High-temperature-resistant parallel clamp holder

A technology for parallel clamps and high temperature resistance, applied in the direction of operating devices, metal processing equipment, manufacturing tools, etc., can solve the problem that the clamping mechanism cannot be well dissipated to ensure work efficiency, achieve good heat dissipation effect, and enhance convective heat transfer , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

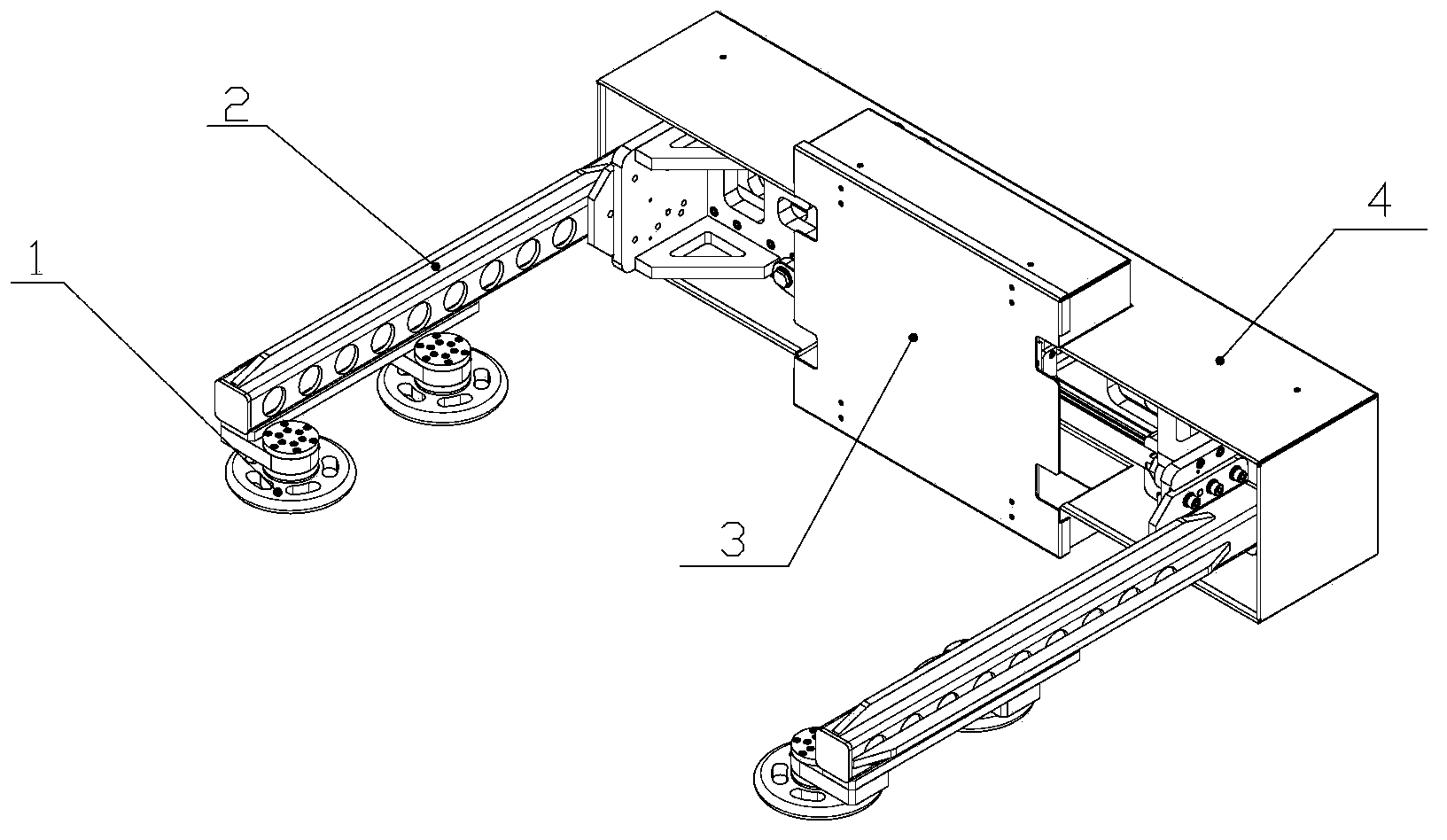

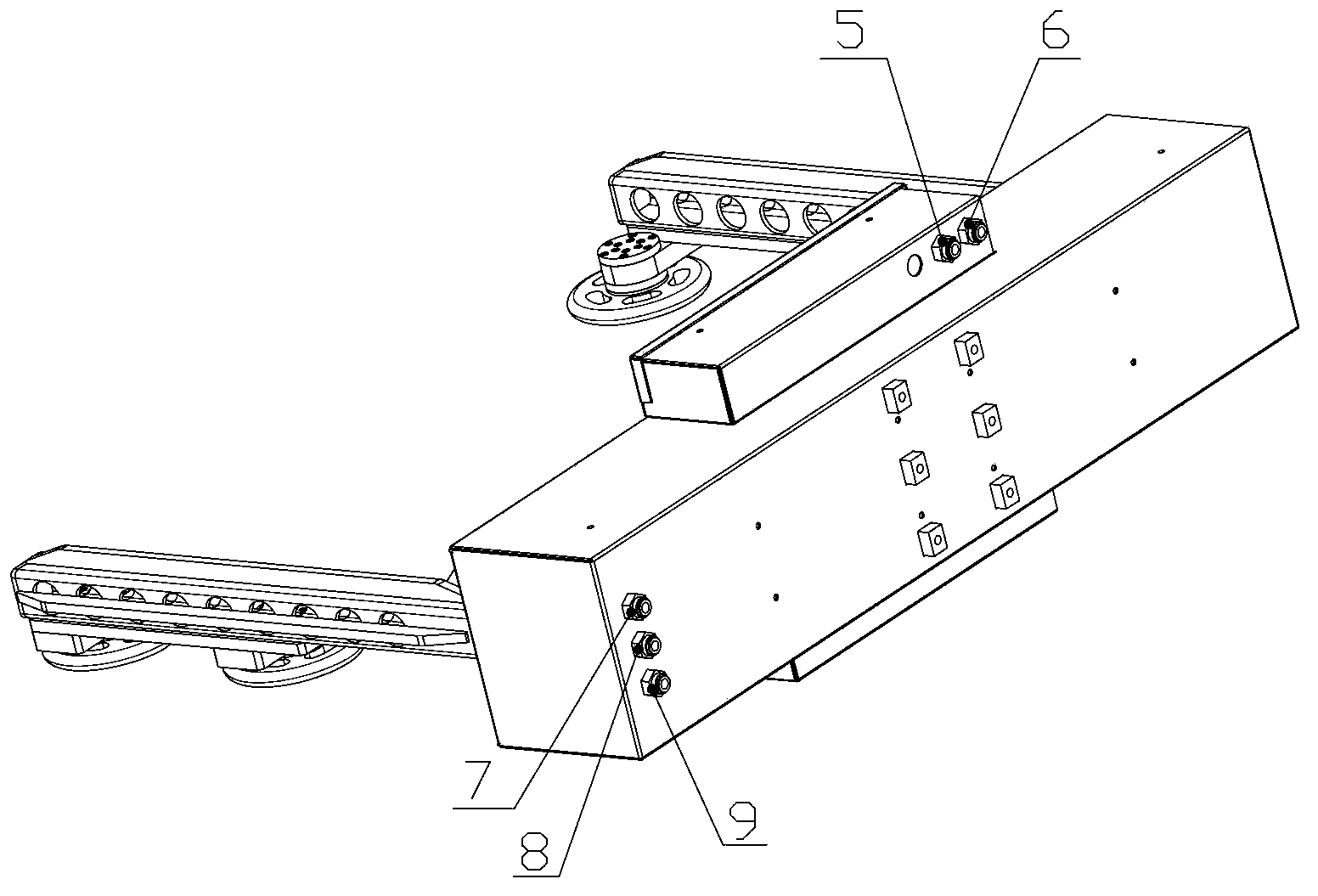

