Material sawing mechanism of full-automatic brick cutting machine

A fully automatic cutting machine technology, which is applied in the field of cutting machines and special cutting machines for blocks, can solve the problems of small blocks that are difficult to support, increase construction costs, and have a lot of scraps, so as to achieve fully automated operations and improve The effect of sawing efficiency and precise size of sawdust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

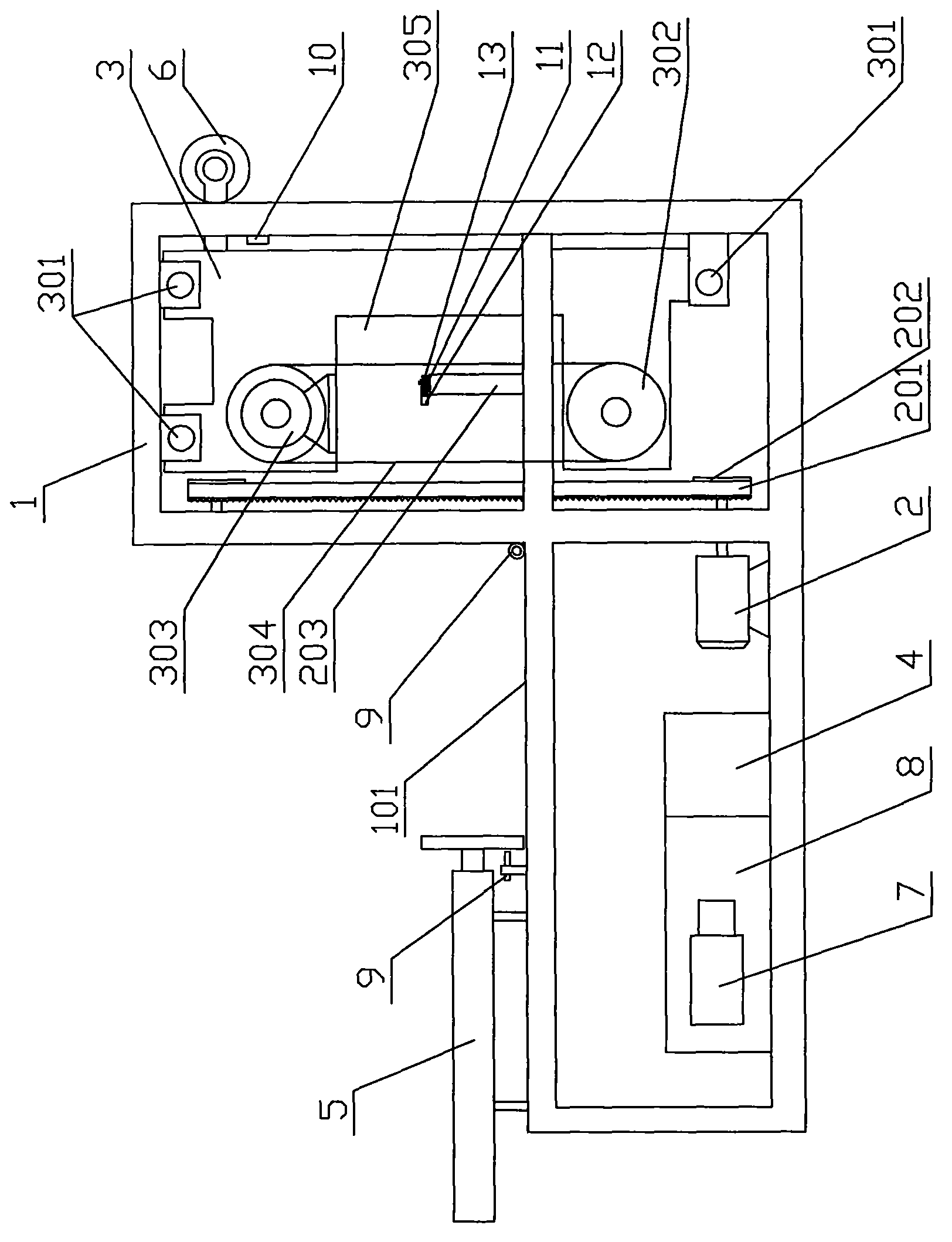

[0012] Depend on figure 1 As shown, the sawing mechanism of the automatic block cutting machine mainly includes a frame 1, a longitudinal sawing mechanism and a horizontal sawing mechanism, and the longitudinal sawing mechanism mainly includes a longitudinal drive motor 2, a longitudinal band saw 201 , the longitudinal paired pulleys 202 and the material baffle 203, the longitudinal paired pulleys 202 are distributed up and down and installed on the frame 1, the longitudinal drive motor 2 is connected to one of the pulleys 202, and the longitudinal band saw 201 is wound around the longitudinal On the pulley 202, use the longitudinal band saw 201 to perform longitudinal sawing operations on the material, the frame 1 is provided with a sawing platform 101, and the material baffle 203 is installed on the sawing platform 101 of the frame 1; The horizontal sawing mechanism mainly includes a horizontal saw frame 3, a horizontal rail 301, a pair of lateral pulleys 302, a horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com