Rapeseed oil residue recycling segregation pot

A rapeseed oil and pot body technology, applied in recycling technology, fatty material recovery, recovery of fat oil/fatty acid from waste, etc., can solve the problems of affecting oil refining effect, uneven heating, serious heat loss, etc. Small loss, simple structure improvement and energy saving effect

Inactive Publication Date: 2014-02-12

SICHUAN DEYANG NIANFENG FOOD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Rapeseed oil will produce a lot of oil feet after precipitation treatment, so it is necessary to recycle the oil feet. The traditional treatment method is mainly to use boilers for refining. The main disadvantages of direct heating of boilers are: the heating is not uniform enough, which affects the oil refining effect ; Heat loss is serious, which is not conducive to saving energy, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

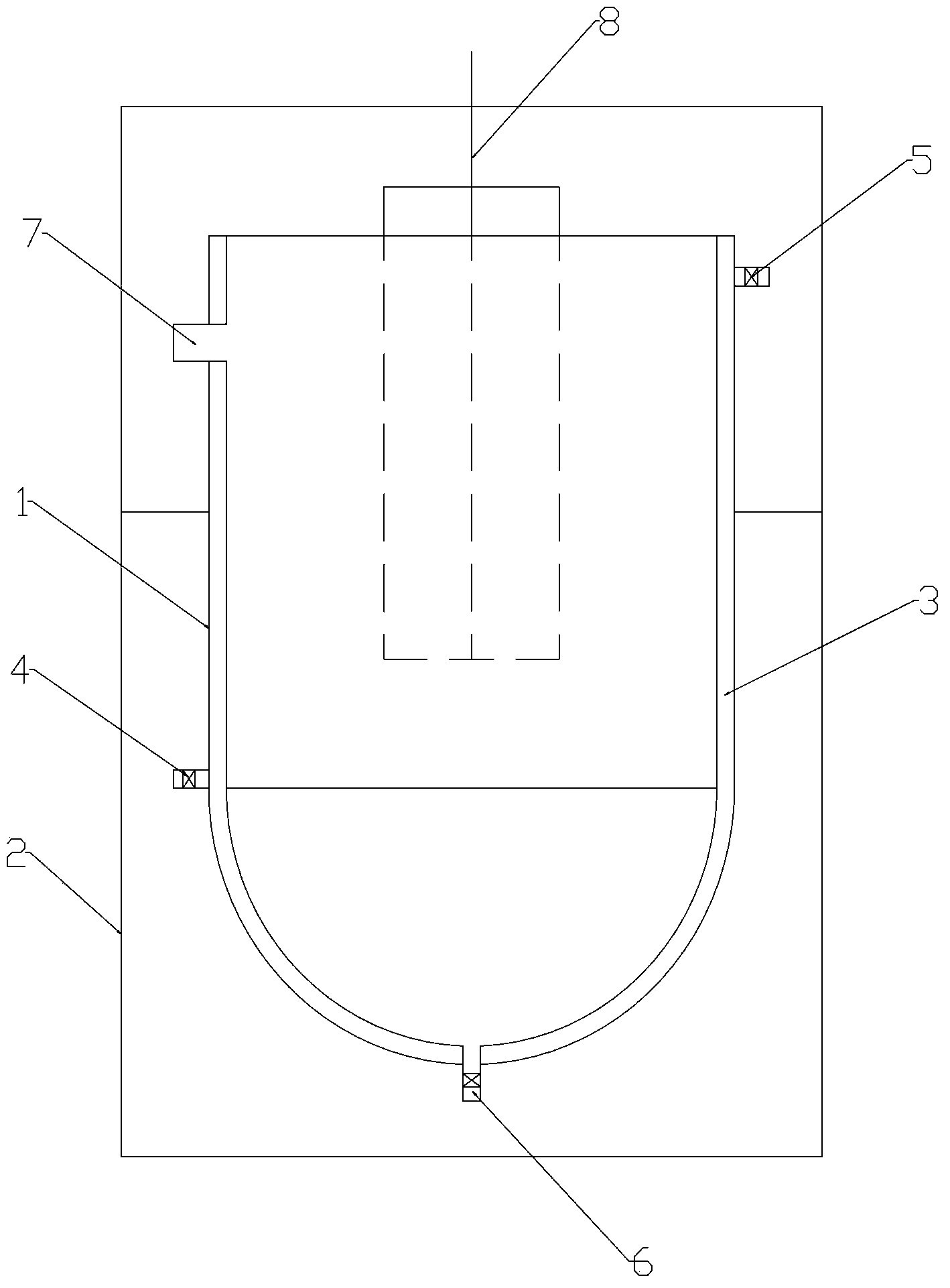

The invention discloses a rapeseed oil residue recycling segregation pot comprising a pot body and a pot rack, the pot body wall is provided with a steam interlayer, a gas intake valve and a gas discharge valve, the lower end of the pot body is provided with a water discharge port, and the upper part of the pot body is provided with an oil suction port. According to the rapeseed oil residue recycling segregation pot, by arrangement of the steam interlayer on the pot body wall, rapid and uniform heating of oil residues in the pot can be achieved by steam, oil can be fast separated for recovery, at the same time, a steam heating mode is high in thermal efficiency and little in heat loss, precious energy can be saved, and the cost of production can be effectively reduced.

Description

technical field [0001] The invention relates to a device for recovering rapeseed oil legs, in particular to a recovery and separation pot for rapeseed oil legs. Background technique [0002] Rapeseed oil will produce a lot of oil feet after precipitation treatment, so it is necessary to recycle the oil feet. The traditional treatment method is mainly to use boilers for refining. The main disadvantages of direct heating of boilers are: the heating is not uniform enough, which affects the oil refining effect ; Heat loss is serious, which is not conducive to saving energy. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a rapeseed oil foot recovery and separation pot with uniform heating and good energy saving effect. [0004] In order to solve the above-mentioned technical problems, the present invention adopts the following technical scheme: a kind of rapeseed oil leg recovery and separation pot, including a pot ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11B13/02

CPCY02W30/74

Inventor 王安体王长严朱目成

Owner SICHUAN DEYANG NIANFENG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com