Ti-Ni welding wire for welding Ti-pipeline steel composite board and preparation method of Ti-Ni welding wire

A pipeline steel and composite plate technology, applied in welding equipment, welding/welding/cutting items, welding media, etc., can solve problems such as inability to weld butt joints, and achieve the effects of large-scale production, simple preparation process, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

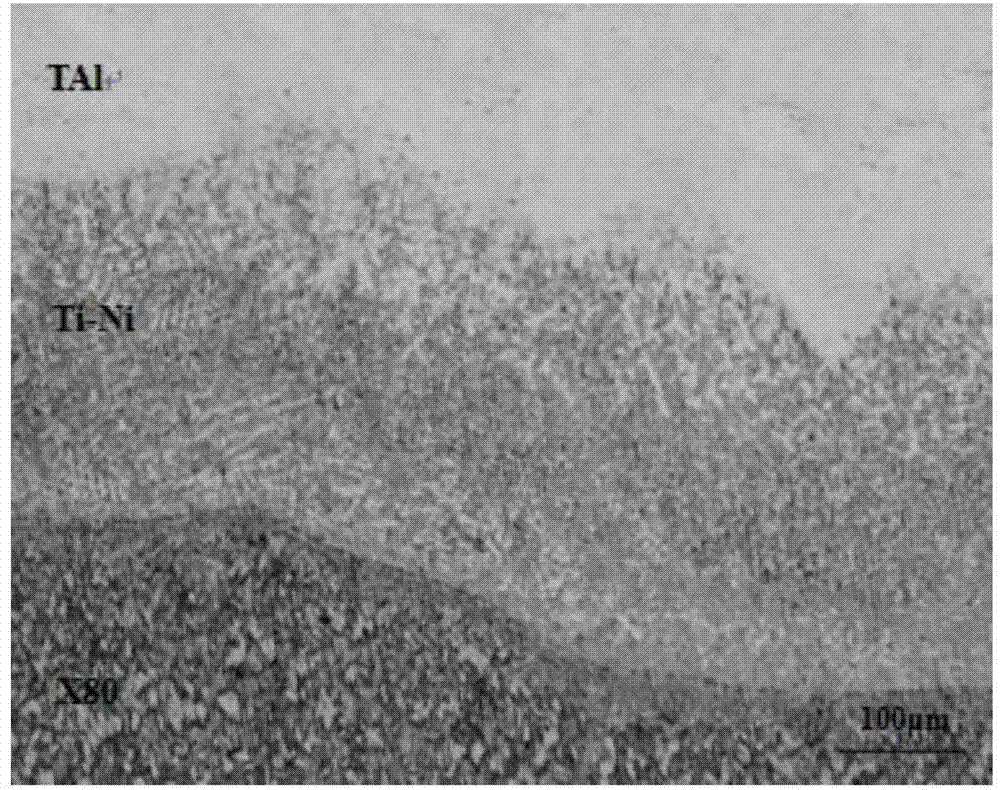

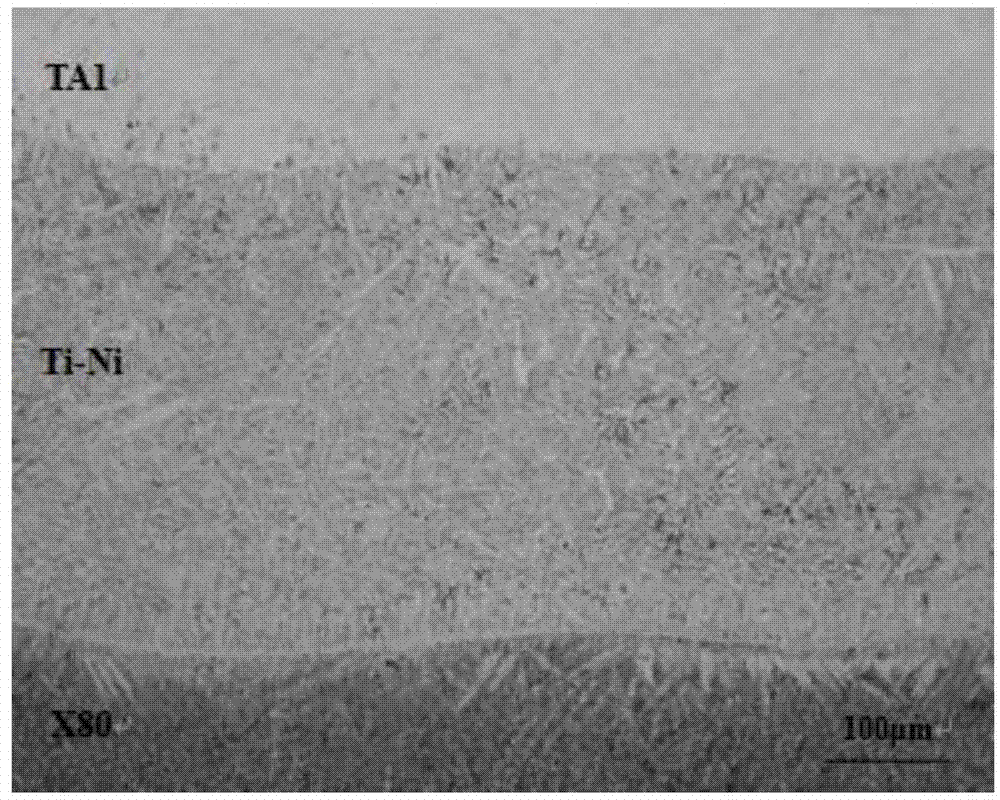

Image

Examples

preparation example Construction

[0022] The preparation method of the above-mentioned titanium-pipeline steel composite plate welding Ti-Ni welding wire, the specific steps are as follows:

[0023] Step 1, Smelting

[0024] Weigh 52-58% of pure nickel powder and 42-48% of titanium sponge according to the weight percentage respectively; put the weighed titanium sponge into the MgO crucible in the vacuum induction melting furnace for melting; after the titanium sponge is completely melted into molten steel Refining, the refining temperature is 1680°C, the time is 20min, then the temperature of molten steel is lowered to 1550°C, and then filled with argon to make the pressure in the furnace reach 300-380mmHg; then add the weighed pure nickel powder into the molten steel and stir After 2 minutes, the steel is tapped, the temperature of the steel is 1480°C, and it is poured into the ingot mold. During the pouring process, the temperature of the molten steel should be kept at 1480°C. Store in a vacuum chamber for ...

Embodiment 1

[0030] Step 1, Smelting

