Method for preparing completely dispersed alpha aluminum oxide nano particles

A technology of α-alumina and nano-particles, which is applied in the field of inorganic materials, can solve the problems of large particle size, high phase transition temperature, and poor dispersion, and achieve the effect of small size, low calcination temperature, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the molar ratio of iron ions and aluminum ions at 5:1 and the concentration of aluminum ions at 0.02 mol / L, appropriate amounts of aluminum nitrate and iron nitrate were weighed and dissolved in deionized water. Then titrate the mixed solution to pH 7 with 3 mol / L ammonia water, and continue to stir for 0.5 h. The precipitate was filtered, washed with deionized water and absolute ethanol, and dried at 60°C to obtain the precursor. The precursor was put into a tube furnace, calcined to 620 °C at a rate of 3 °C / min, kept for 2 h, and cooled naturally. The calcined powder was corroded in a reaction kettle with 4 mol / L hydrochloric acid at a temperature of 100°C. Finally, the remaining precipitates in the reactor were washed by centrifugation with 4 mol / L hydrochloric acid and absolute ethanol, respectively, to obtain α-alumina nanoparticles.

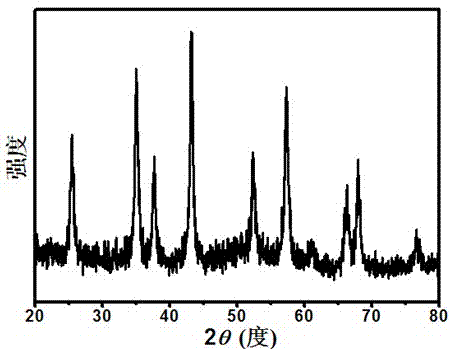

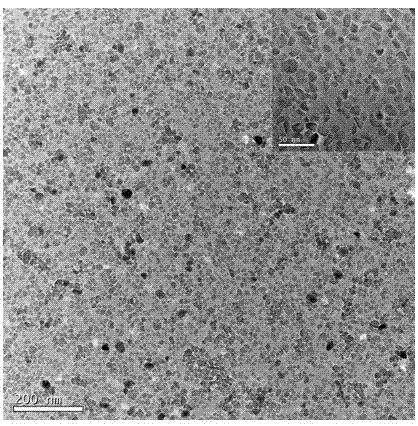

[0018] The obtained α-alumina nanoparticles have an average particle size of 14 nm, a particle size distribution of ...

Embodiment 2

[0020] According to the molar ratio of iron ions and aluminum ions at 5:1 and the concentration of aluminum ions at 0.02 mol / L, appropriate amounts of aluminum nitrate and iron nitrate were weighed and dissolved in deionized water. Then titrate the mixed solution to pH 7 with 3 mol / L ammonia water, and continue to stir for 0.5 h. The precipitate was filtered, washed with deionized water and absolute ethanol, and dried at 60°C to obtain the precursor. The precursor was put into a tube furnace, calcined to 660 °C at a rate of 3 °C / min, kept for 2 h, and cooled naturally. The calcined powder was corroded in a reaction kettle with 4 mol / L hydrochloric acid at a temperature of 100°C. Finally, the remaining precipitates in the reactor were washed by centrifugation with 4 mol / L hydrochloric acid and absolute ethanol, respectively, to obtain α-alumina nanoparticles.

[0021] The obtained α-alumina nanoparticles have an average particle size of 23 nm, a particle size distribution of ...

Embodiment 3

[0023] According to the molar ratio of iron ions and aluminum ions at 7:1, and the concentration of aluminum ions at 0.02 mol / L, appropriate amounts of aluminum nitrate and iron nitrate were weighed, and dissolved in deionized water. Then titrate the mixed solution to pH 7 with 3 mol / L ammonia water, and continue to stir for 0.5 h. The precipitate was filtered, washed with deionized water and absolute ethanol, and dried at 60°C to obtain the precursor. The precursor was put into a tube furnace, calcined to 660 °C at a rate of 3 °C / min, kept for 2 h, and cooled naturally. The calcined powder was corroded in a reaction kettle with 4 mol / L hydrochloric acid at a temperature of 100°C. Finally, the remaining precipitates in the reactor were washed by centrifugation with 4 mol / L hydrochloric acid and absolute ethanol, respectively, to obtain α-alumina nanoparticles.

[0024] The obtained α-alumina nanoparticles have an average particle size of 25 nm, a particle size distribution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap