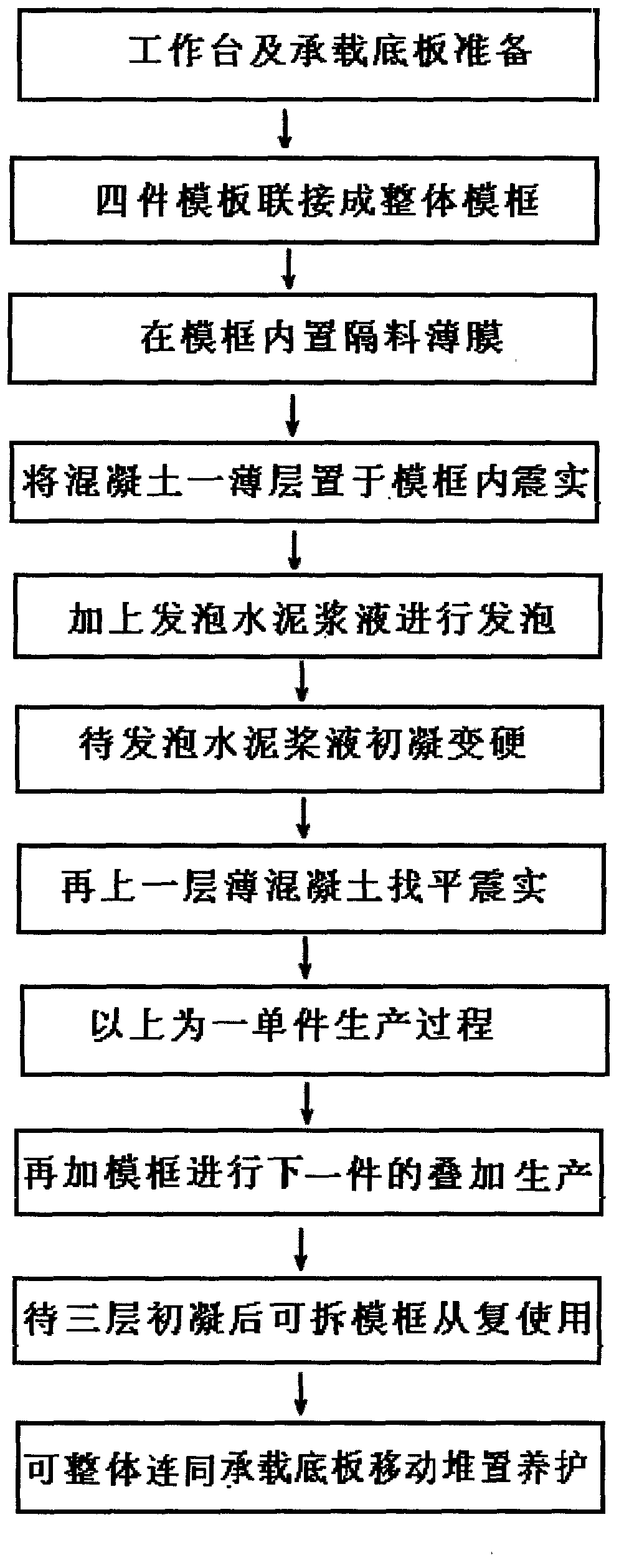

Three-layer concrete thermal insulation wallboard superposition method production process

A production process and technology for thermal insulation wall panels, applied in the direction of layered products, hydraulic material layered products, manufacturing tools, etc., can solve the problem of no three-layer concrete thermal insulation board production technology, etc. The effect of reducing manufacturing cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

