Rise rivet nut fastener

A fastener and riveting technology, applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems of inability to guarantee riveting strength, insufficient torque resistance, blank nut connection, etc., and achieve good electrical contact performance and flatness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

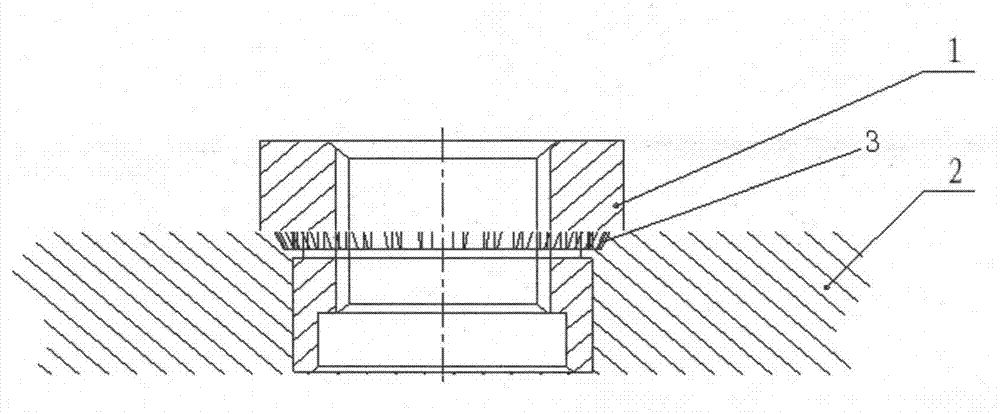

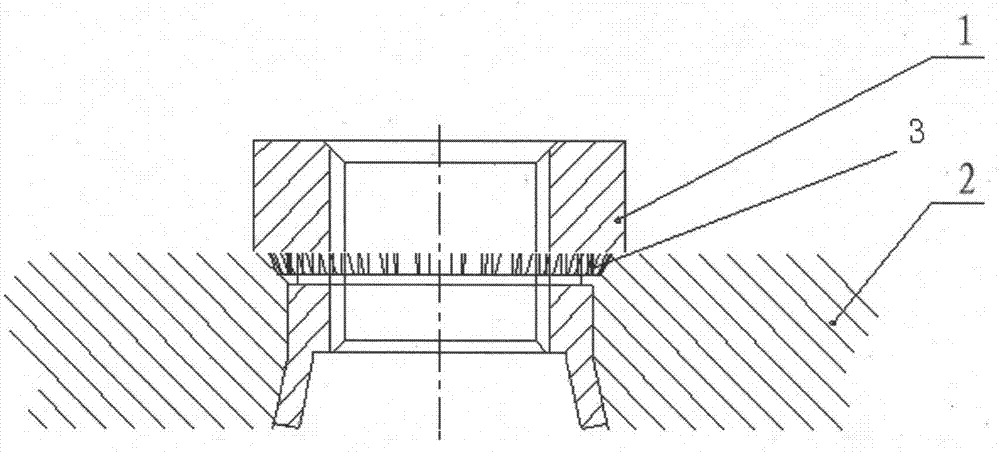

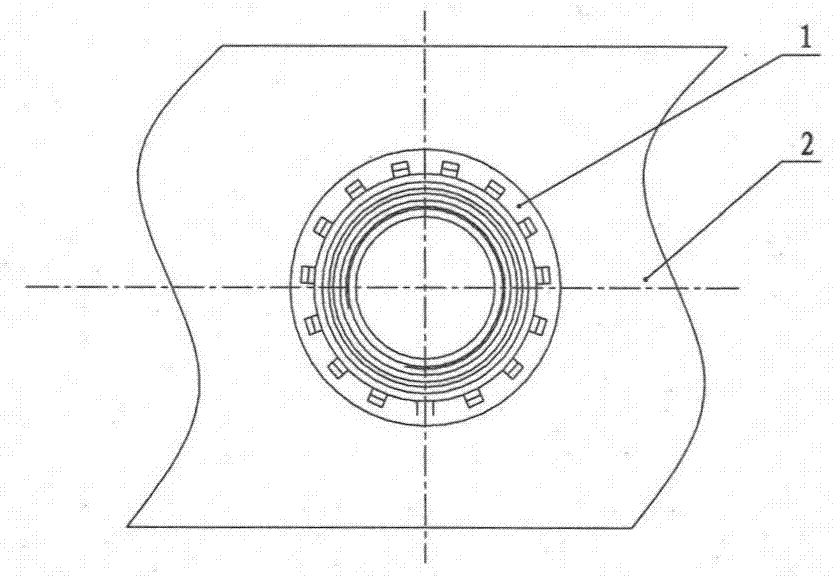

[0010] Such as Figure 1 to Figure 3 As shown, a rivet nut fastener provided by the present invention includes a main body 1, the rivet part of the main body 1 extends into the processed product 2, and trapezoidal teeth are formed on the joint surface 3 of the main body 1 and the processed product 2 Teeth or triangular teeth, there is a circular groove 4 below it, and the height of the riveted part is 0.5-1mm smaller than the thickness of the processed product 2, so that the design can meet the connection strength.

[0011] First put the rivet nut fastener provided by the present invention into the corresponding hole of the processed product 2, and it is necessary to make a tapered jig that matches the type of the rivet nut fastener, and then press it with a riveting machine. The contact surface of the rivet nut is in full contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com