Digital intelligent rope controller

A technology of rope arranging device and coupling, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of high cost and price, manual commutation, large wear of double-headed screw, etc., and achieves simple structure and convenient installation. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

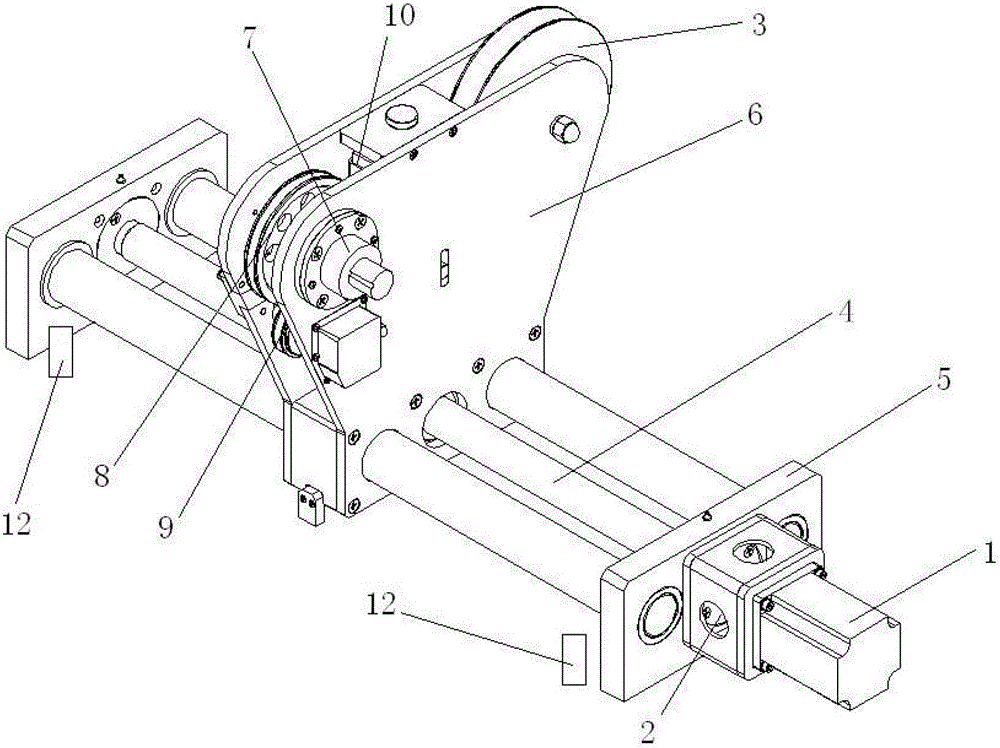

[0023] This embodiment describes a digital intelligent rope arranging device, and its overall structure is as follows figure 1 As shown, it includes a stepping motor 1, a coupling 2, a lead screw 4, a guide wheel 3, a metering wheel 8, a rotary encoder 7 and a body 6. The stepping motor 1 is connected to the lead screw 4 through the coupling 2 The screw 4 is fixed between two parallel screw support plates 5, and the two ends of the screw 4 of the rope arranging device are respectively provided with position sensors 12 for detecting the position of the body 6 of the rope arranging device.

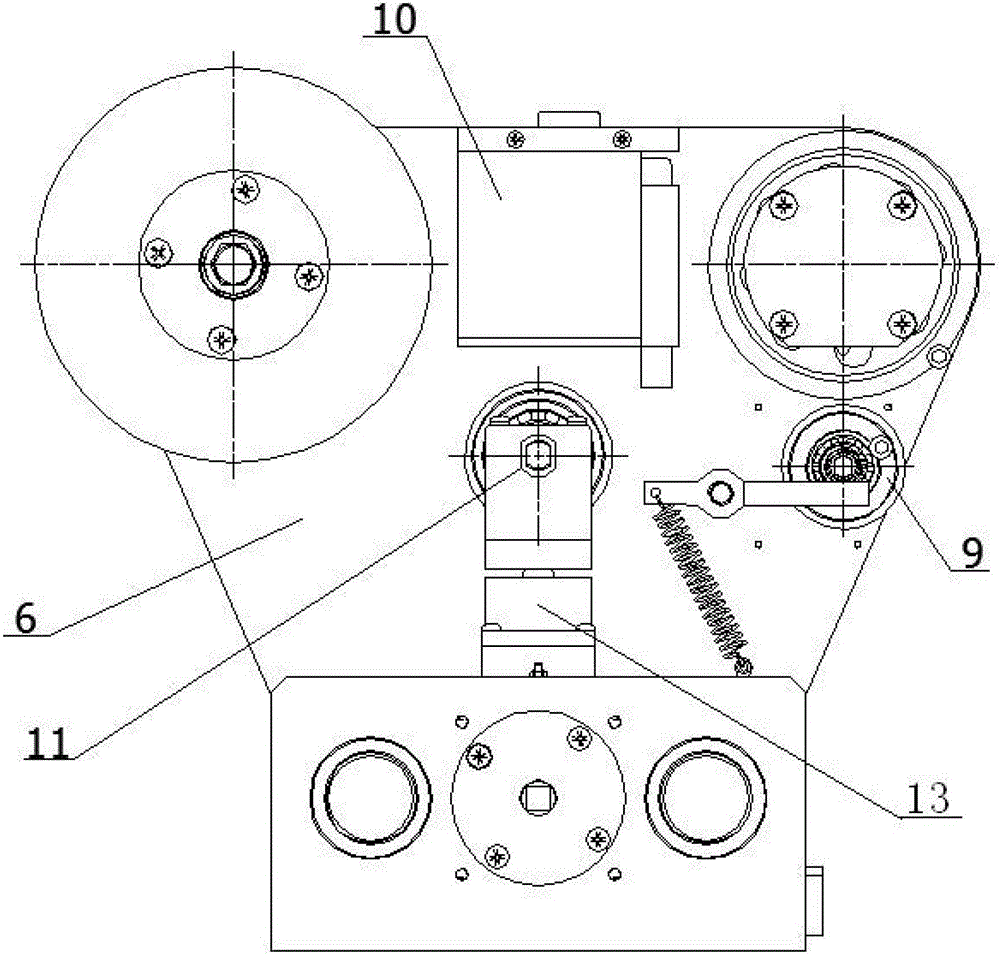

[0024] The body 6 is arranged on the screw 4 and the body 6 can move left and right along the screw 4. The structure of the body 6 and its upper components is as follows figure 2 As shown, the guide wheel 3 and the metering wheel 8 are arranged on the two top corners of the fuselage 6 in parallel. The rotary encoder 7 is connected to the metering wheel 8 through the coupling 2, and the guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com