[0031] Weigh 52% of pure nickel powder and 48% of sponge titanium according to the weight percentage; put the weighed sponge titanium into the MgO crucible in the vacuum induction melting furnace for melting; after the sponge titanium is completely melted into molten steel, refine and refine The temperature is 1680°C, the time is 20min, then the temperature of molten steel is lowered to 1550°C, and then argon is filled to make the pressure in the furnace reach 350mmHg; then the weighed pure nickel powder is added into the molten steel and stirred for 2min, and then the steel is tapped. The temperature of the steel is 1480°C, and it is poured into the ingot mold. During the pouring process, the temperature of the molten steel should be kept at 1480°C. At the same time, the surface of the molten steel should be calm and the pouring should be uniform. Take out the ingot and cool to room temperature; during the smelting process, the weight percentage of e...

Embodiment 2

[0038] Step 1, Smelting

[0039]Weigh 54% of pure nickel powder and 46% of sponge titanium according to weight percentage; put the weighed sponge titanium into the MgO crucible in the vacuum induction melting furnace for melting; after the sponge titanium is completely melted into molten steel, refine and refine The temperature is 1680°C, the time is 20min, then the temperature of the molten steel is lowered to 1550°C, and then filled with argon to make the pressure in the furnace reach 360mmHg; then the weighed pure nickel powder is added to the molten steel and stirred for 2min, and then the steel is tapped. The temperature of the steel is 1480°C, and it is poured into the ingot mold. During the pouring process, the temperature of the molten steel should be kept at 1480°C. At the same time, the surface of the molten steel should be calm and the pouring should be uniform. Take out the ingot and cool to room temperature; during the smelting process, the weight percentage of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com