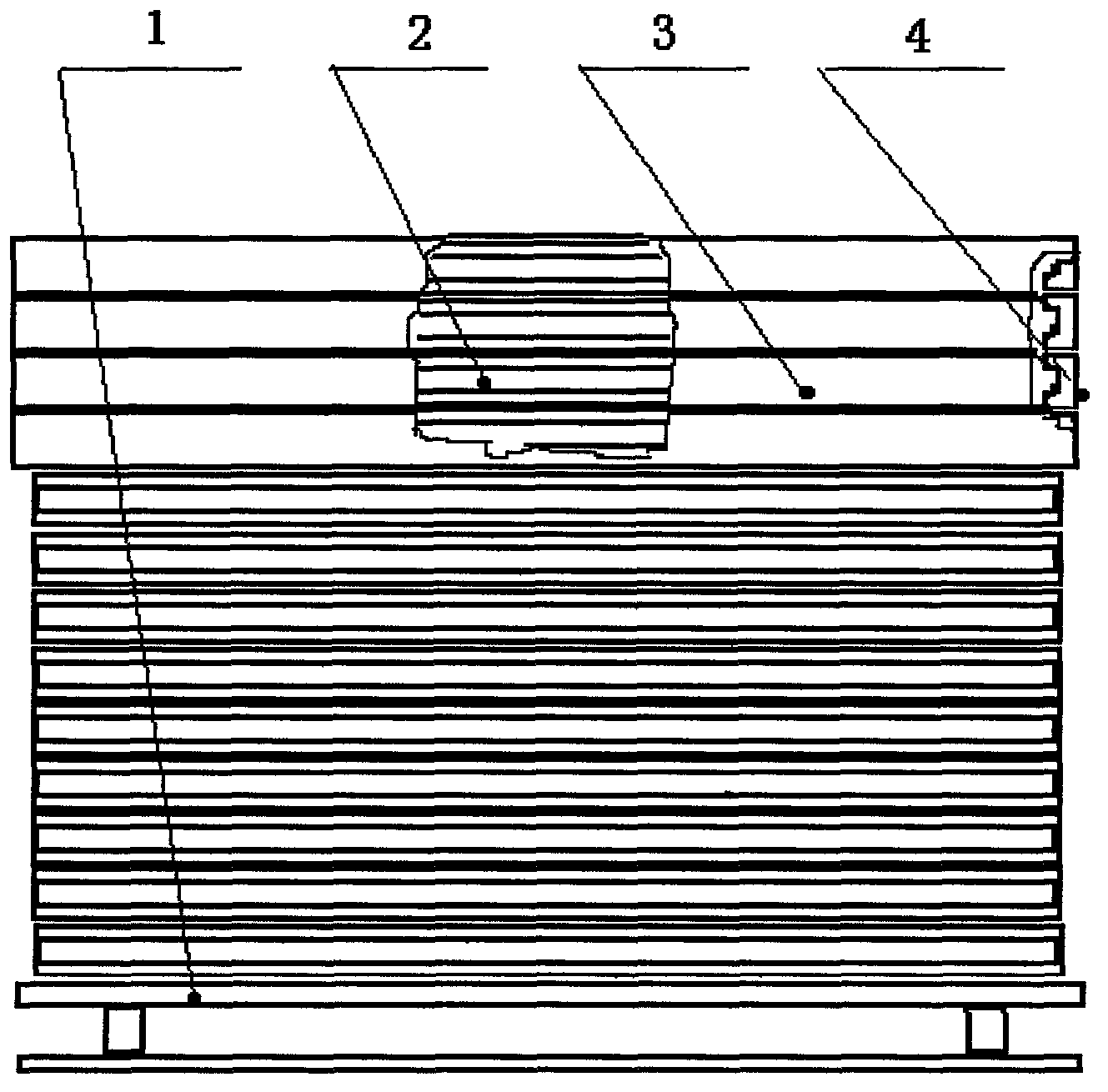

[0010] Put a load-bearing base plate 1 on the operating platform, combine two 150-250 cm long molds 3 and two 60 cm short molds 4 into a doorframe-shaped mold frame, put it on the load-bearing base plate 1, and build a layer of film in the mold frame. Spread the concrete one or two centimeters on the film, shake it mechanically, pour the foamed cement slurry on the concrete to foam for 8-15 centimeters, wait for the initial setting of the foaming liquid to reach a certain hardness, and then spread the concrete one or two centimeters, after After the vibration leveling is parallel to the mold, the pouring of the single product is completed.

[0011] Place the mold frame on the mold frame of the poured product to carry out the repeated production of the next piece. When the lower part of the product has been poured, and the three-layer side has been initially set without molds and will not be deformed, the mold frame can be removed for use in rotation when the upper part is pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com