Hydraulic lifting system of attached tower crane

A tower crane and attached technology, applied in cranes, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of attached tower cranes and personnel safety hazards, unfavorable energy saving, shortened hydraulic system life, etc. The effect of reducing safety hazards, increasing safety and reducing commutation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

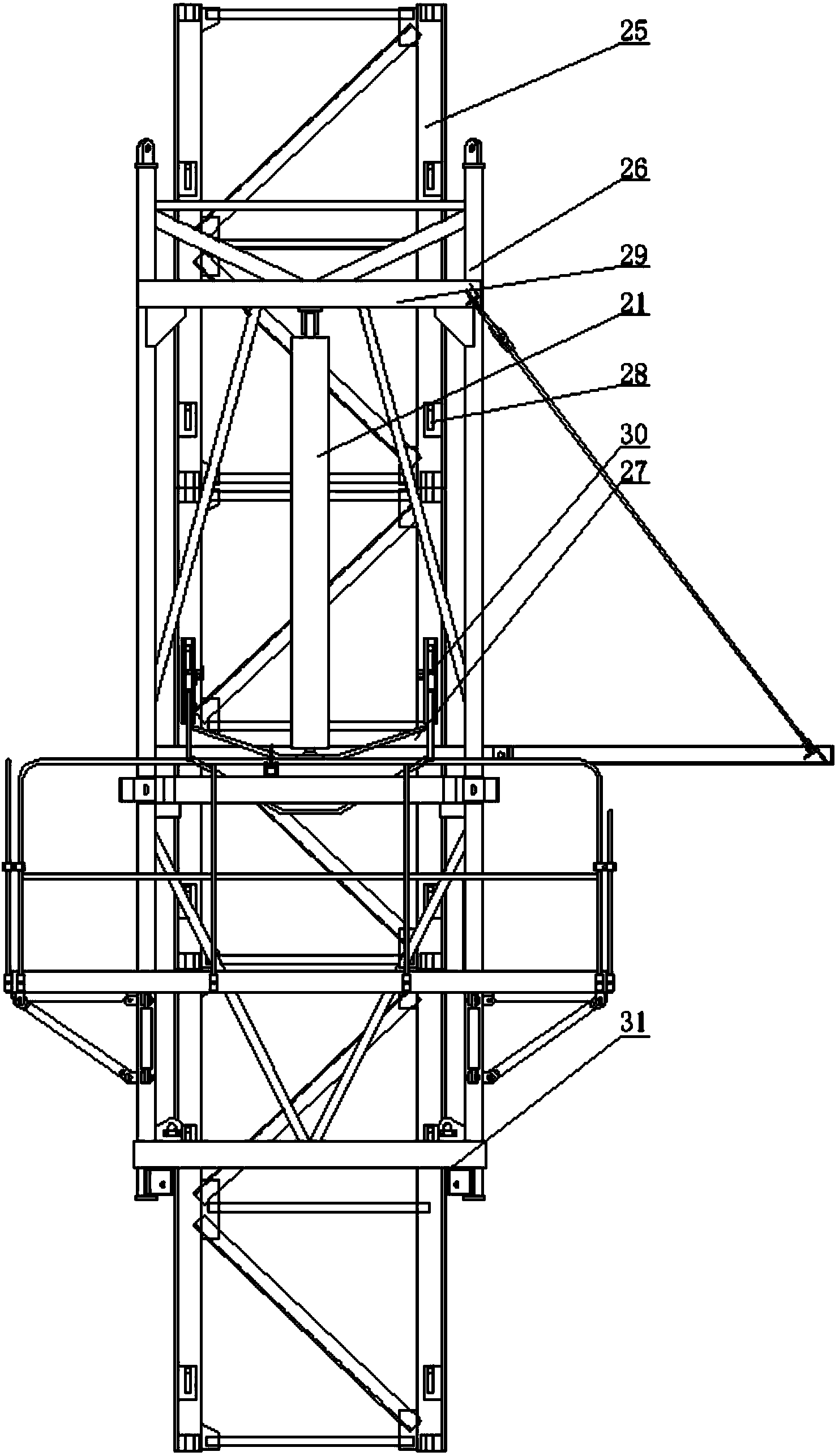

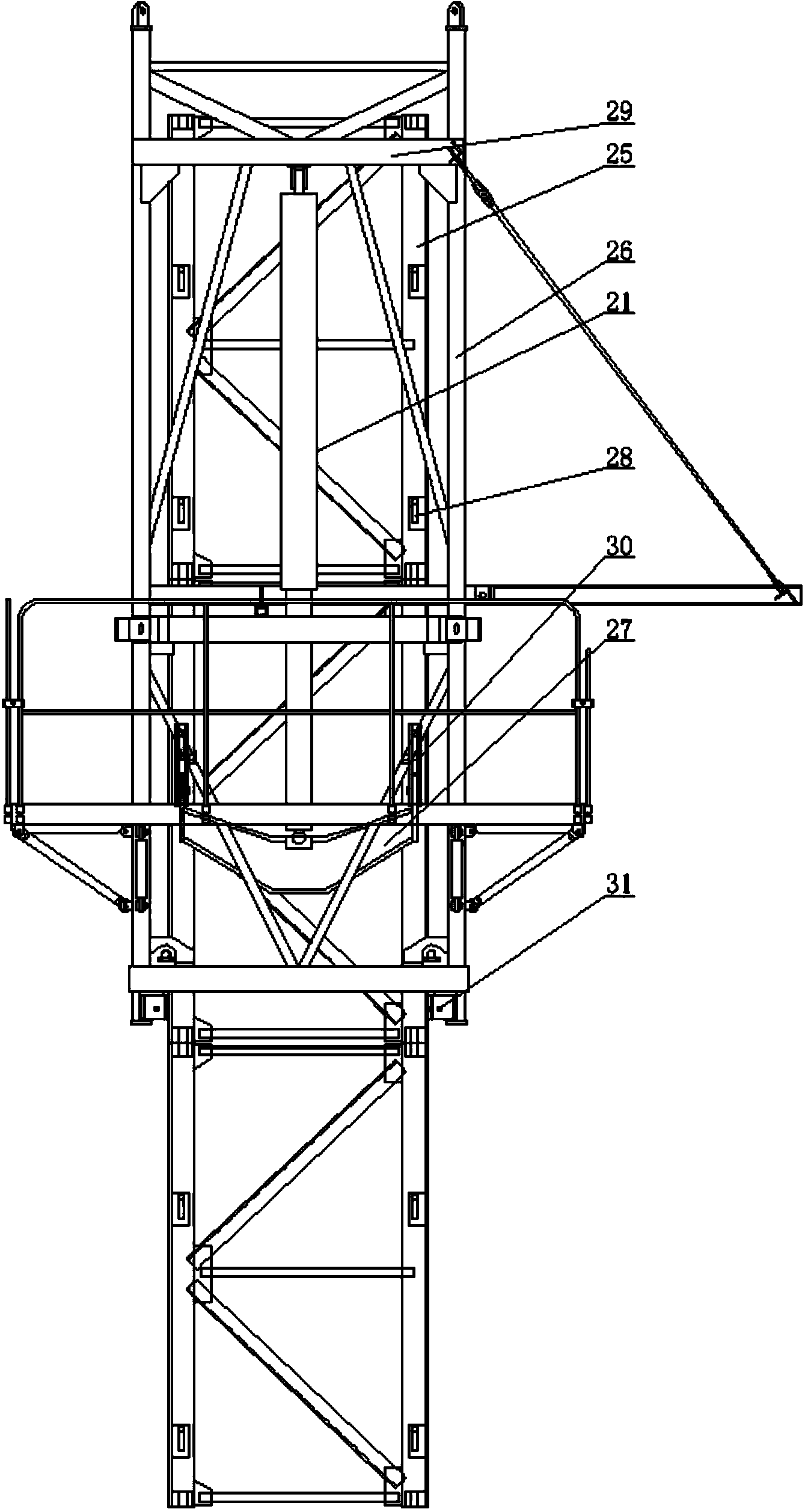

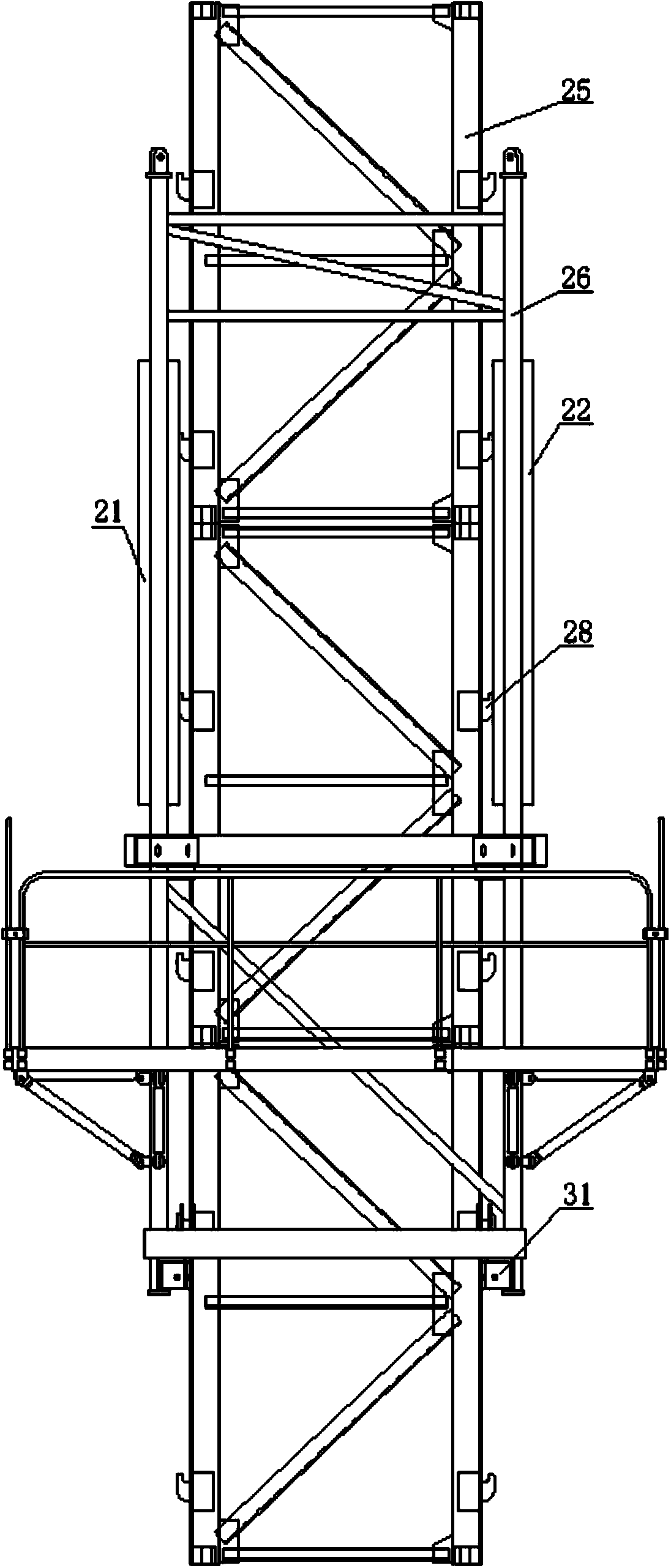

[0043] The reference signs in the 4 drawings of this embodiment are as follows: fuel tank 1, filter 2, engine 3, one-way quantitative pump 4, first overflow valve 5, third electromagnetic reversing valve 6, pilot overflow valve 7. Pressure gauge 8, accumulator 9, stop valve 10, first electromagnetic reversing valve 11, first hydraulic control check valve 12, PLC controller 13, second electromagnetic reversing valve 14, first check valve 15a, the second one-way valve 15b, the third one-way valve 15c, the fourth one-way valve 15d, the speed regulating valve 15e, the fifth one-way valve 16a, the sixth one-way valve 16b, the seventh one-way valve 16c, the Eight one-way valves 16d, electromagnetic speed regulating valves 16e, second hydraulically controlled one-way valves 17, third hydraulically controlled one-way valves 18, fourth hydraulically controlled one-way valves 19, fifth hydraulically controlled one-way valves 20, working cylinders 21. Spare oil cylinder 22, first positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com