Automatic packaging system for medical waste

A packaging system and medical waste technology, applied in the field of medical devices, can solve the problems of irregular replacement, easy to be broken, unable to achieve sealing, etc., and achieve the effects of reasonable structure, strong operability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

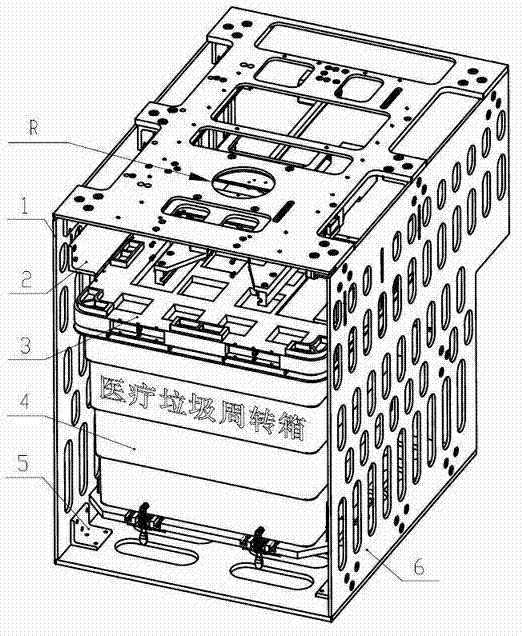

[0028] from Figure 1 to Figure 8 It can be seen that the automatic packaging system for medical waste includes a split shell frame, a box body lifting mechanism, a box cover grabbing mechanism, a box cover moving mechanism, a garbage bin body, and a quick sealing mechanism.

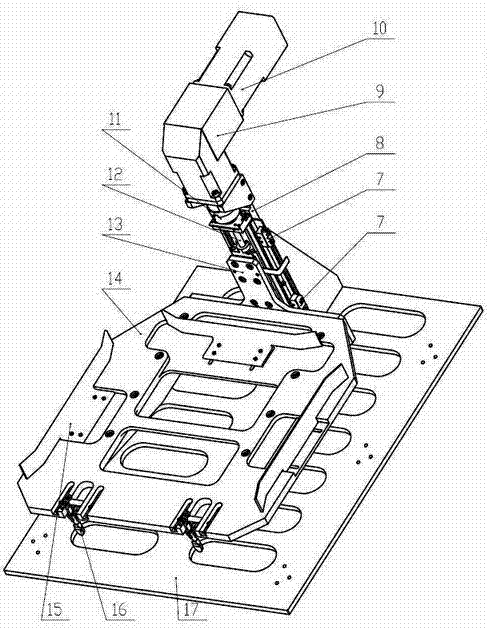

[0029] from figure 2It can be seen that the box lifting mechanism is provided with a lifting motor 10, a linear actuator 12, a bracket 14, a base plate 8, and the like. Among them, the linear actuator 12 is fixed on the base plate 8, the lifting motor 10 is connected to the main shaft of the linear actuator 12 through the reducer 9 and the coupling 11, and the bracket 14 is fixed together with the slider of the linear actuator 12 through the connecting plate 13 ; The entire lifting mechanism is connected to the bottom plate 17 of the frame through the base plate 8 ; thus, the rotary motion of the lifting motor 10 can be converted into the lifting motion of the bracket 14 . A box body limit block 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com