A kind of hydrogenation protection catalyst and its preparation and application

A hydrogenation protection and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the hydrogenation activity of the catalyst needs to be further improved, etc. achieve performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

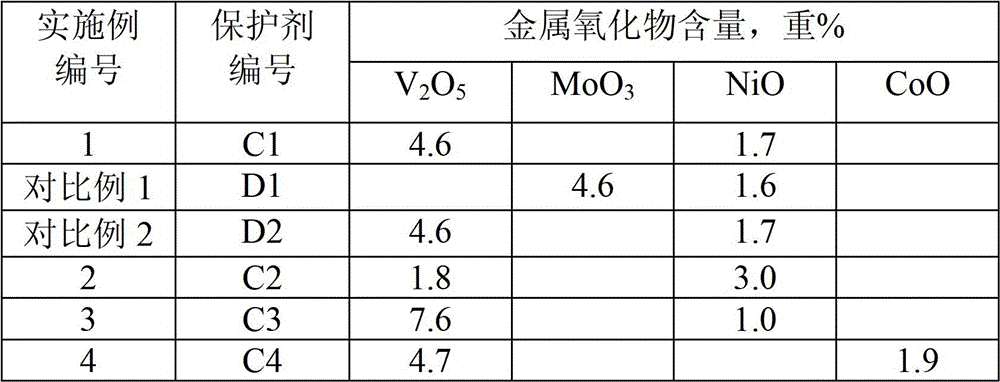

Embodiment 1

[0100] Take carrier Z1200g, use 500ml containing V 2 o 5 50 grams per liter, NiO14 grams per liter of ammonium metavanadate and nickel nitrate mixed solution with 20 milliliters of ethanol, after stirring and dissolving, adopt the excess impregnation method to impregnate the carrier with the above-mentioned aqueous solution (the impregnating solution by volume in the impregnating mixture is equal to The ratio of the carrier by weight is: 2.6), and the impregnation time is 0.1 hour. The impregnated mixture was placed in a high-pressure reactor for hydrothermal treatment. The conditions of the hydrothermal treatment included: the temperature was 150°C, the time was 4 hours; the pressure was 0.7MPa, wherein, P 0 =0.5MPa, ΔP=0.2MPa. The mixture obtained by hydrothermal treatment was cooled to room temperature, and after filtration, the obtained solid was dried at 120° C. for 2 hours, and then calcined at 450° C. for 3 hours to obtain the protective agent C1. The composition of ...

Embodiment 2

[0106] Take carrier Z1200g, use 500ml containing V 2 o 5 18 grams per liter, NiO24 grams per liter of ammonium metavanadate and nickel nitrate are mixed with 15 milliliters of isopropanol and stirred evenly, and the method of excessive impregnation is used to impregnate the carrier with the above-mentioned aqueous solution (the impregnating liquid in the impregnating mixture and The ratio of the carrier by weight is: 2.6), and the impregnation time is 0.2 hours. The impregnated mixture is placed in a high-pressure reactor for hydrothermal treatment. The conditions of hydrothermal treatment include: temperature is 200°C; time is 10 hours; pressure is 2.1MPa, wherein, P 0 =1.5MPa, ΔP=0.6MPa. The mixture obtained by hydrothermal treatment was cooled to room temperature, and after filtration, the obtained solid was dried at 120° C. for 2 hours to obtain protective agent C2. The composition of protective agent C2 is listed in Table 1.

Embodiment 3

[0108] Take carrier Z1200g, use 500ml containing V 2 o 5 70 grams per liter, the mixed solution of ammonium metavanadate and nickel nitrate of NiO8 grams per liter, adopt the method for excessive impregnation to impregnate the carrier with the above-mentioned aqueous solution (the ratio of the impregnating solution by volume and the carrier by weight in the impregnated mixture is : 2.5), the immersion time is 0.5 hours. The mixture obtained by impregnation is placed in a high-pressure reactor for hydrothermal treatment. The conditions of the hydrothermal treatment include: the temperature is 100 ° C; the time is 24 hours; nitrogen is introduced into the high-pressure reactor during the hydrothermal treatment to make the pressure in the high-pressure reactor is 5.2MPa, where P 0 =0.2MPa, ΔP=5.0MPa. The mixture obtained by hydrothermal treatment was cooled to room temperature, and after filtration, the obtained solid was dried at 120° C. for 2 hours, and then dried at 400° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com