Rotor composite yarn spinning device

A composite yarn and rotor technology, which is applied in spinning machines, open-end spinning machines, and continuously wound spinning machines, etc., can solve the problem that the fiber strength cannot be fully utilized, and the appearance and strength of rotor spinning yarns are affected. problems, to achieve the effect of increasing aesthetics, reducing the formation of straddling fibers, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

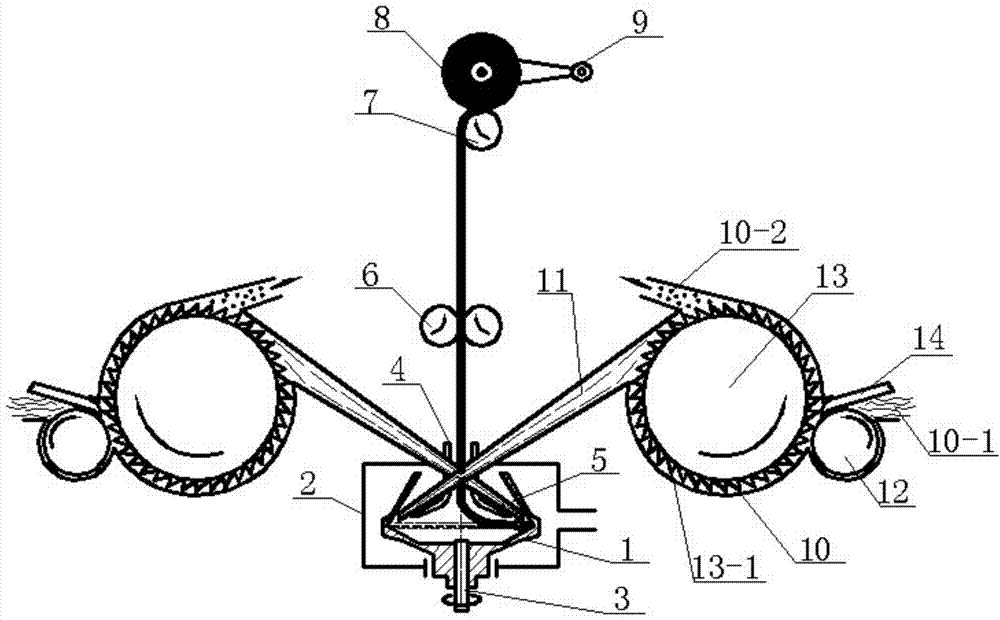

[0022] Such as figure 1 As shown, a rotor composite yarn spinning device includes a cohesive twisting mechanism, a winding forming mechanism, and a feeding and carding mechanism; two feeding and carding mechanisms are symmetrically arranged on both sides of the cohesive and twisting mechanism.

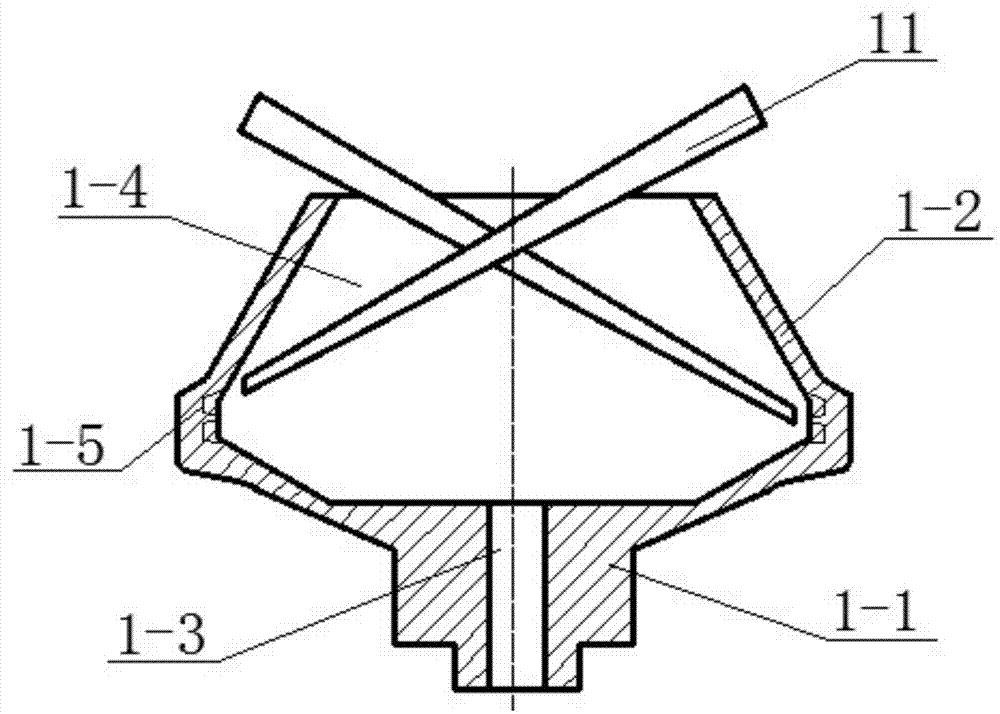

[0023] Such as figure 1 and 2 As shown, the cohesive twisting mechanism includes a spinning cup 1, an air suction device 2, a guide tube 3, a yarn guide tube 4 and a twist disc 5. The spinning cup 1 includes a cup holder 1-1 and a cup body 1-2 which are integrally formed and arranged coaxially. The cup holder 1-1 is arranged at the bottom of the cup body 1-2; The wire pipe installation hole 1-3; the upper part of the cup body 1-2 is an upright truncated cone shape, and the lower part is an inverted truncated cone shape, and a cavity 1-4 consistent with the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com