Water temperature and water level sensor and production method thereof

A water temperature and water level sensor technology, which is applied in the field of sensors, can solve problems such as water inflow, affecting the normal operation and service life of the water temperature and water level sensor, and the connection of the insulating silicone tube is easy to crack, so as to achieve firm connection, improve service life and performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

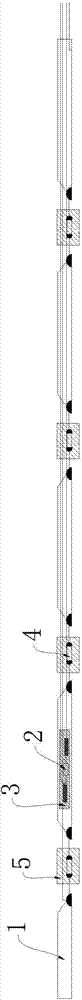

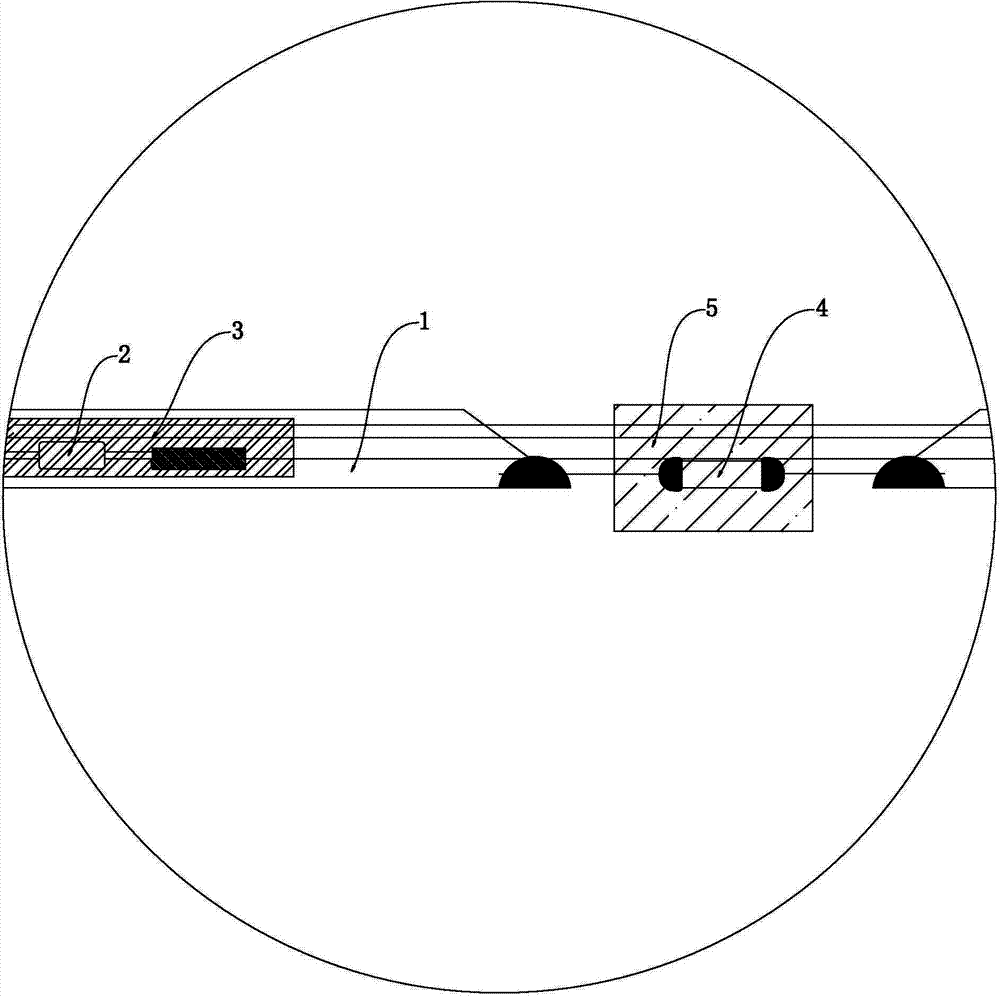

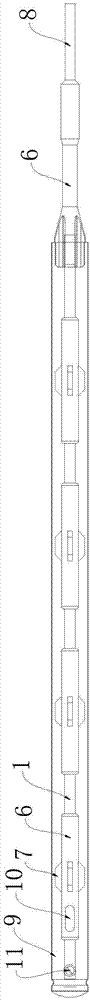

[0018] Such as figure 1 , figure 2 , image 3 As shown, the water temperature and water level sensor described in this embodiment includes a resistor 4, a thermistor 2, a stainless steel outer tube 9 and a multi-section stainless steel tube 1, and the adjacent two ports of the two adjacent stainless steel tubes 1 are inclined planes. A nickel sheet is spot-welded on the oblique section, and a resistance 4 is welded between two adjacent sections of stainless steel pipe 1. The resistance 4 is welded on the nickel sheet, and a high-temperature wire is welded in the stainless steel pipe 1 at the top and end respectively, and the high-temperature wire passes through Pass through each stainless steel tube 1 from the stainless steel tube 1 at the end, weld high-temperature wires at both ends of the thermistor 2, set the thermistor 2 in the second section of the stainless steel tube 1 at the top, and the thermistor 2 The high-temperature wire passes through the inside of the stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com