Adhesive of carbon brick of blast-furnace crucible and thermocouple and filling method thereof

A technology of thermocouples and blast furnaces, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems that the temperature measured by the thermocouple cannot truly reflect the temperature of carbon bricks, cannot be cured, and has poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

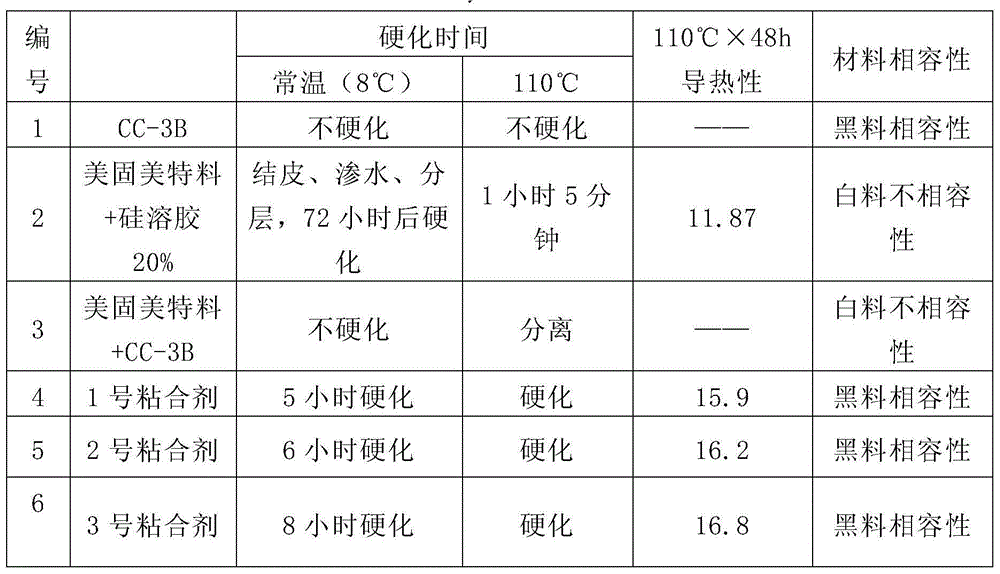

Examples

Embodiment Construction

[0015] The binder of the blast furnace hearth carbon brick and the thermocouple of the present invention is anhydrous carbonaceous binder material, including 70-80% electric calcined anthracite, 1.5-2.5% quartz, 7-9% p-toluene expressed in volume percentage Sulfonic acid reagent, 10-12% thermosetting phenolic or anhydrous resin, 5.5-8.5% ethanol or toluene diluent.

[0016] And the adhesive filling method of blast furnace hearth carbon brick and thermocouple of the present invention may further comprise the steps:

[0017] A. Drill holes in the lower part of the hearth of the blast furnace to the required depth. The required depth is 150mm-250mm drilled into the carbon brick;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com