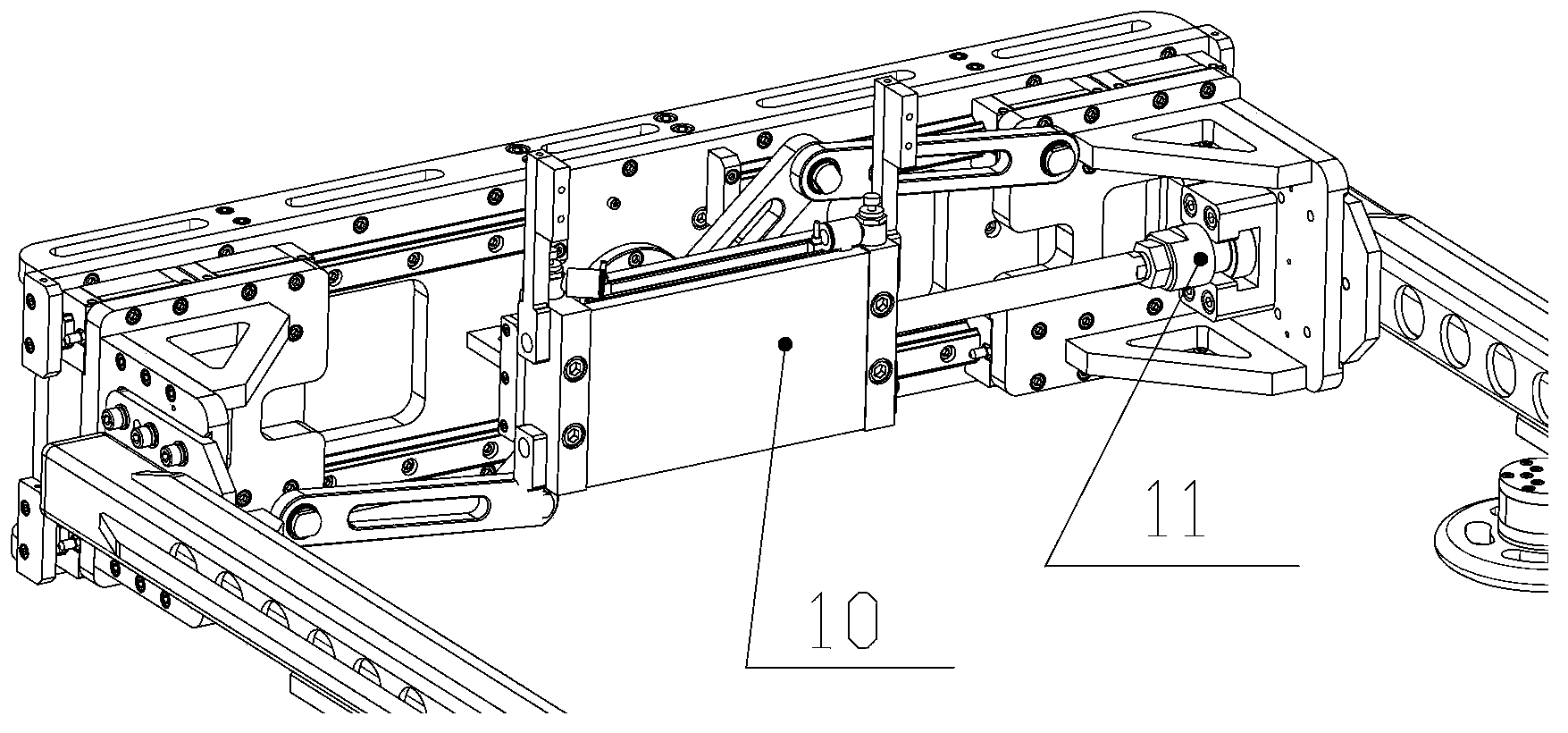

[0031] The invention discloses an effective high-temperature-resistant parallel clamper. The high-temperature-resistant parallel clamper can have good heat dissipation, lighter weight and higher work efficiency under the premise of ensuring functional requirements and economic costs. Moreover, the high-temperature-resistant parallel gripper can be quickly installed on the manipulator as a module without changing the existing structure.

[0032] The high-temperature-resistant parallel gripper includes a clamping beam, a rotating wheel installed on the clamping beam, a cavity, a cavity shell fixedly connected with the cavity, a cylinder fixed on the cavity, and a center-symmetrical cavity mounted on the cavity. The internal center symmetric slider crank mechanism, the clamping beam is connected and installed at both ends of the center symmetric slider crank mechanism, the cavity is provided with a first air hole and a second air hole to facilitate the forward and reverse movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com