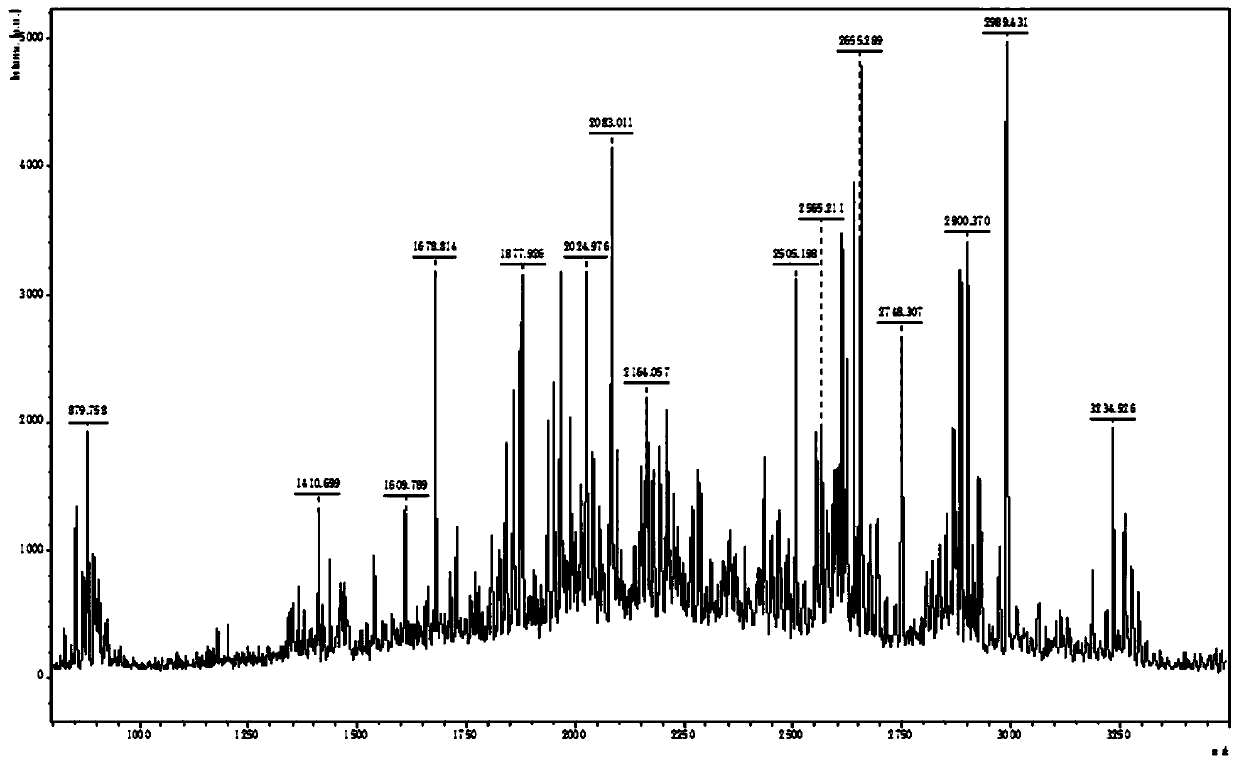

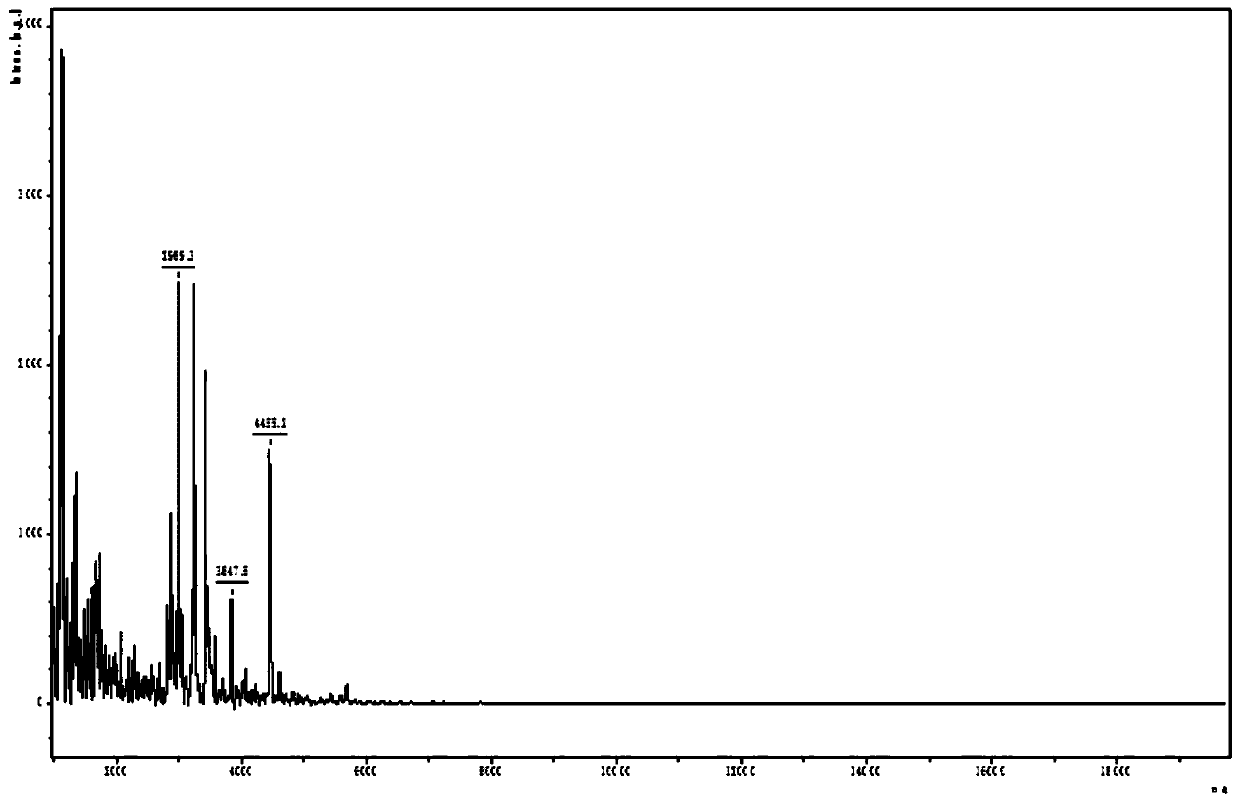

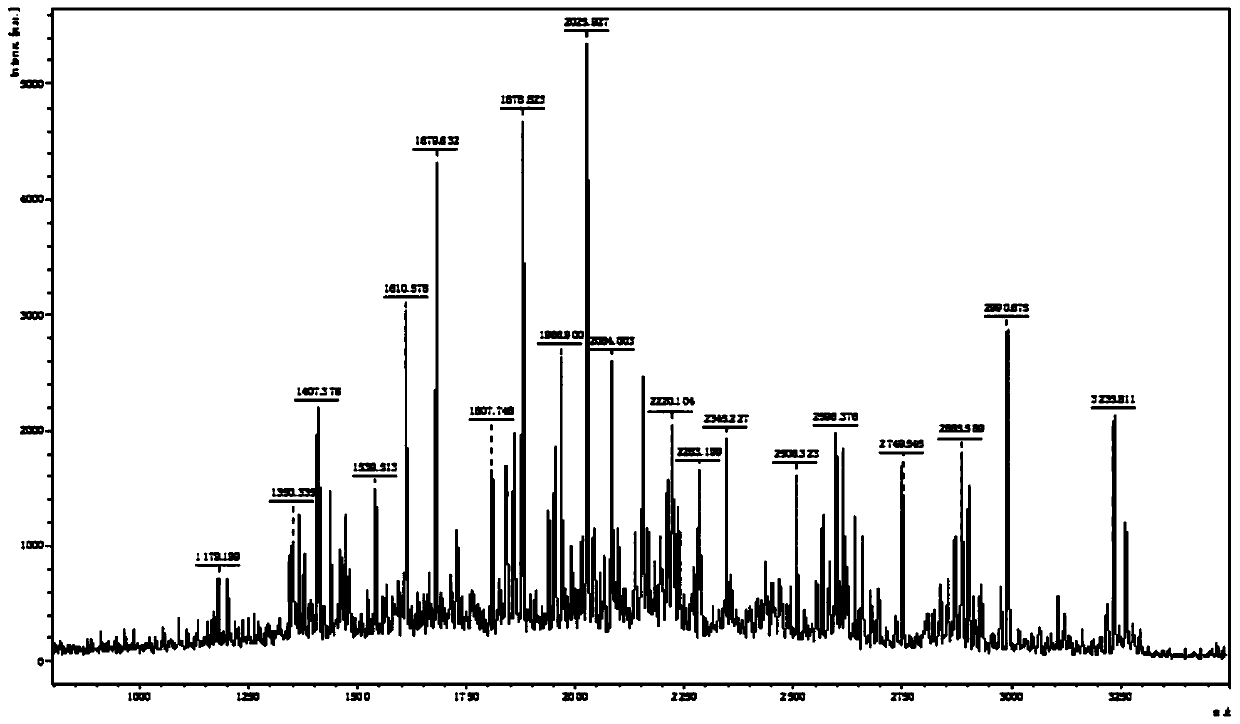

Image

Examples

Embodiment 1

[0055] Rinse the head, bone and skin of the fresh sea bass to remove the blood, drain the water, grind it with a meat grinder, mix the obtained minced fish, grind it again with a meat grinder, and distribute it for use.

[0056] Take an appropriate amount of leftovers, add petroleum ether at a mass ratio of 1:3 to degrease, stir for 1 hour, repeat 3 times, and naturally air-dry for 12 hours to obtain a by-product of defatted perch processing.

[0057] Take a certain amount of defatted perch processing by-products, adjust the mass volume ratio of feed water to 1:4, set the temperature of the magnetic stirrer at 50°C, preheat for half an hour, use alkali to adjust the pH to 9, add alkaline protease, enzyme The addition amount is 4000U / g, the enzymolysis temperature is 50°C, and the enzymolysis is 1.5h; inactivate the enzyme, use acid to adjust the pH value to 7, add flavor protease 4000U / g, the enzymolysis temperature is 50°C, and continue the enzymolysis for 1.5h. During the en...

