Air filter for working machine engine

An air filter and engine technology, which is applied in the direction of machines/engines, engine components, combustion air/combustion-air treatment, etc., can solve the problems of filter element filtration performance reduction, clogging, and filtration performance degradation, etc., to achieve improvement Durable life, improved durability, anti-clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below based on the drawings.

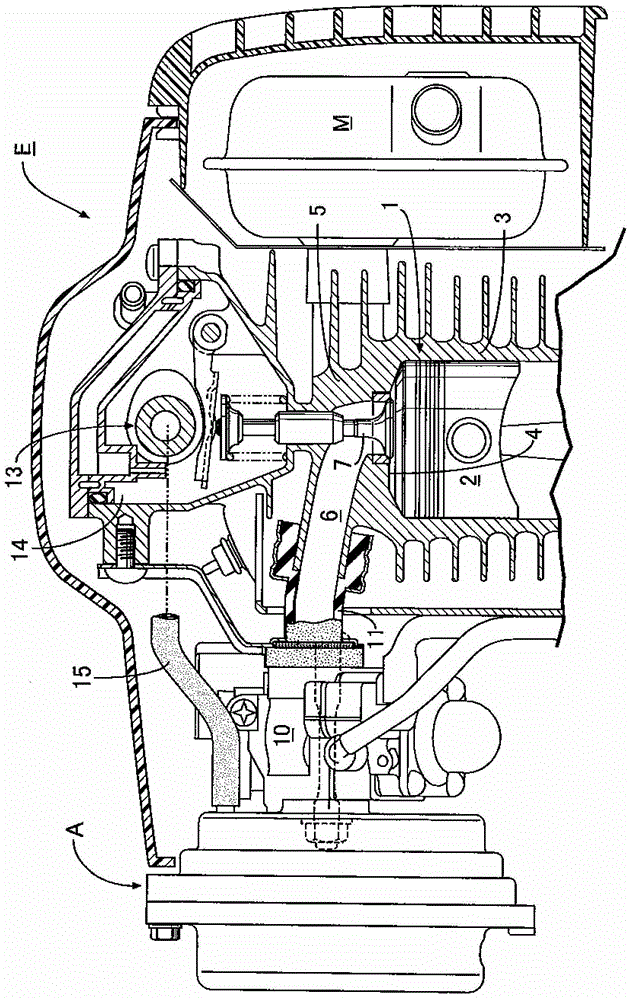

[0036] exist figure 1 In the figure, symbol E is a hand-held four-stroke engine as an engine for a work machine, which is attached to a drive unit of the power trimmer T as a power source of the power trimmer T, for example. With regard to the power trimmer T, since the cutter C is used in various directions depending on the working state, the engine E is also greatly tilted or reversed, and its operating posture is always changed.

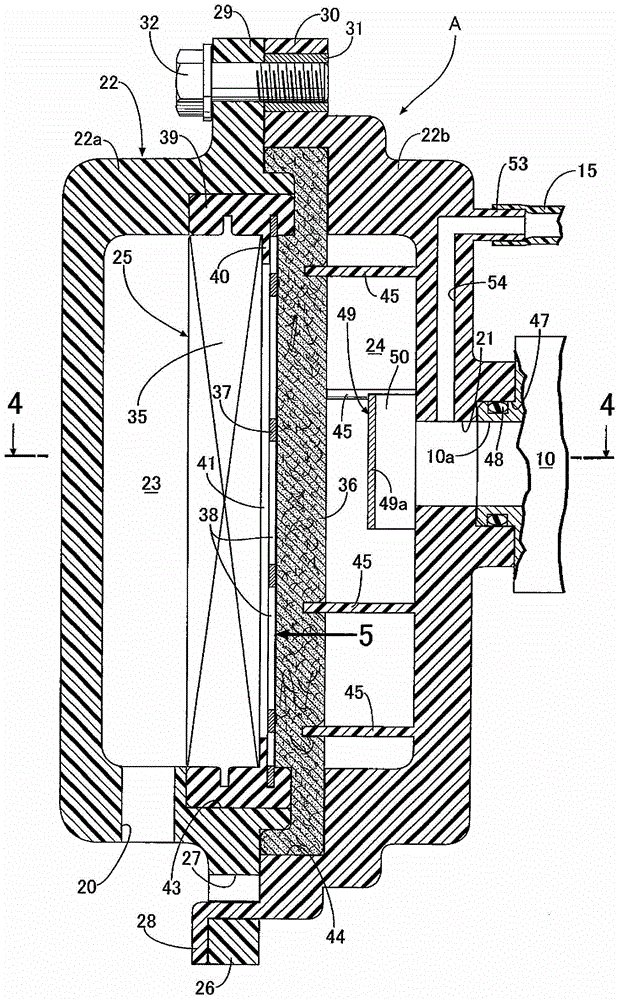

[0037] like figure 2 As shown, the engine main body 1 of the above-mentioned engine E is configured such that the cylinder block 3 and the cylinder head 5 are integrated, the cylinder block 3 is embedded with the piston 2, and the cylinder head 5 has a top surface facing the piston 2. The combustion chamber 4 is provided on the cylinder head 5 with an intake port 6 and an exhaust port (not shown) respectively opening in the combustion chamber 4; and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com