Valve

A technology for valve elements and loading valves, which is applied in the field of valves, can solve the problems of large valve shells, etc., and achieve the effects of reducing volume, simplifying space, and reducing manufacturing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

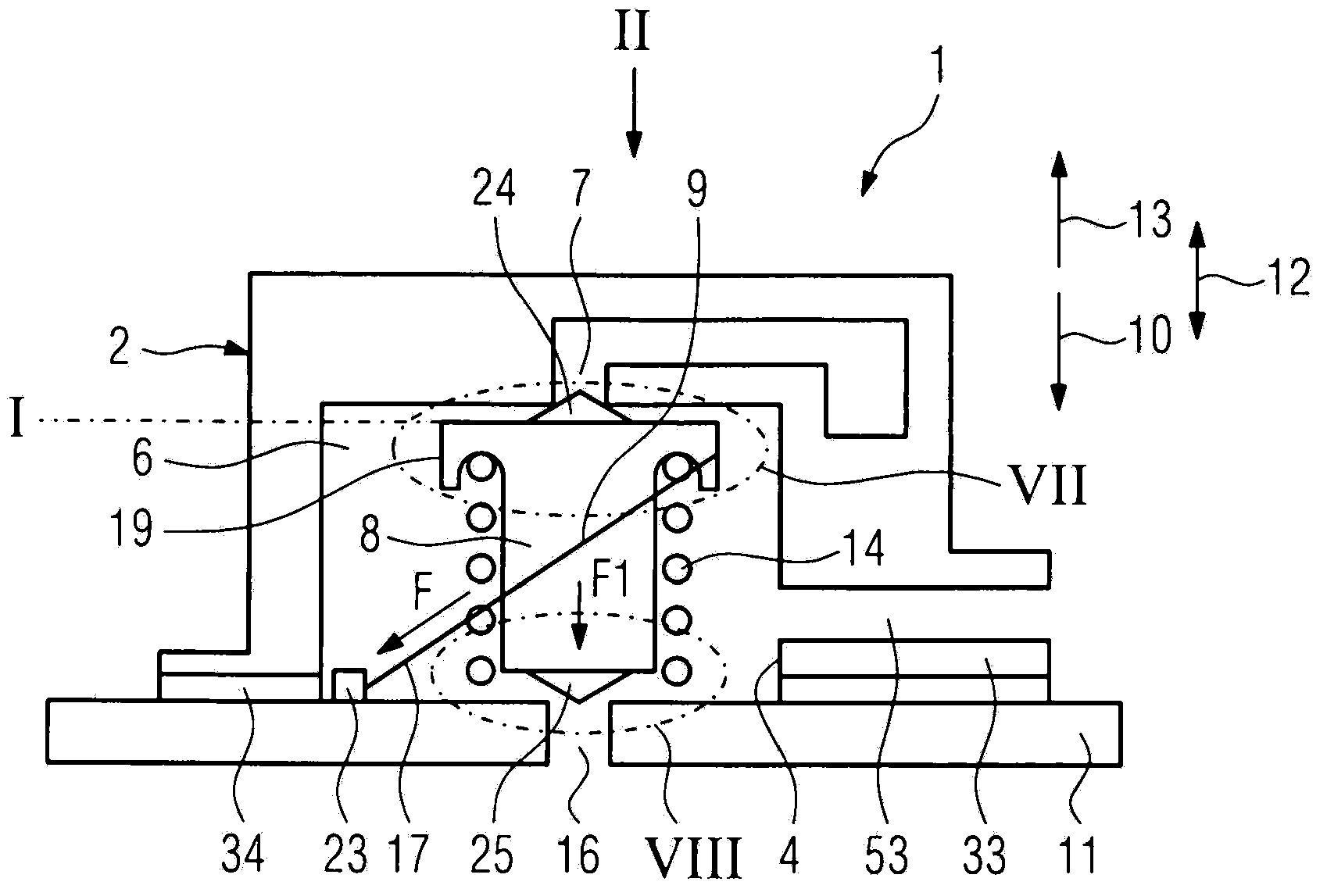

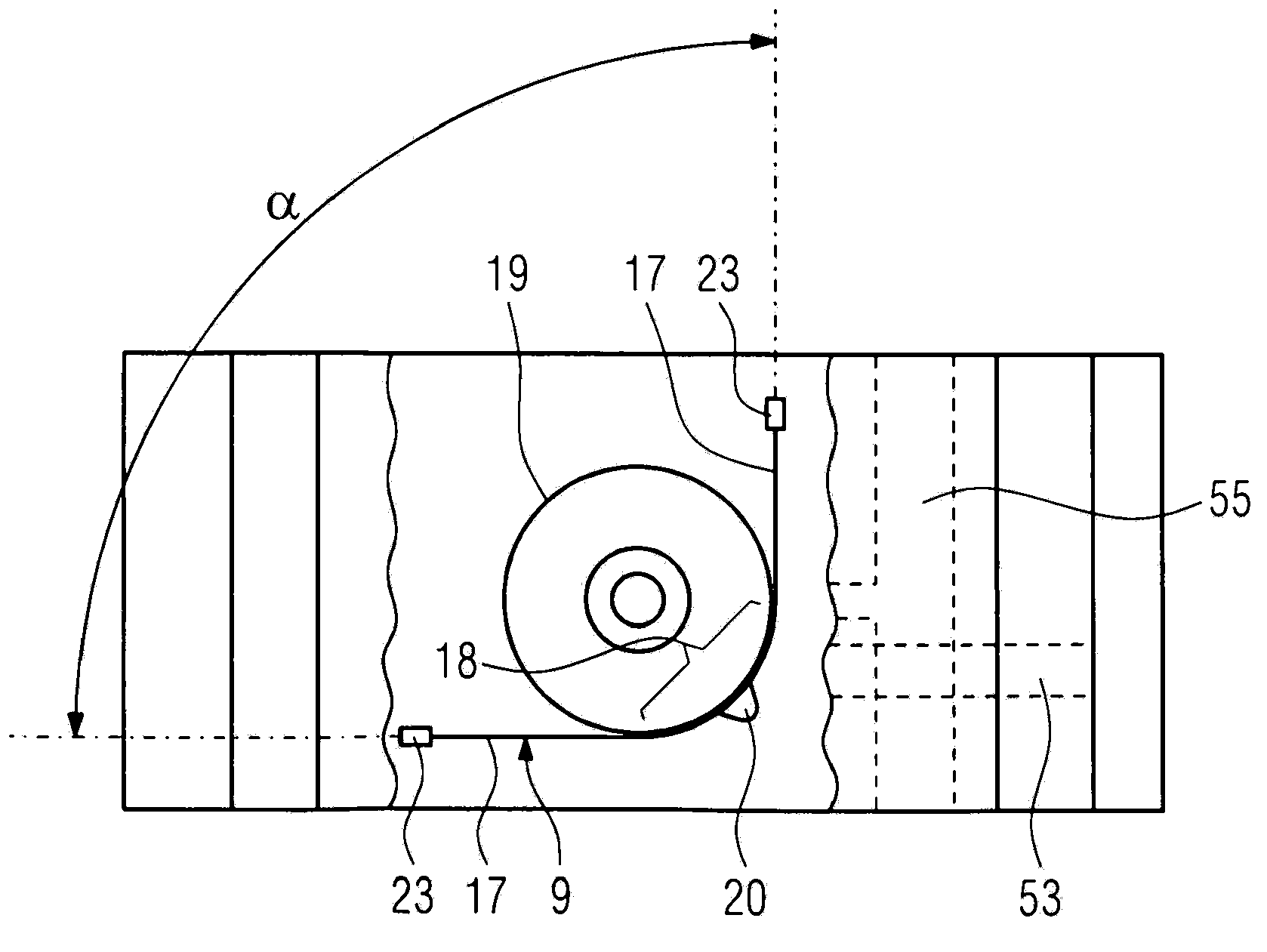

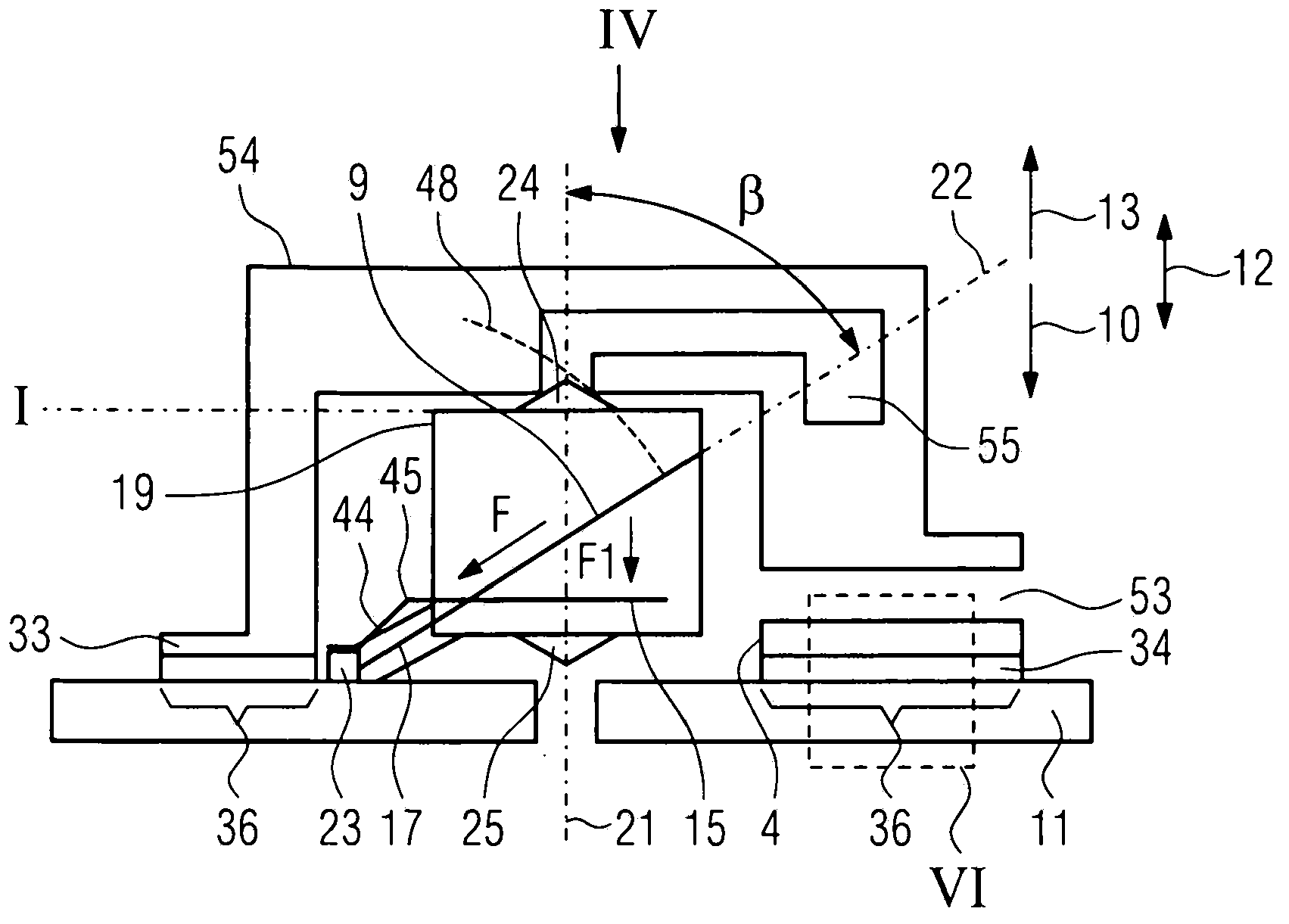

[0017] in Figure 1 to 4 The valve 1 shown in FIG. 1 includes a housing 2 formed by a housing cover 3 and a circuit board 11. One side of the housing cover 3 is open, that is, an opening 4 is provided in one side of the housing cover 3, and the opening is blocked by the circuit board 11. In a valve arrangement structure 5 ( Figure 5 In the case of ), the opening 4 of each valve is blocked by a common circuit board 4a, that is, by a partial area thereof. The internal space of the housing 2 thus formed encloses a pressure chamber 6. In the housing cover 3 there is a first medium opening 7 which opens into the pressure chamber 6. Liquid or gas is considered as the medium, where in the following reference is made to a pneumatic valve and the medium is air. In the pressure chamber 6 there is a valve element 8 which can move between a first position I and a second position II, in which the valve element closes the first medium opening 7 ( figure 1 with 3 ), the valve element rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com