Embodiment 2

[0065] Rinse the head, bone and skin of the fresh sea bass to remove the blood, drain the water, grind it with a meat grinder, mix the obtained minced fish, grind it again with a meat grinder, and distribute it for use.

[0066] Take an appropriate amount of leftovers, add petroleum ether at a mass ratio of 1:3 to degrease, stir for 2 hours, repeat twice, and naturally air-dry for 12 hours to obtain a by-product of defatted perch processing.

[0067] Take a certain amount of defatted perch processing by-products, mix it with water at a mass volume ratio of 1:4, set the temperature of the magnetic stirrer at 55°C, preheat for half an hour, adjust the pH to 9.5, add alkaline protease, and the amount of enzyme added 5000U / g, enzymatic hydrolysis for 2h; inactivate the enzyme; continue to adjust the temperature to 45°C, adjust the pH value to 7, add flavor protease 5000U / g, and enzymatic hydrolysis for 2h.

[0068] After the reaction was terminated by inactivating the enzyme in a ...

Embodiment 3

[0070] Rinse the head, bone and skin of the fresh sea bass to remove the blood, drain the water, grind it with a meat grinder, mix the obtained minced fish, grind it again with a meat grinder, and distribute it for use.

[0071] Take an appropriate amount of leftovers, add petroleum ether at a mass ratio of 1:4 to degrease, stir for 0.5 h, repeat 3 times, and naturally air-dry for 12 h to obtain a by-product of defatted perch processing.

[0072] Take a certain amount of defatted perch processing by-products, mix it with water at a mass volume ratio of 1:4, set the temperature of the magnetic stirrer at 50°C, preheat it for half an hour, adjust the pH to 9.2, add alkaline protease, and the amount of enzyme added 4500U / g, enzymolysis temperature is 50℃, enzymolysis 2.5h; inactivate the enzyme; adjust the pH value to 6.8, add flavor protease 4500U / g, enzymolysis temperature is 50℃, continue enzymolysis 2.5h.

[0073] After the reaction was terminated by inactivating the enzyme i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com